Methods for using parallel flow reactor having improved thermal control

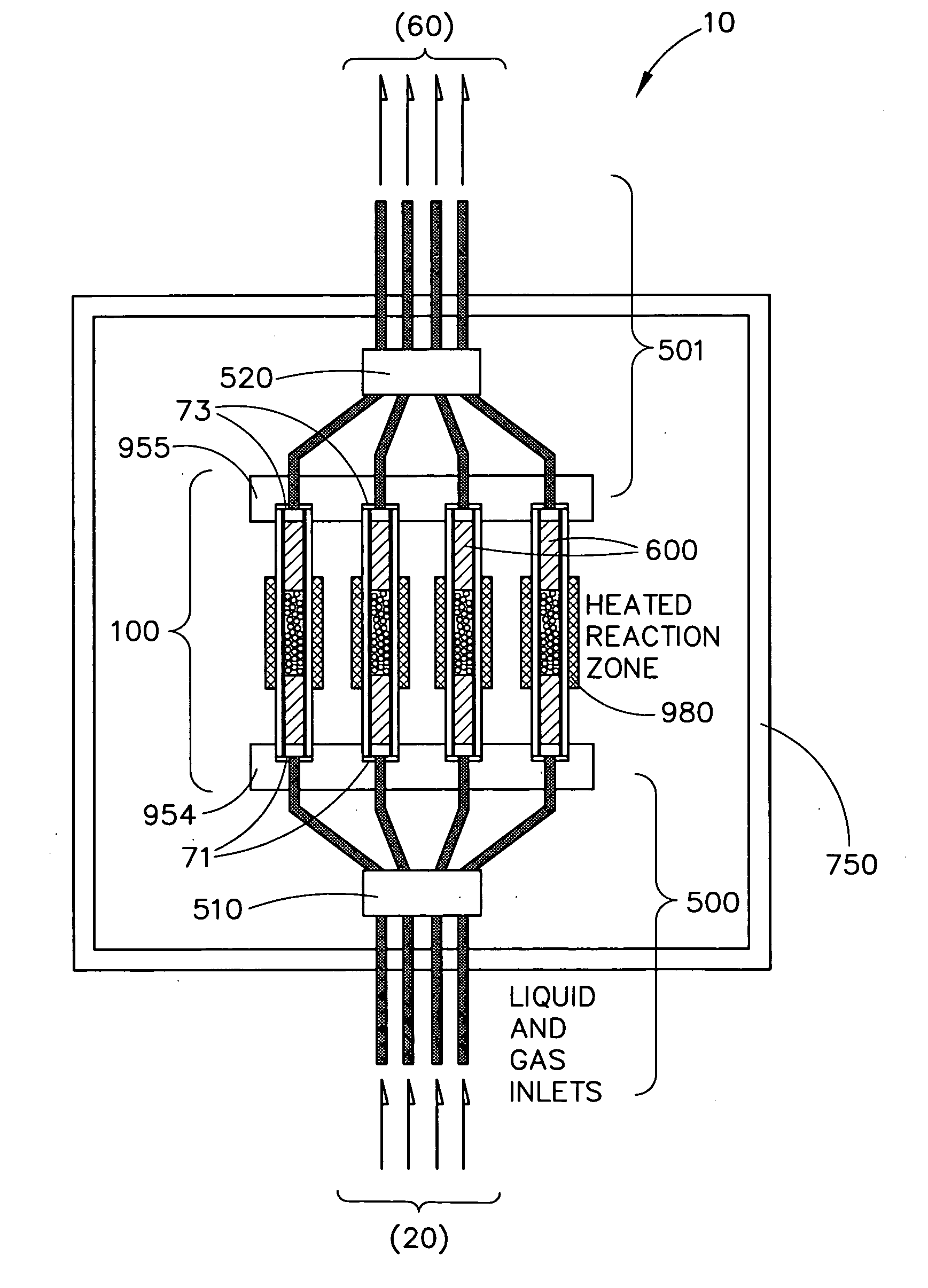

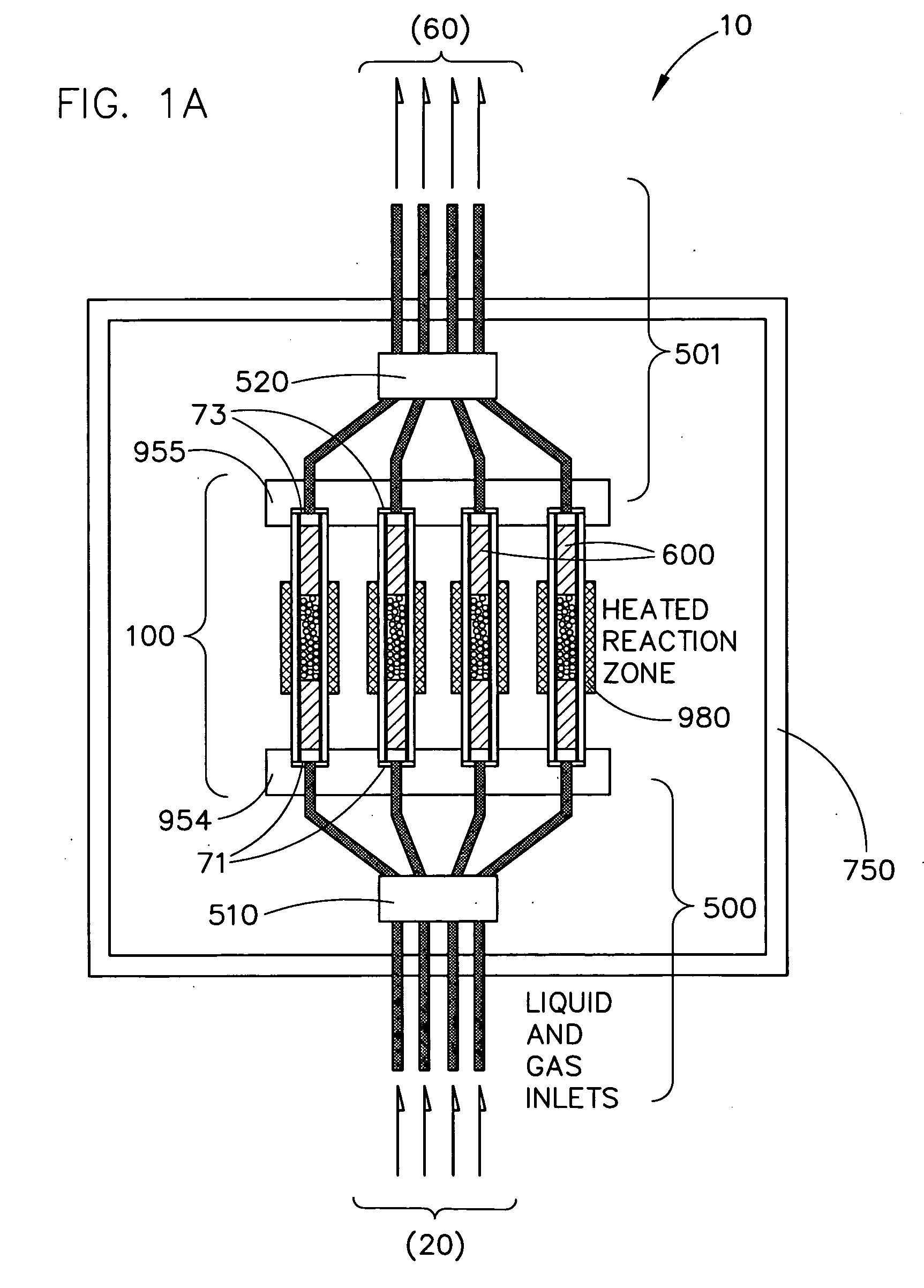

a technology of thermal control and parallel flow reactor, which is applied in the field of combinatorial (i. e., high throughput) materials science research, can solve the problems of significant thermal cross-talk between reaction vessels, limited attention, and other reactor designs known in the art that do not specifically address approaches or contemplate apparatus for investigating and/or optimizing reactions, etc., to achieve efficient identification and/or optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

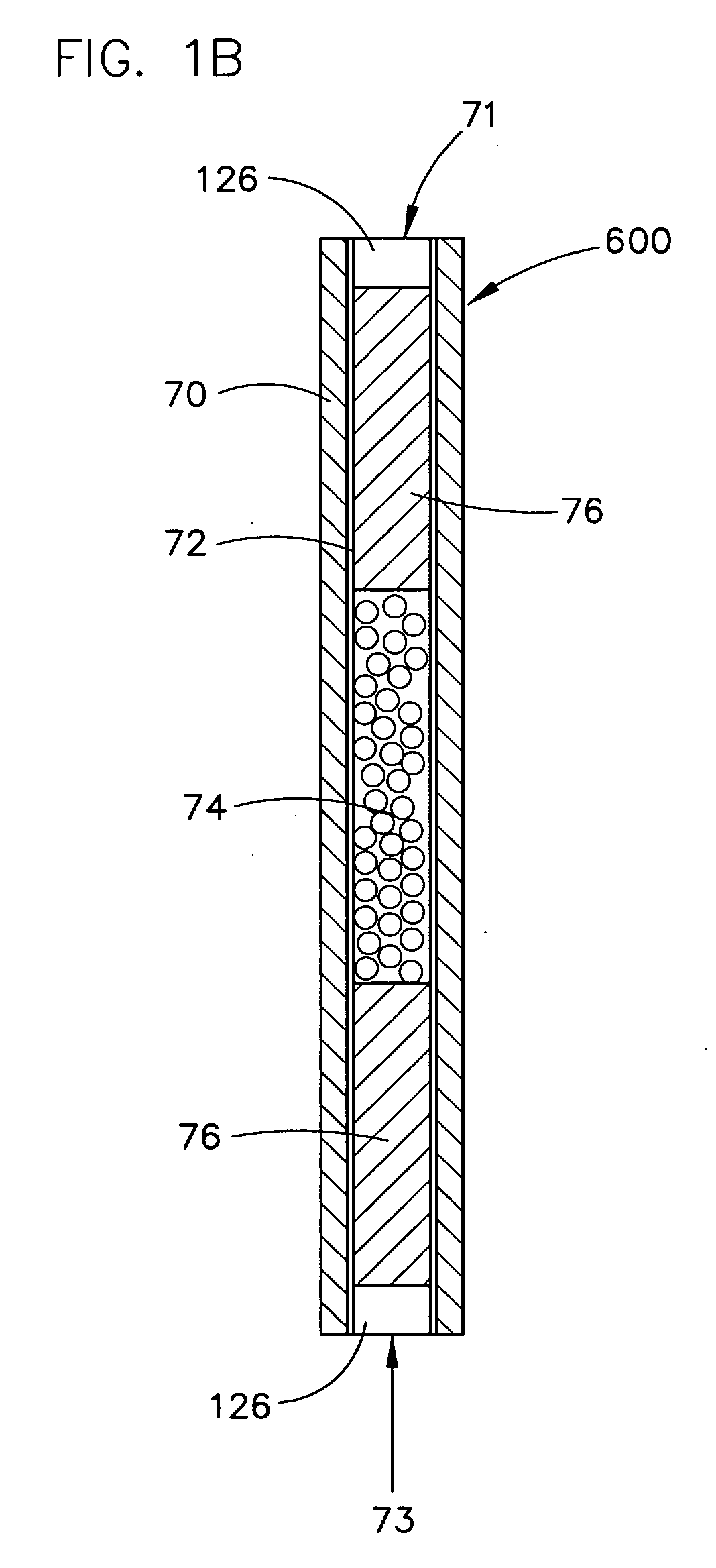

[0020] The present invention is related to the following patents and / or patent applications, each of which is hereby incorporated by reference for all purposes, including for the purpose of combination of various features disclosed in the various related applications to various features disclosed herein, to the highest extent practical, based on the knowledge in the art, and coupled with the guidance of this application and the related applications: (1) co-owned U.S. patent application Ser. No. 60 / 187,566 entitled “Apparatus and Methods for Multi-Variable Optimization of Reaction Systems and Other Chemical Processing Microsystems”, filed Mar. 7, 2000 by Bergh et al., (2) co-owned U.S. patent application Ser. No. 60 / 229,984 entitled “Apparatus and Methods for Optimization of Process Variables in Reaction Systems and Other Chemical Processing Systems”, filed Sep. 2, 2001 by Bergh et al; (3) co-owned U.S. Pat. No. 6,149,882 to Guan et al. entitled “Parallel Fixed-Bed Reactor and Fluid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com