Telescopic shelter system

a shelter system and telescopic technology, applied in the field of shelter systems, can solve the problems of excessive space occupied by the shelter section, difficulty in work, and often cancelled work, and achieve the effects of preventing the separation of one shelter from another, reducing the possession space of the shelter section, and efficient use of the workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] This invention will be described in further detail by way of exemplary embodiments with reference to the accompanying drawings.

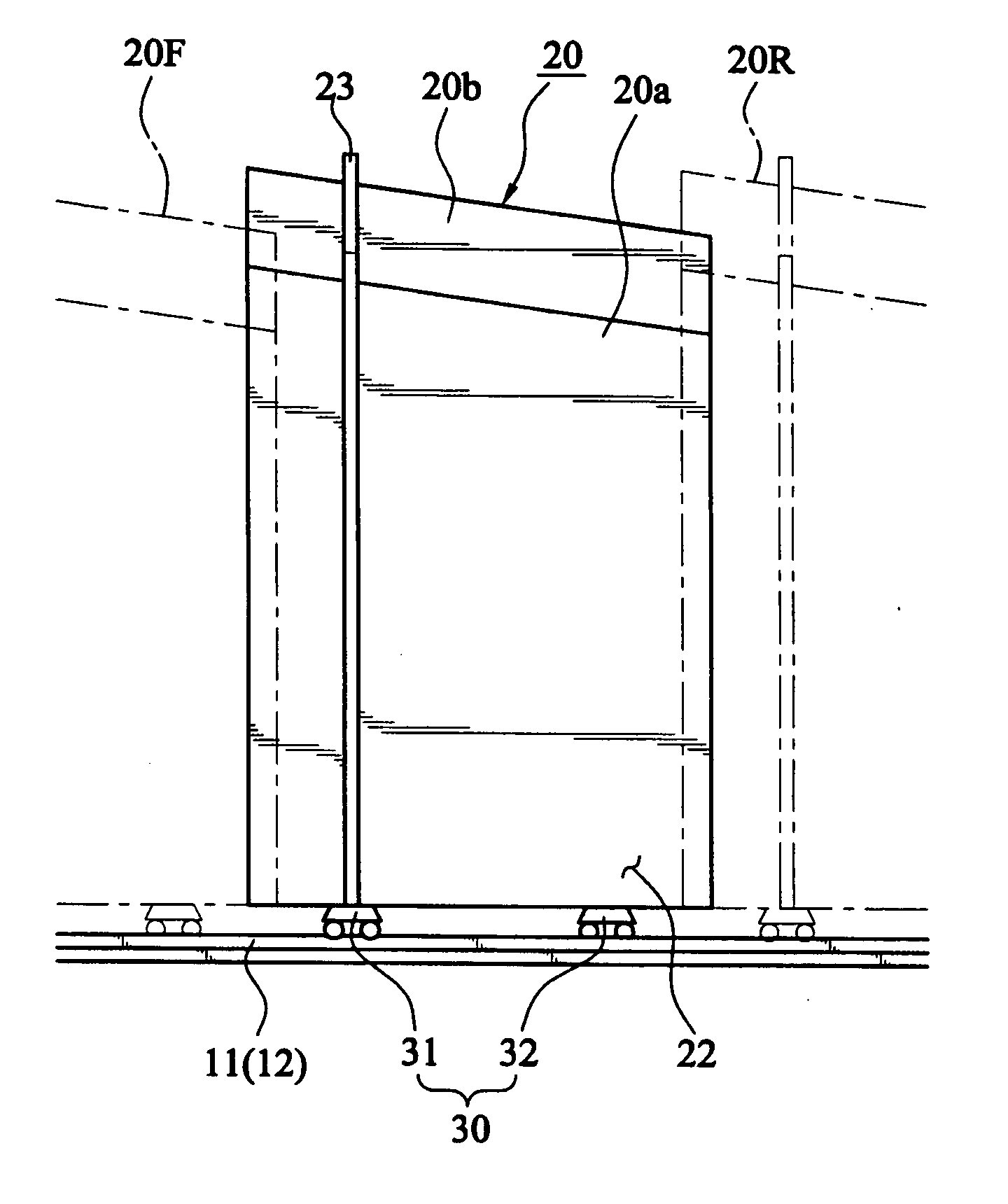

[0048] As shown in FIGS. 3A to 5, the telescopic shelter system is comprised of a guide rail 10 mounted in the ground, several shelter sections 20 arranged in a row along the guide rail 10, telescope along the guide rail 10, a number of wheels 30 provided at the lower portion of each shelter section 20 and travel on the guide rail 10, and a motor 40 mounted on the shelter section 20 for providing a clockwise / counterclockwise movement of the wheel 30.

[0049] The guide rail 10 is comprised of a pair of outer rails 11 arranged in parallel at a certain distance “s1” and a pair of parallel inner rails 12 arranged at an inner side of the outer rails 11, also at a certain distance. The interval between the outer rail 11 and the inner rail 12 exists within the slope of a side wall 20a of the shelter section 20, that is, the slope of the side wall 20a exists ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com