Needle assembly with removable depth stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

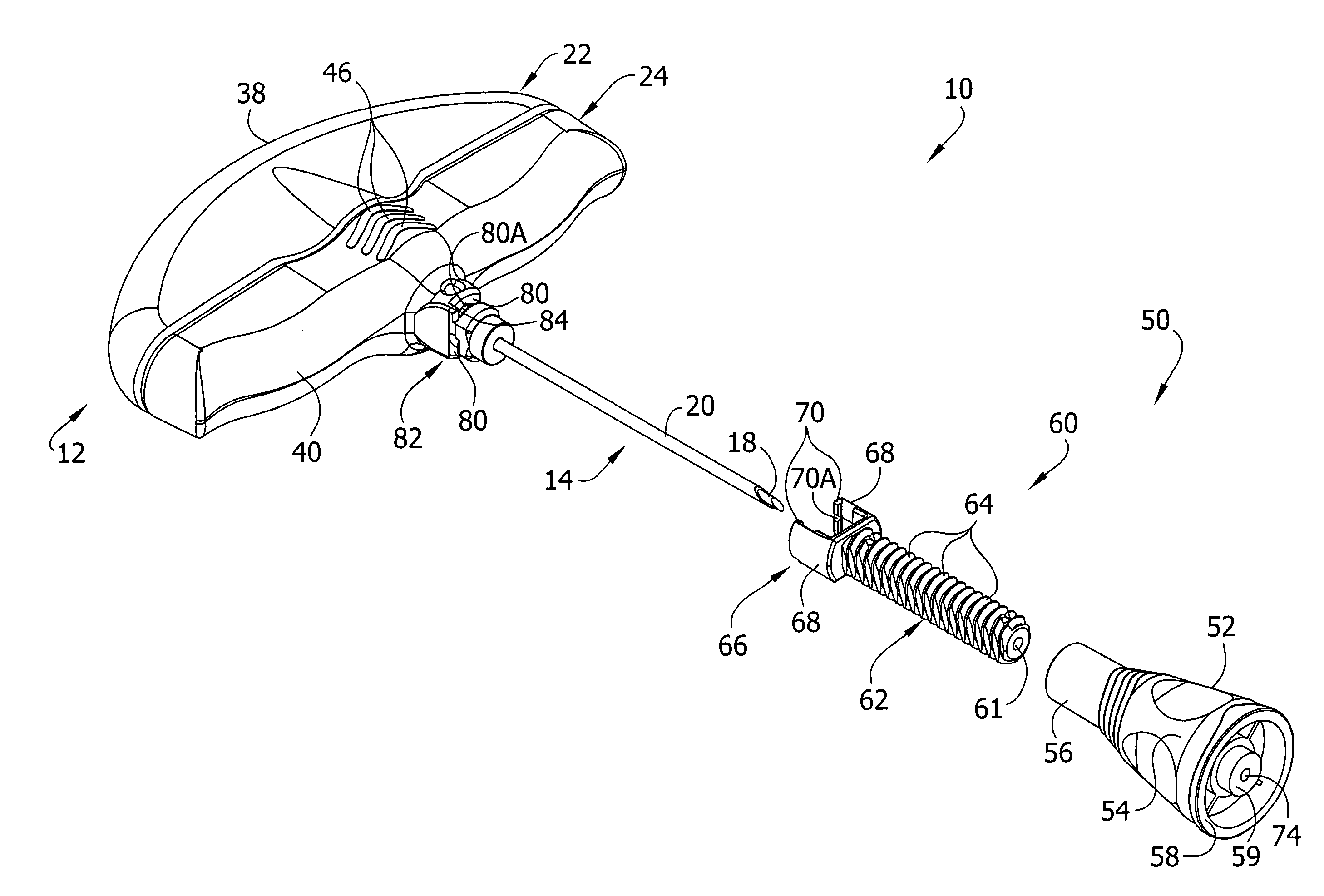

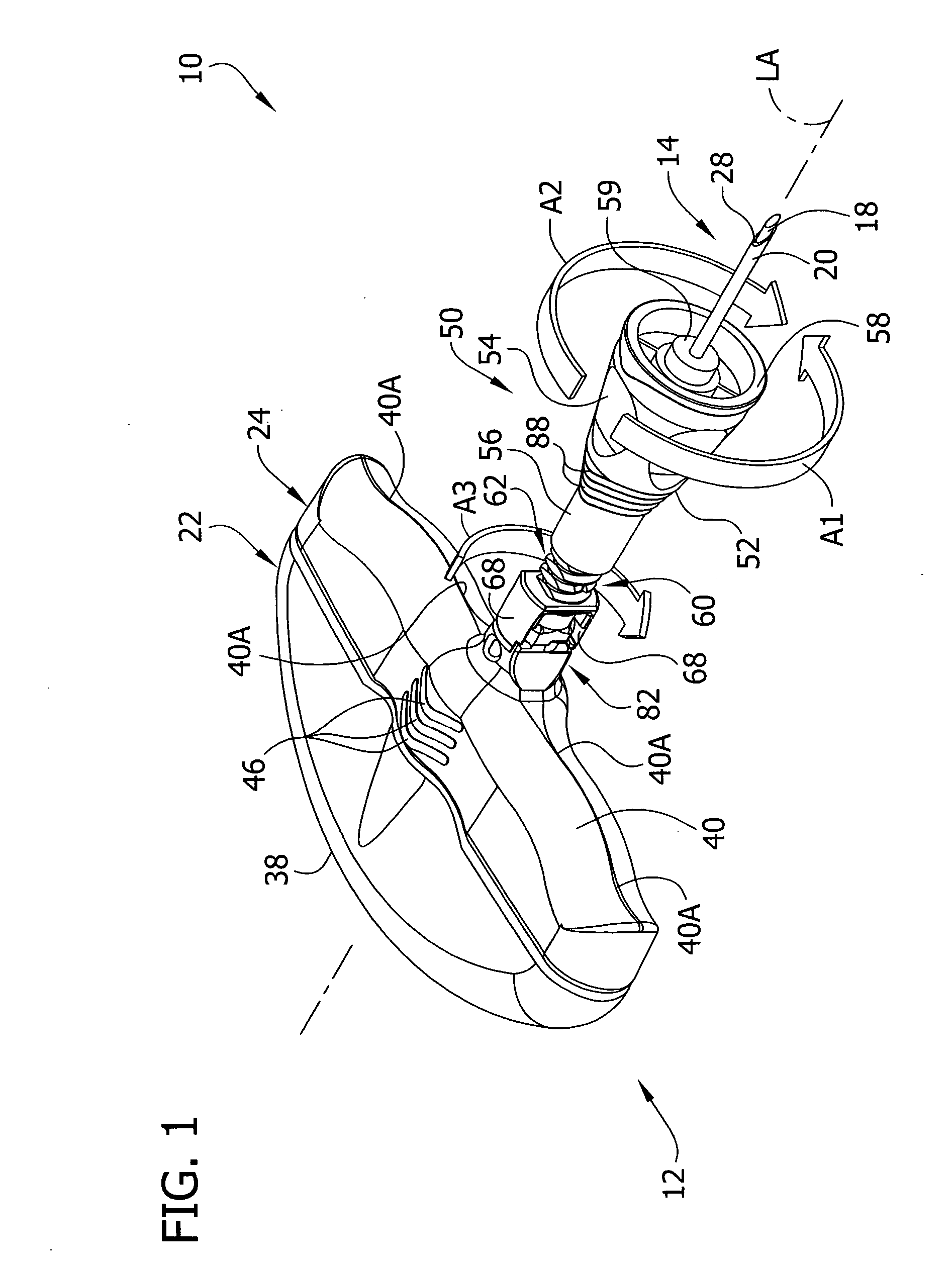

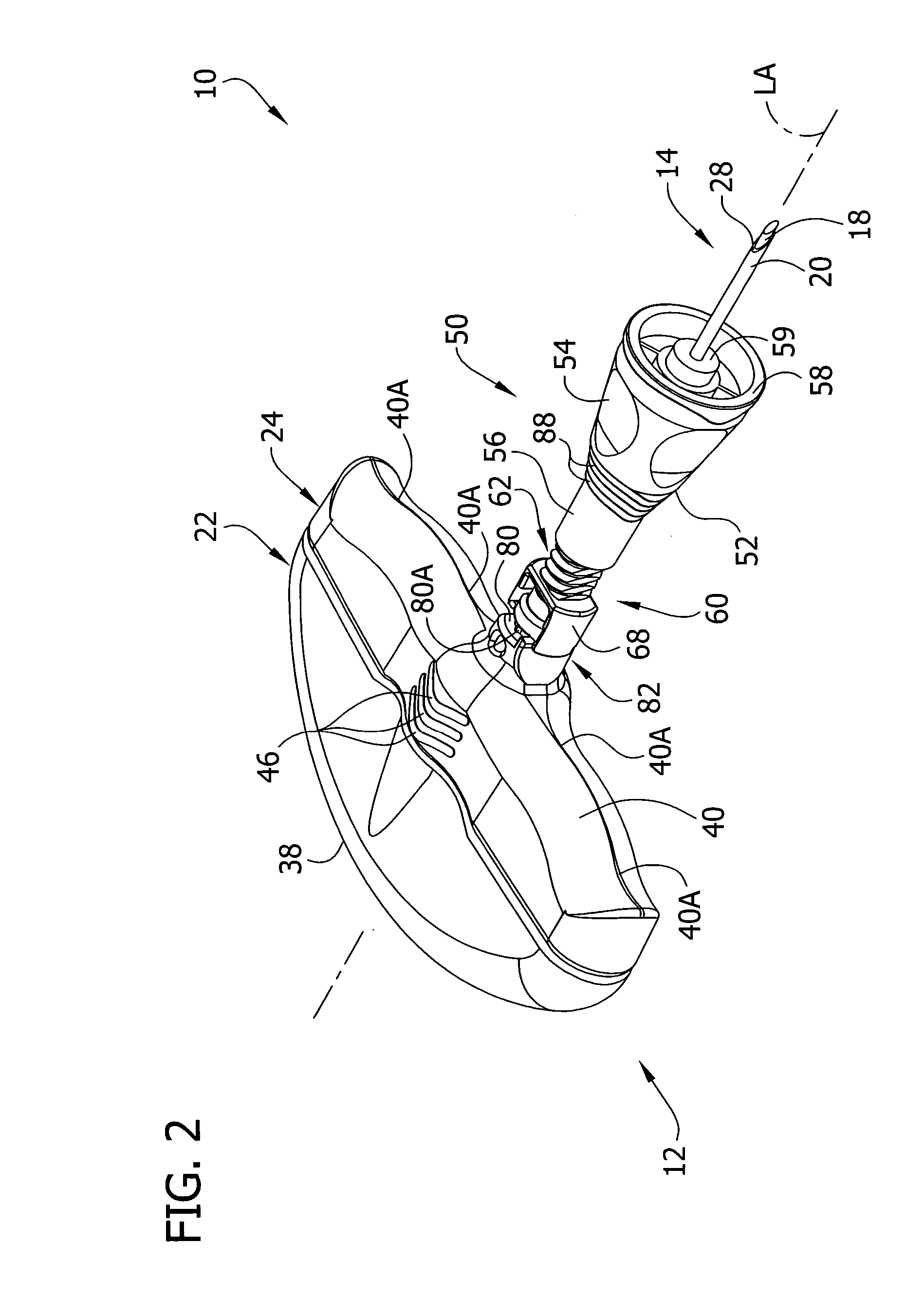

[0021] Referring now to the drawings and in particular to FIGS. 1-3, a bone needle assembly constructed according to the principles of the present invention is indicated generally at 10. The bone needle assembly includes a handle 12 (broadly, “mounting structure”), and a needle 14, all reference numbers indicating their subjects generally. The needle 14 includes a stylet 18 and a cannula 20 that can receive the stylet. The handle 12 includes a first or proximal handle member (indicated generally at 22) mounting the stylet 18, and a second or distal handle member (indicated generally at 24) mounting the cannula 20. “Proximal” and “distal” refer to the relative location of the handle members to a medical technician when the needle assembly is in use. The proximal handle member 22 is in contact with the palm of the technician's hand in use, and the distal handle member 24 is on the opposite side of the proximal handle member from the palm. It will be understood that a needle could incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com