Cosmetic composition system with thickening benefits

a composition system and a technology of a cosmetic composition system, applied in the field of cosmetic systems, can solve the problems of easy smudging and running of the lash film on the skin around the perimeter of the eye, and affecting the smool comfort of application, so as to minimize the clumping of the lash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

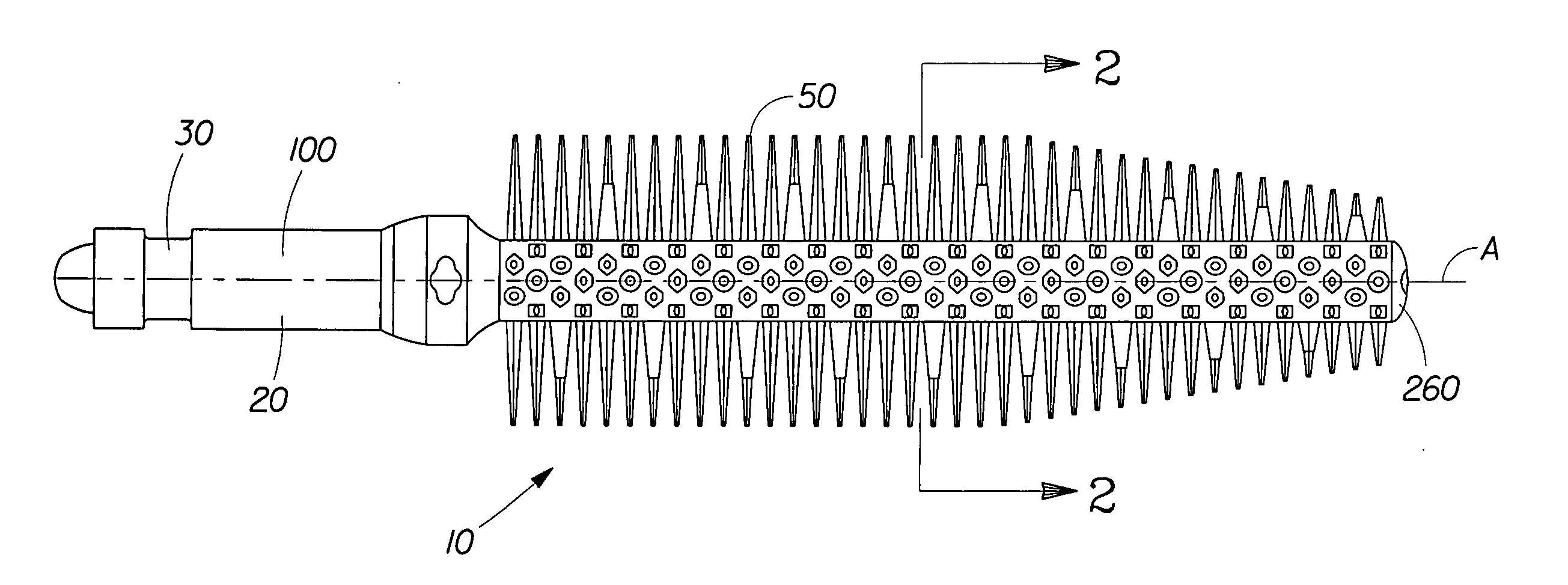

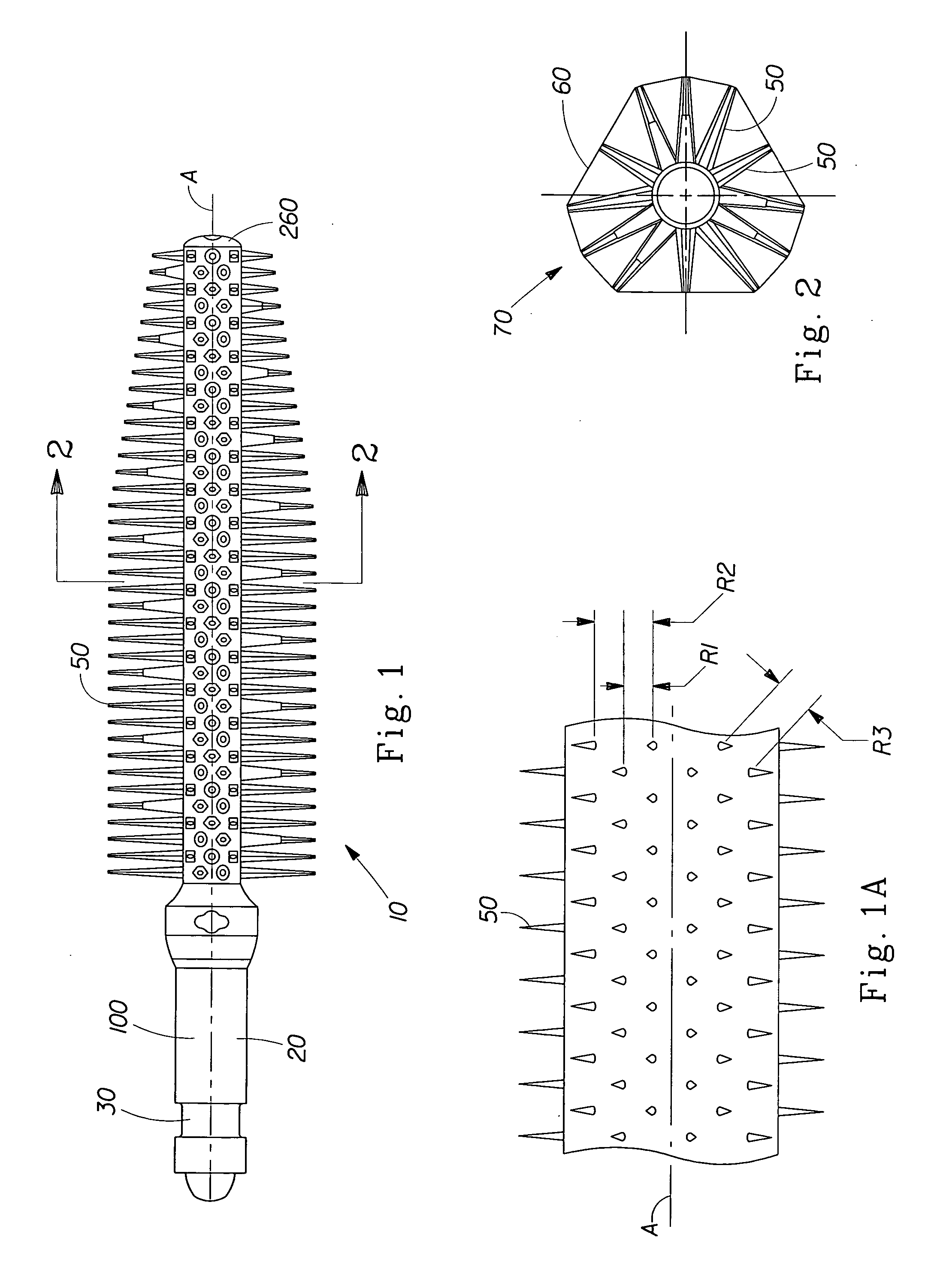

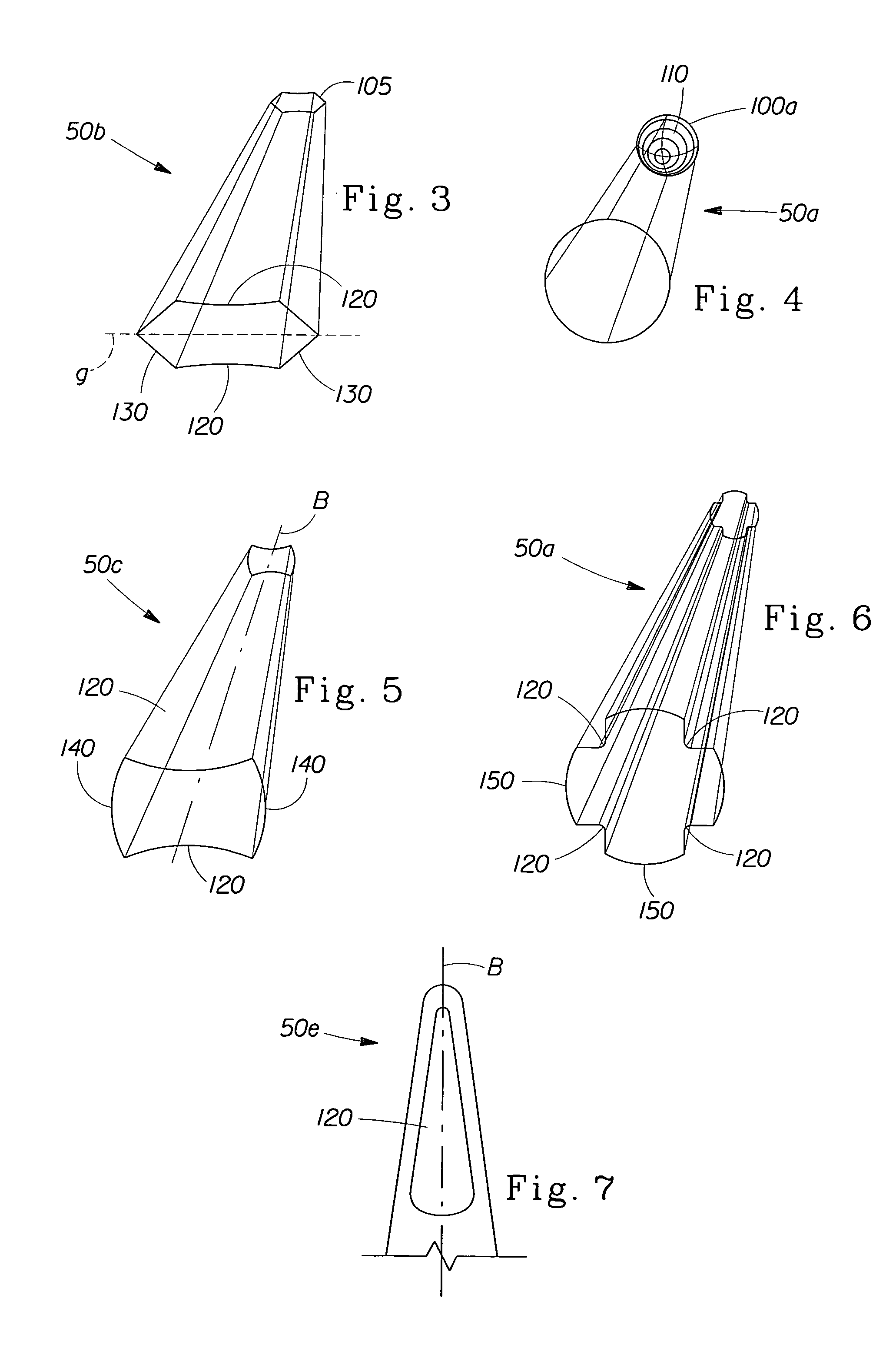

Image

Examples

example 1

Oil-in-Water Mascara Composition

[0090] A mascara containing large wax particles:

PhaseRaw MaterialWeight %AGlyceryl Monostearate5.250ABlack Iron Oxide7.250ADisteardimonium Hectorite2.250AStearic Acid2.750ACarnauba Wax2.000ATriethanolamine1.750ASynthetic Wax1.500APolyvinyl Alcohol1.500APropylene Carbonate0.750ALecithin1.250AOleic Acid 80%1.000BAcrylates Copolymer5.170BDeionized Water40.18BSimethicone Emulsion 30%0.200CXanthan Gum0.6CPropylene Glycol3.000DAmmonium Acrylates Copolymer17.79EEthyl Alcohol SD 40-B1.000EBenzyl Alcohol0.650EPanthenol0.280EPhenoxyethanol0.280EMethylparaben0.200EEthylparaben0.200EPropylparaben0.100ETrisodium EDTA0.100F20 μm Polyethylene Wax Particle3.000TOTAL100.000

Procedure

[0091] Phase A is heated to melt the waxes and allow the pigment to be dispersed with a Cowles Blade mixer. Phase B materials are stirred together at ambient conditions, and Phase C materials are stirred together at ambient conditions and then it is added to Phase B (to gel Phase B), a...

example 2

Oil-in-Water Mascara Composition

[0092] A mascara containing large hollow particles:

PhaseRaw MaterialWeight %AGlyceryl Monostearate5.250ABlack Iron Oxide7.250ADisteardimonium Hectorite2.250AStearic Acid2.750ACarnauba Wax2.000ATriethanolamine1.750ASynthetic Wax1.500APolyvinyl Alcohol1.500APropylene Carbonate0.750ALecithin1.250AOleic Acid 80%1.000BAcrylates Copolymer5.170BDeionized Water41.93BSimethicone Emulsion 30%0.200CXanthan Gum0.6CPropylene Glycol3.000DAmmonium Acrylates Copolymer17.79EEthyl Alcohol SD 40-B1.000EBenzyl Alcohol0.650EPanthenol0.280EPhenoxyethanol0.280EMethylparaben0.200EEthylparaben0.200EPropylparaben0.100ETrisodium EDTA0.100FExpancel ® DE40d601Expancel ® DE20d700.25TOTAL100.000

Procedure

[0093] Phase A is heated to melt the waxes and allow the pigment to be dispersed with a Cowles Blade mixer. Phase B materials are stirred together at ambient conditions, and Phase C materials are stirred together at ambient conditions and then it is added to Phase B (to gel Pha...

example 3

Oil-in-Water Mascara Composition

[0094] A mascara containing large polymeric particles:

PhaseRaw MaterialWeight %AGlyceryl Monostearate7.500ABlack Iron Oxide6.500AC18-36 Acid Triglyceride5.000AStearic Acid3.750ACarnauba Wax2.500AParaffin Wax2.500ATricontanyl PVP2.000ALecithin2.000APotassium Cetyl Phosphate1.000ATriethanolamine2.250BTrisodium EDTA0.100BDeionized Water34.89BSimethicone Emulsion0.200CEthyl Alcohol1.000CBenzyl Alcohol0.650CPanthenol0.280CPhenoxyethanol0.280CMethylparaben0.200CEthylparaben0.200CPropylparaben0.100CTrisodium EDTA0.100DAmmonium Acrylates Copolymer12.000Dow Corning HMW2220 Dimethicone15EmulsionTOTAL100.000

Procedure

[0095] The waxes of Phase A are heated to melt the waxes and then the pigment is added and dispersed into the waxes. Then the Triethanolamine as added and mixed in. Phase B materials are stirred together at ambient conditions, and then heated to the same temperature (˜90 C) as Phase A. Phase A and Phase B are combined together and mixed to homog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| equivalent diameter | aaaaa | aaaaa |

| equivalent diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com