Thermoacoustic Thermomagnetic Generator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

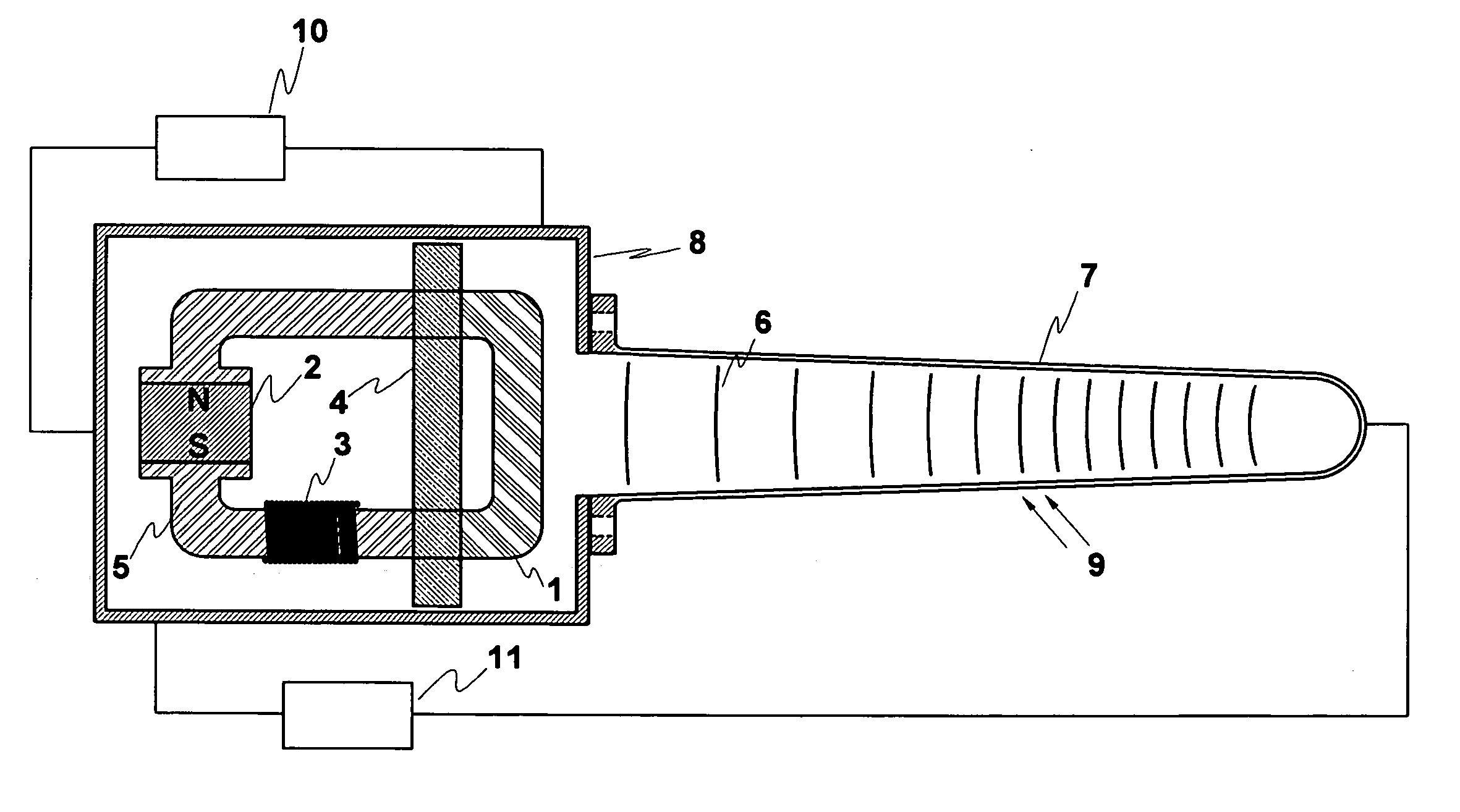

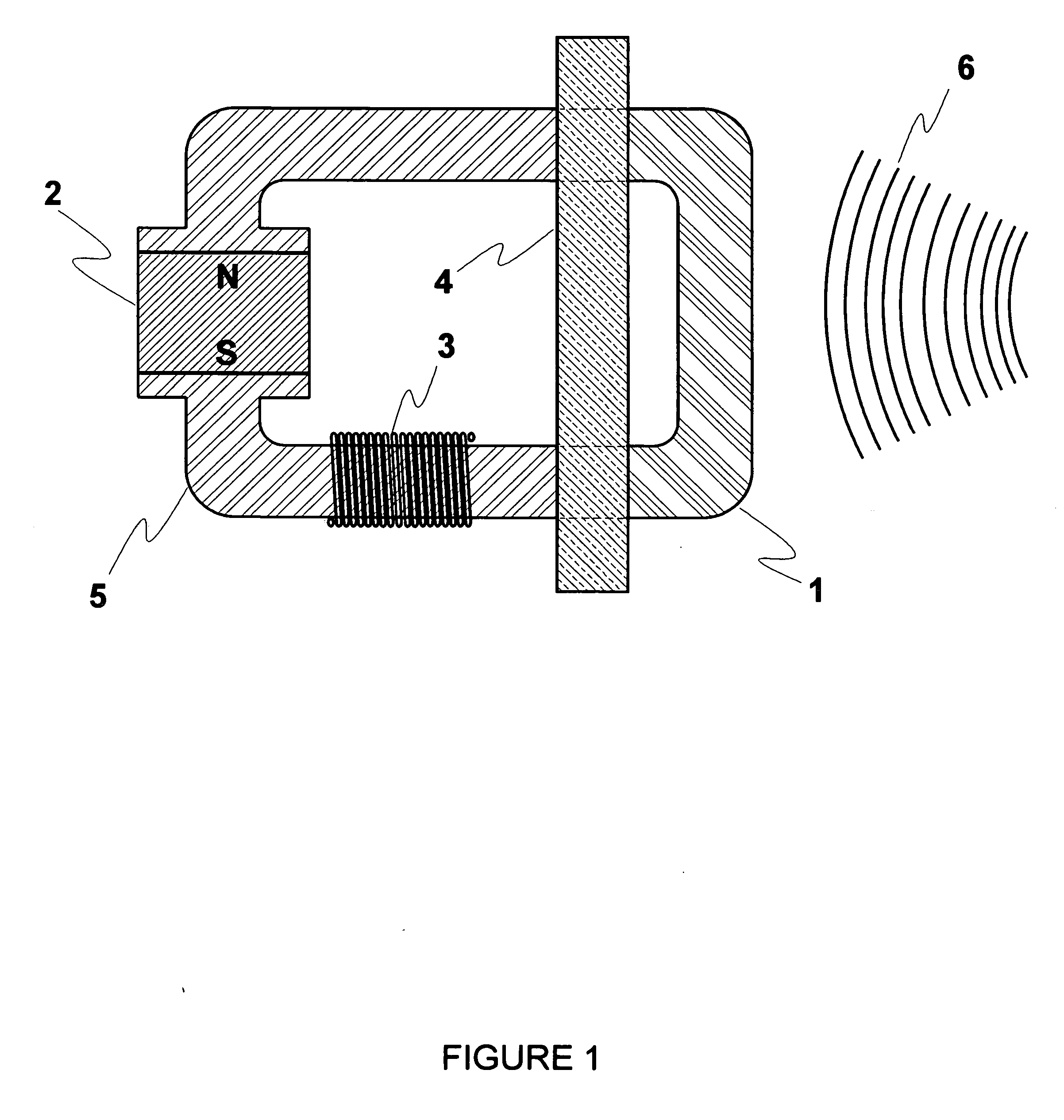

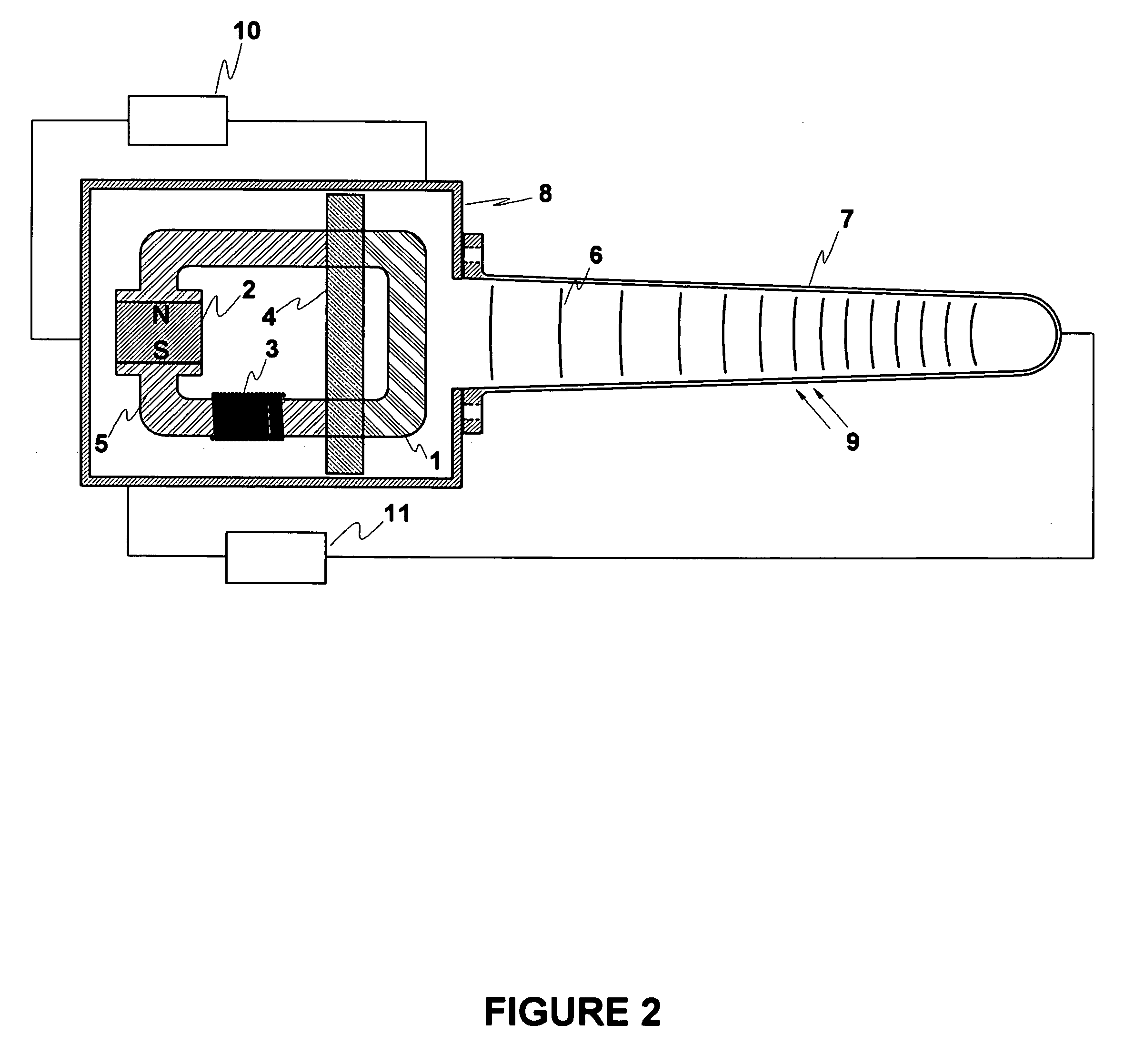

[0037] The Thermoacoustic Thermomagnetic Generator will be described with reference to drawings that are not to scale.

[0038] With reference to FIG. 1, the magnetic circuit opening and closing means 1 is in fixed contact with the stator means 5 and completes the magnetic circuit path with the poles of the magnetic field generating means 2. The thermal insulating means 4 is formed around the ends of the stator means 5 and the magnetic circuit opening and closing means 1 near where they are joined. The induction windings 3 are wound around the stator means pole piece. The thermoacoustic waves 6 impinge upon the magnetic circuit opening and closing means 1, periodically heating it past its Curie point and opening the magnetic circuit so that the magnetic field collapses and induces an electric current in the induction windings 3. The magnetic circuit opening and closing means 1 cools during the period between the thermoacoustic waves 6 and re-establishes the magnetic field. The expandi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com