Slotted bladeless turbine disc

a turbine disc and bladeless technology, applied in the field of turbine discs, can solve the problems of large cost restrictions on the widespread use of these machines, catastrophic failures of turbine blades, and the need to shut down the whole machine, so as to reduce the efficiency of the turbine, reduce the cost of the blade disc, and improve the strength of the tab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

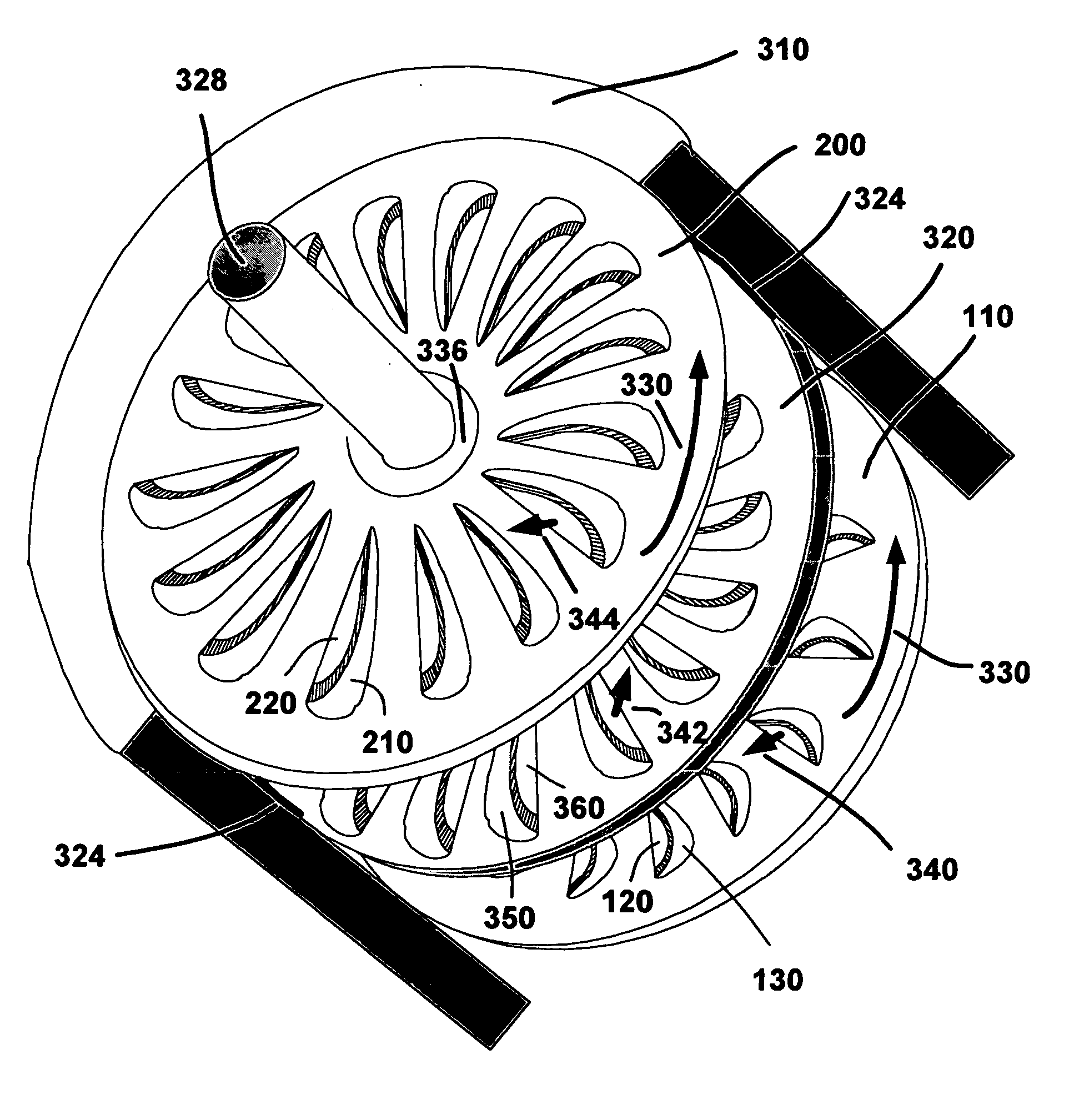

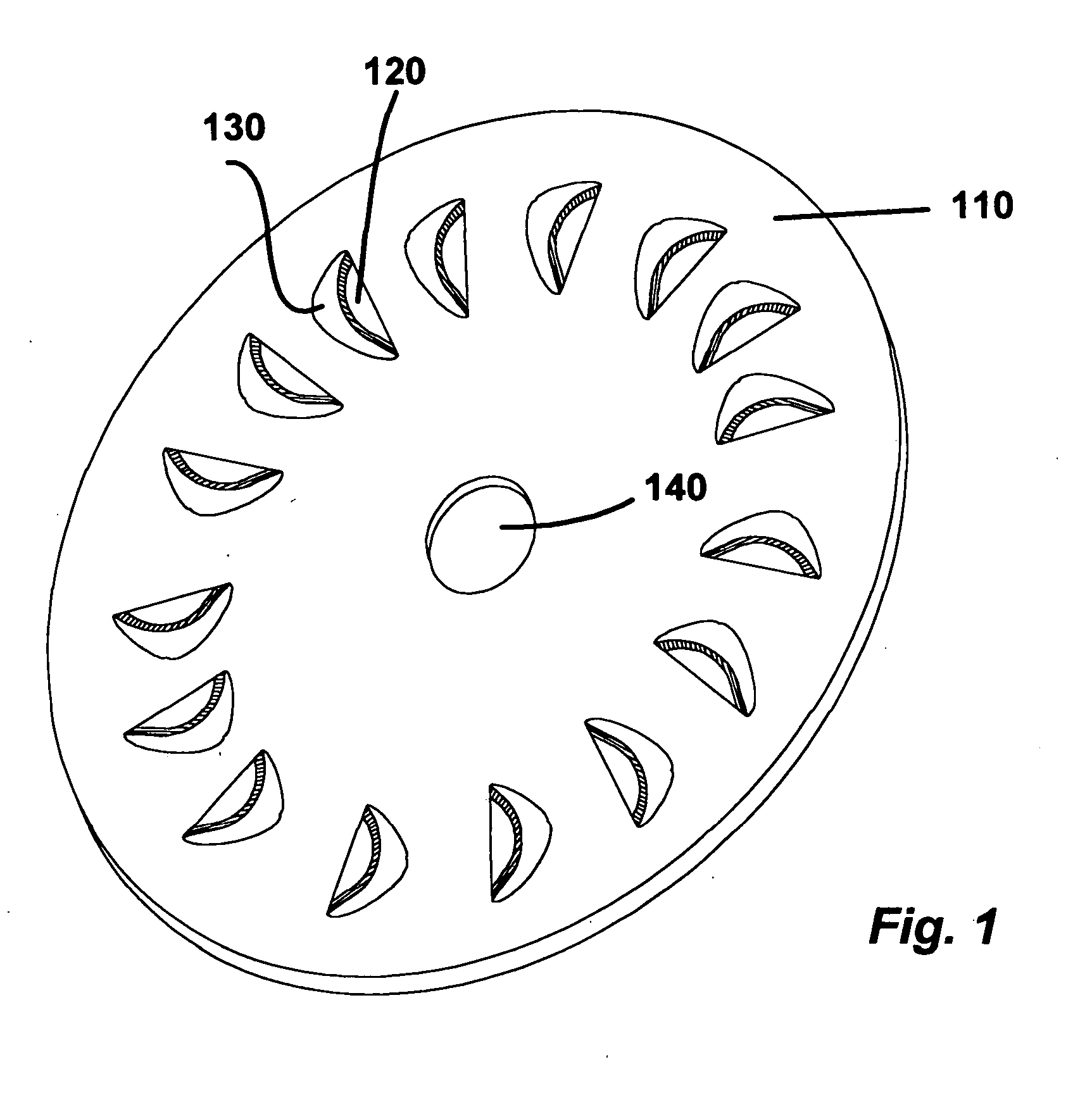

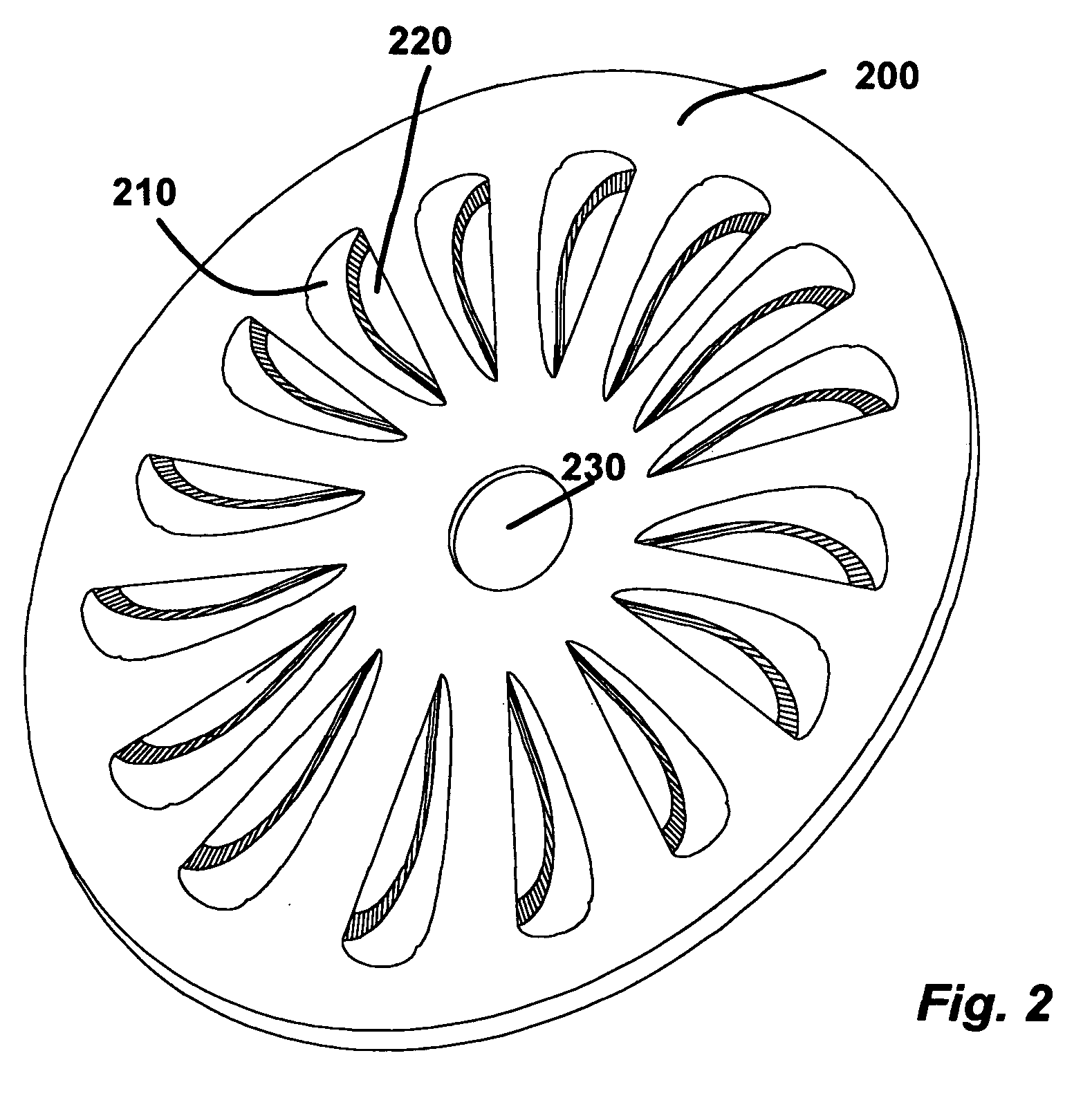

. The preferred embodiment of this invention comprises a disc with a multitude of evenly spaced slots surrounding a center hole through which a rotatable shaft is inserted; for use in steam turbines and other rotating mechanisms. The cost advantage of stamping out turbine discs over the cost of present methods of fabricating bladed turbine wheels means that stamped discs can be used to build relatively inexpensive turbines. Conversely, the high cost of fabricating bladed wheels means they can only be used in relatively high-powered expensive turbines. Using my invention small steam turbines can be fabricated primarily with stamped and welded parts that require a minimum of machining operations compared to the bladed turbine. The ability to obtain small inexpensive turbines suggests that such turbines connected to suitable electric generators may be used to power households and other facilities where electric power is not presently available or where it is cheaper to produce electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com