Method and device for controlling the transition between normal operation and overrun fuel cut-off operation of an otto engine operated with direct fuel injection

a technology of direct fuel injection and transition between normal operation and overrun fuel cutoff operation, which is applied in the direction of electric control, ignition automatic control, machines/engines, etc., can solve the problems of reducing the efficiency of combustion, reducing the internal cooling of the cylinder, and reducing the amount of air taken in, so as to avoid unwanted torque jump and slow build up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

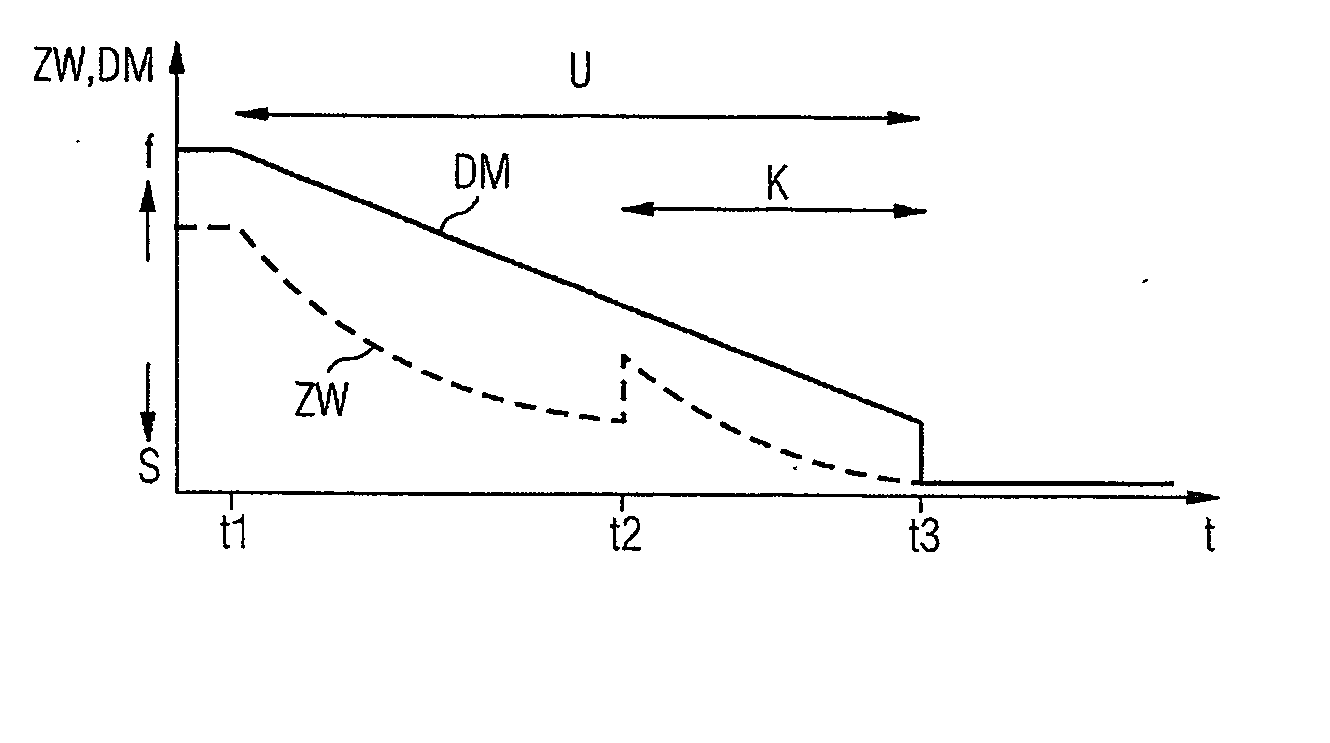

[0020] The diagram in FIG. 1 shows the schematic sequence of a switchover of an Otto engine, said engine being operated with direct fuel injection, from the normal operation into the overrun fuel cut-off operation. In this diagram, a time t corresponding to the angle of rotation of the crankshaft is plotted on the x-axis, while the torque and the ignition angle are plotted on the y-axis. The advance ignition f is plotted towards the top and the retarded ignition s is plotted towards the bottom. The curve DM shows the profile of the calculated torque and the curve ZW shows the profile of the current ignition angle during the switchover phase.

[0021] In the left-hand part of the diagram, the Otto engine is operated in the normal operating mode until the time point t1. According to the curve DM, the delivered torque is relatively high. Since the torque at the engine cannot be measured directly, it is usually estimated by arithmetic means with the aid of a torque model. In order to dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com