System for identification of defects on circuits or other arrayed products

a technology of circuits and arrays, applied in the field of system and method for manufacturing products having arrays, can solve the problems of more defects that present an increased risk to the operation of a particular wafer, and achieve the effect of increasing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

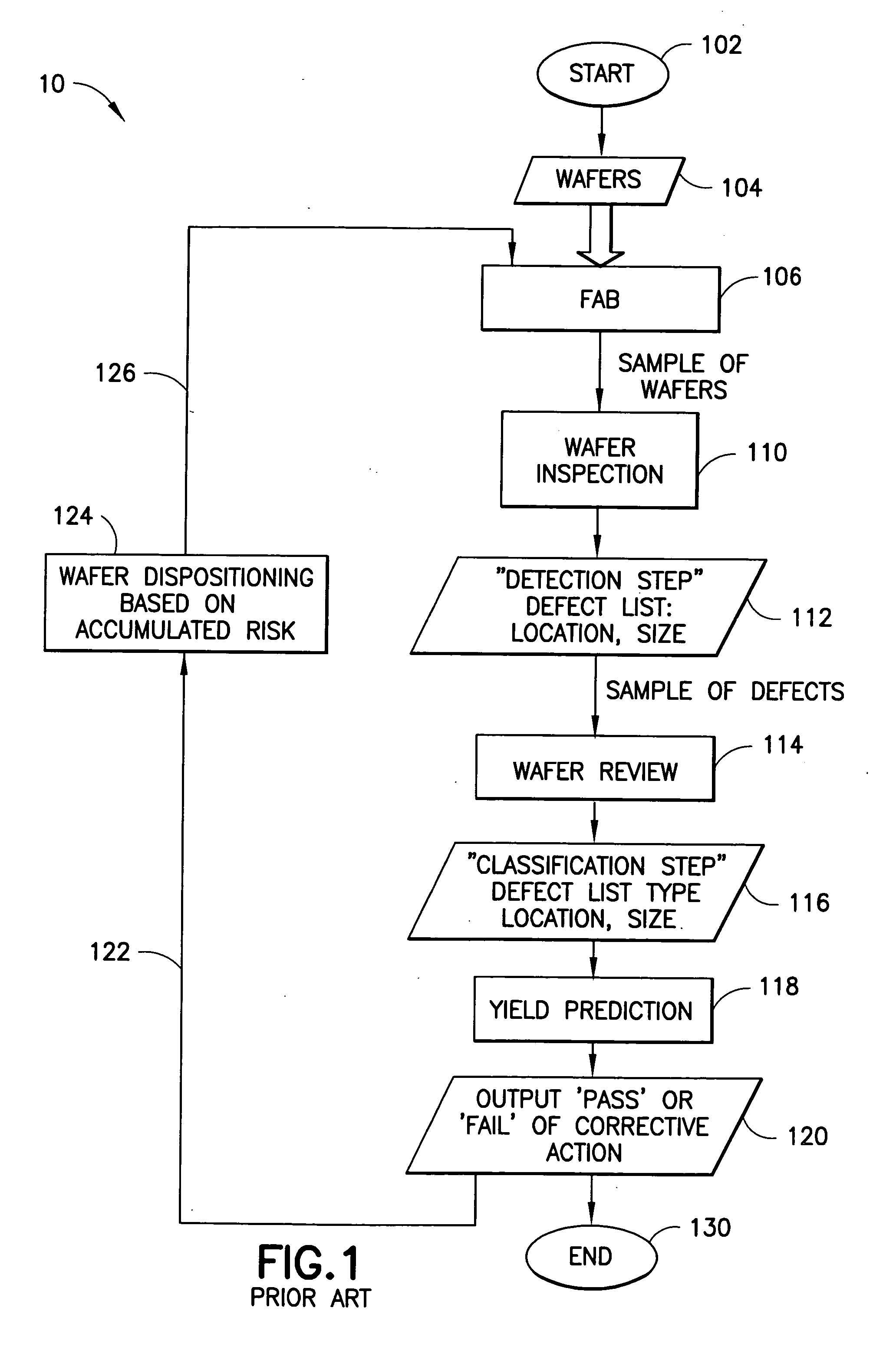

[0028] Semiconductor fabrication yield teams are continually challenged to increase yields. The lost revenue for each point of yield loss can be significant. In addition, the inspection process can be expensive and slow. Each tool has an associated Cost of Ownership (COO) which is driven by the capital cost of the tool and the tool's throughput. In order to increase yields there is a need to make better use of inspection resources. This can be accomplished by limiting the area inspected by high COO inspection tools, and by limiting the defects requiring review in high COO review tools.

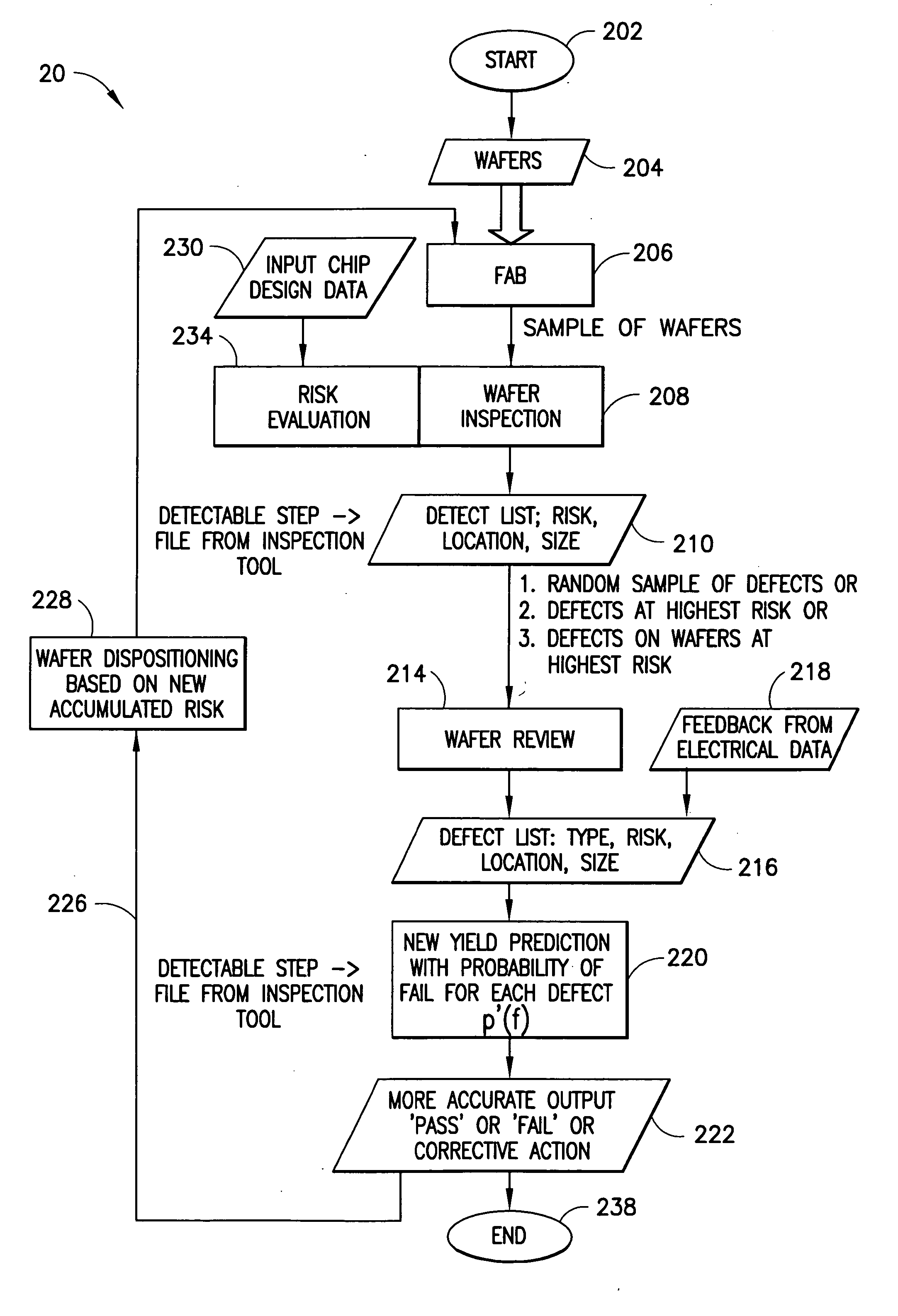

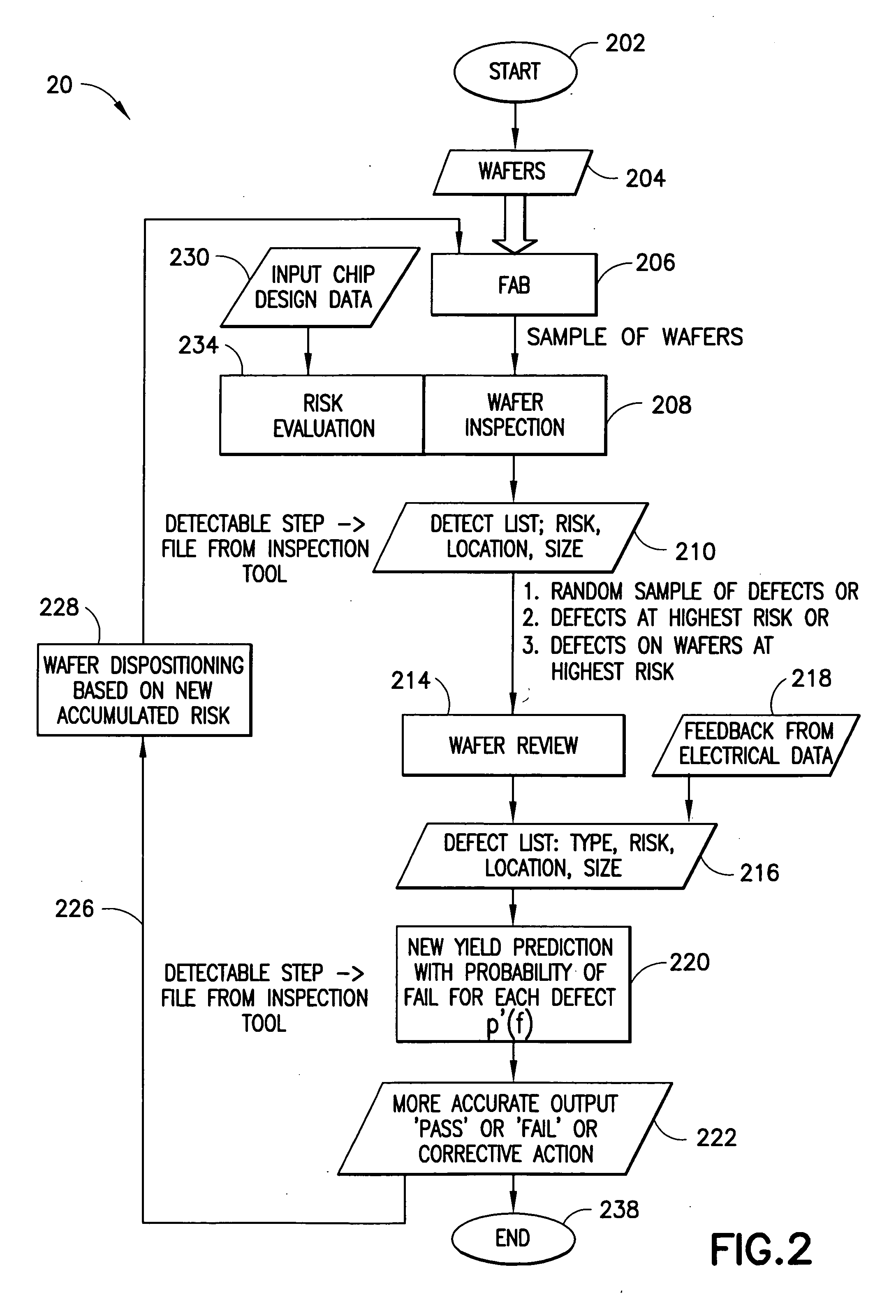

[0029] The present invention is an improved system and method for identifying catastrophic or killer defects in semiconductor wafers and / or circuits, and identifying at risk semiconductor wafers and / or circuits, i.e., those wafers and / or circuits that exhibit an enhanced risk of catastrophic failure or inoperability. The present invention also applies to multi-layer semiconductor wafer and / or circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com