Ink jet printing apparatus, ink jet print head, ink jet printing method, and method and program for setting print conditions

a printing apparatus and ink jet technology, applied in printing, other printing apparatus, etc., can solve the problems of low efficiency percentage, difficult machine, and inability to meet the requirements of printing, and achieve the effect of increasing the yield of the ink jet print head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

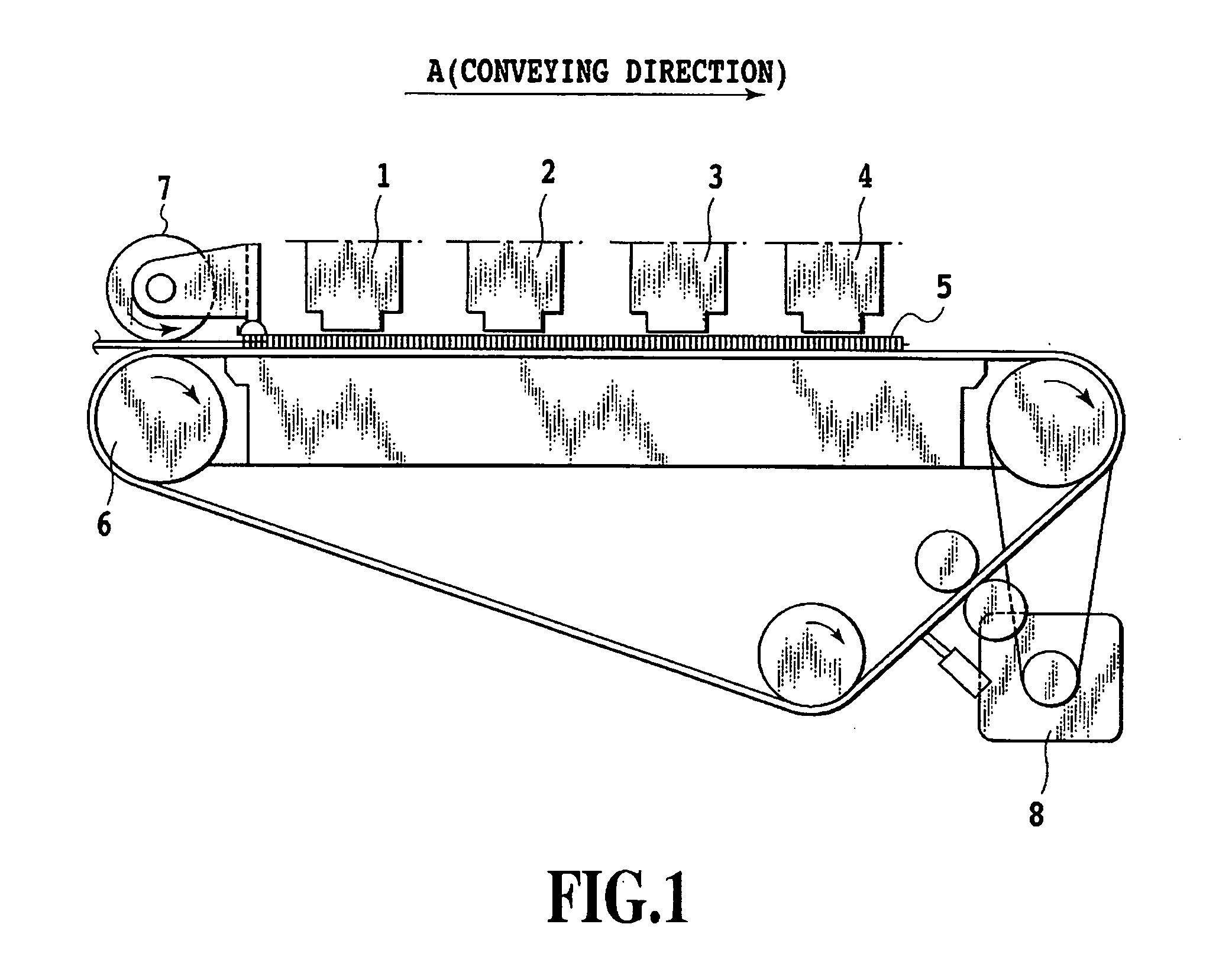

[0054]FIG. 1 is a side view illustrating the general configuration of an ink jet printing apparatus in accordance with a first embodiment of the present invention.

[0055] Long ink jet print heads 1, 2, 3, and 4 constitute a head unit. A plurality of ink ejection openings are arranged in each of the print heads to eject ink. The print heads 1, 2, 3, and 4 are long ink jet print heads that eject black (K), cyan (C), magenta (M), and yellow (Y) inks. Each of the print heads is supplied with ink through an ink supply tube (not shown). Moreover, control signals and the like are sent to each print head via a flexible cable (not shown). A print medium 5 such as ordinary paper, high-grade dedicated paper, an OHP sheet, glossy paper, a glossy film, or a postcard is sandwiched between a conveying roller 6 and a sheet pressing roller 7 and driven by a drive motor 8. The print medium 5 is thus fed in the direction of arrow A (conveying direction).

[0056] Liquid paths that are in communication w...

second embodiment

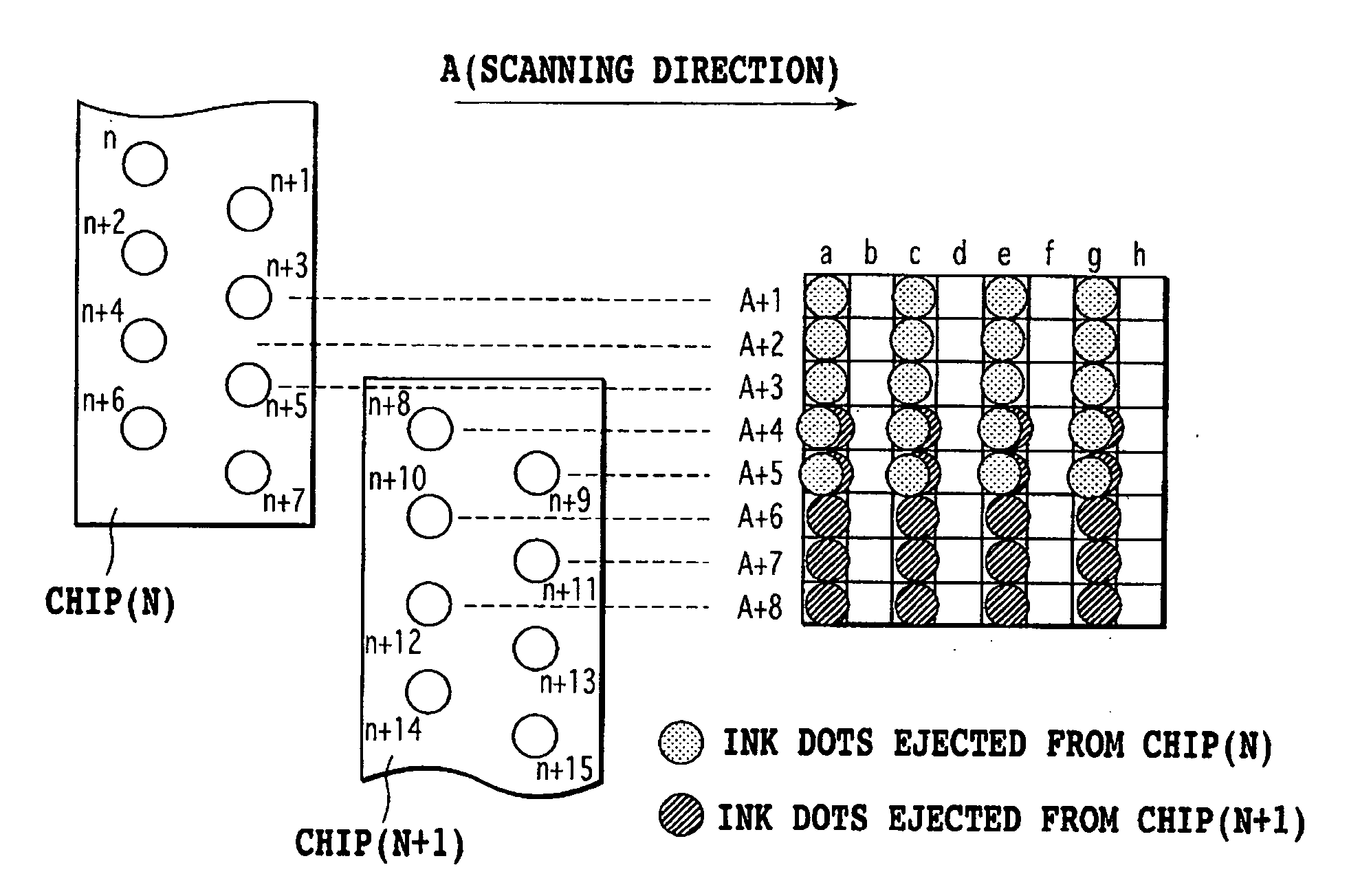

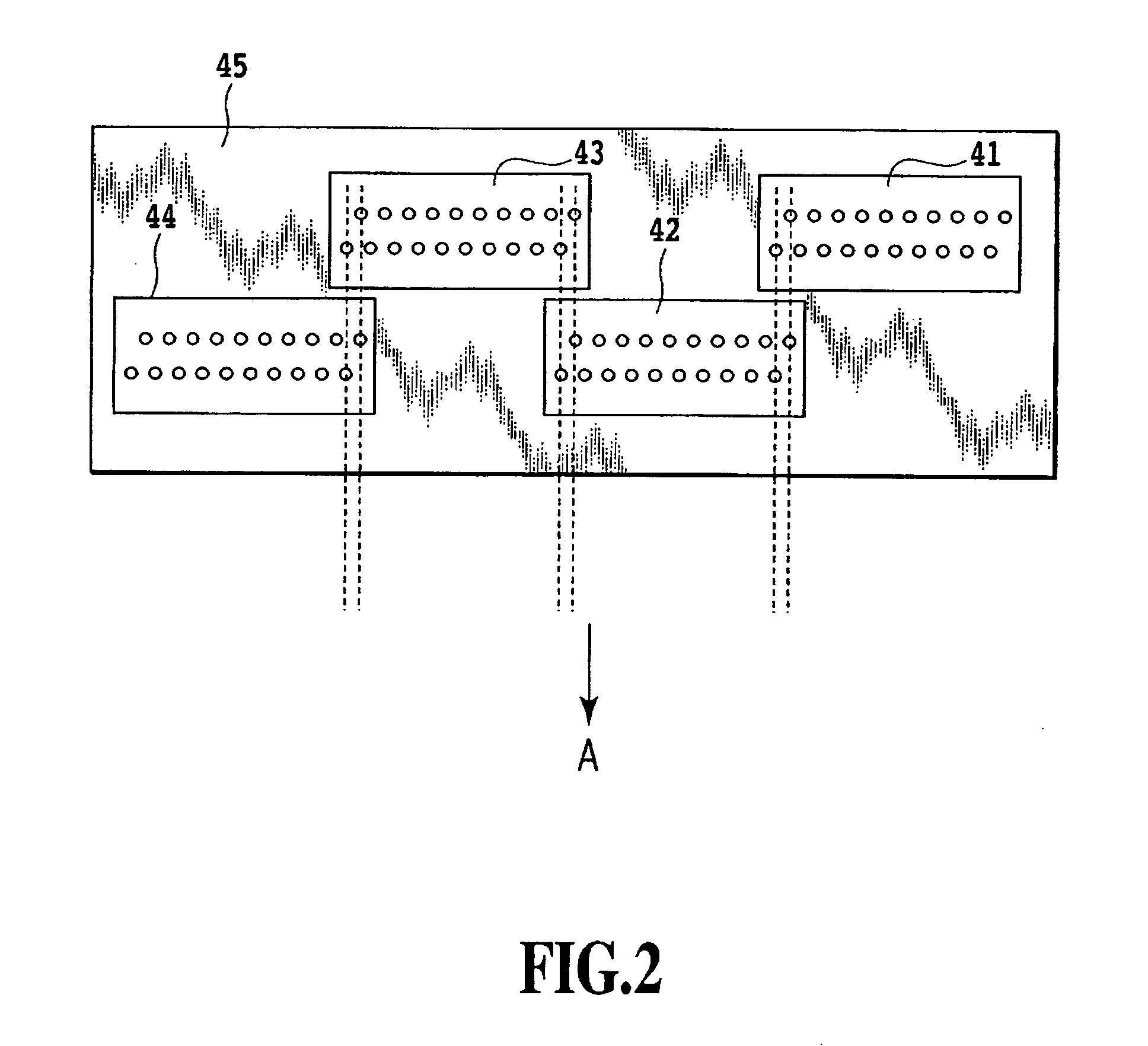

[0078]FIG. 13 shows an example of configuration of a full-multi type long print head used for a second embodiment of the present invention. In the present example, a print head includes a plurality of (in FIG. 13, four) short chips 51, 52, 53, and 54 each having four nozzle lines (L1, L2, L3, and L4). The chips 51, 52, 53, and 54 are staggered in the direction of the nozzle lines, thus constituting a long nozzle group unit 55. In each of the nozzle line groups L1 to L4, the pitch P between the nozzles is 600 dpi (about 42.4 μm). The nozzles in each of the nozzle line groups L1 to L4 are offset from the corresponding nozzles in the adjacent nozzle line group, by a P / 4 pitch (2,400 dpi). In each of the joining portions among the four chips 51 to 54, two nozzles in each of the nozzle line groups L1 to L4, that is, a total of eight nozzles in the nozzle line groups L1 to L4, overlap one another.

[0079] Alignment marks serving as reference positions are provided in the four corners of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com