"run-to-run control system and operating method of the same"

a control system and run-to-run technology, applied in the direction of program control, total factory control, instruments, etc., can solve the problems of not performing the meteorology process and the optimal process recipe of the modified process recipe, and achieve the effect of optimizing the process performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In the invention, a novel run-to-run control system and a novel run-to-run controlling method are proposed. Because the tool process parameters are real-time collected during the process is performed and are regarded as the effective factors in the process for providing a optimal operation variables to the tool for the next run, the process recipe of the process is real-time changed with the process environment to obtain the optimal process performance.

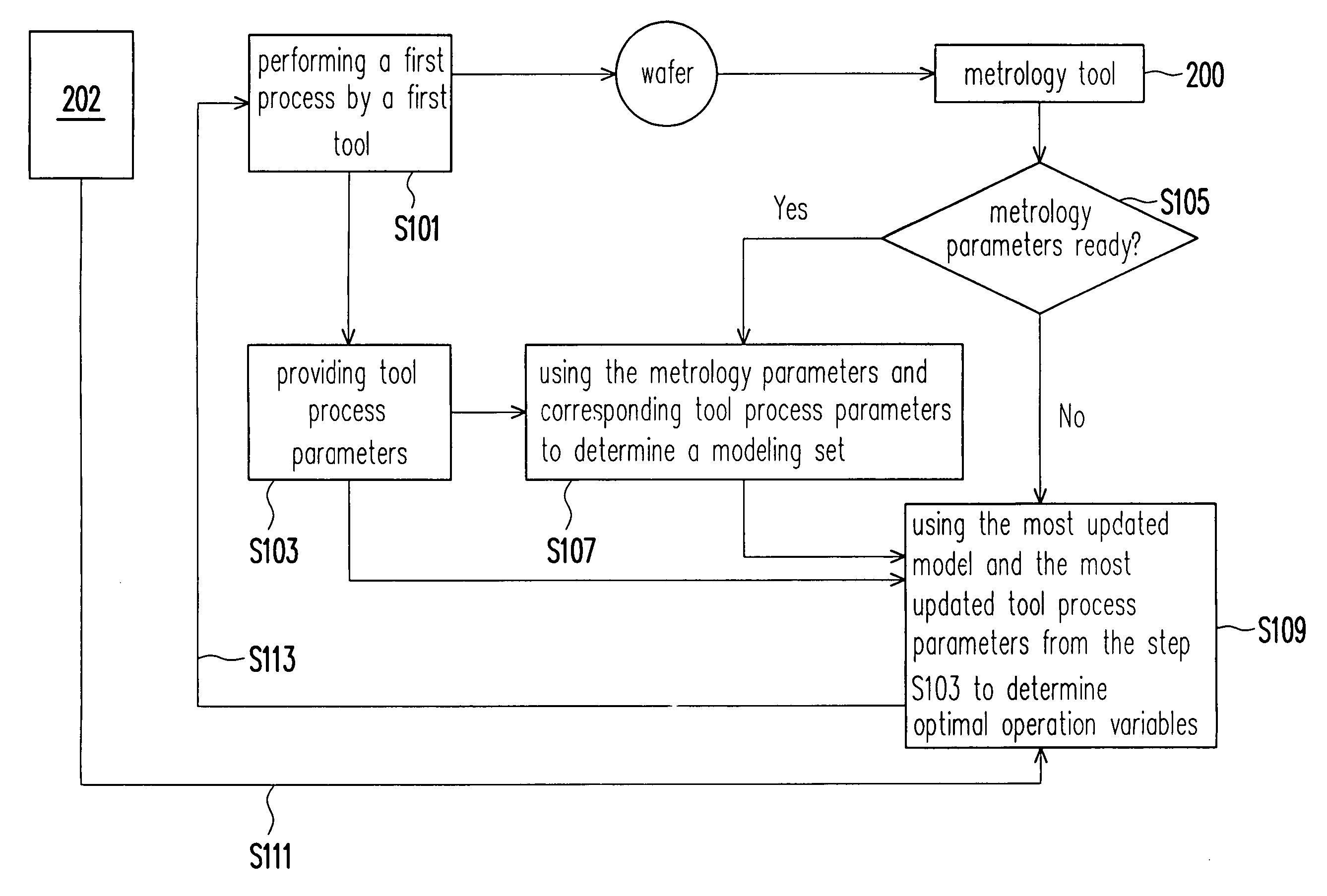

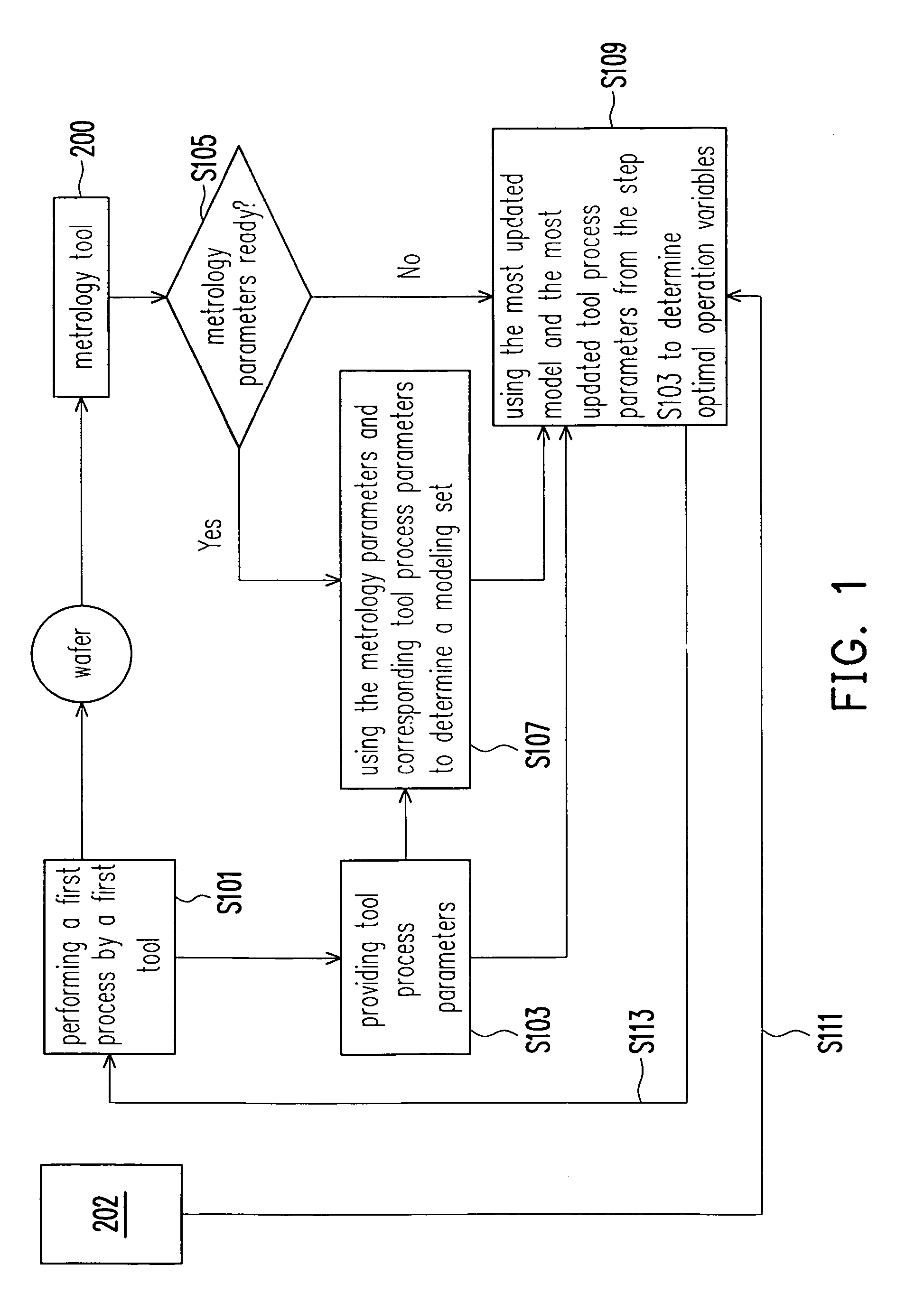

[0015]FIG. 1 is a process flow diagram, schematically illustrating a run-to-run controlling method according to one of the preferred embodiment of the present invention. As shown in FIG. 1, in the step S101, a first semiconductor process is currently preformed by a first tool for a first process run. Meanwhile, in the step S103, tool sensors (not shown) are real-time detecting a set of tool process parameters. The set of the tool process parameters characterizes a process environment during the first semiconductor process is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com