Acoustical insulation for motor vehicles

a technology for motor vehicles and acoustic insulation, applied in the field of motor vehicles, can solve the problems of high sound transmission loss, increased fiber-foam layer thickness, and high transmission loss of barrier mats, and achieve the effect of reducing the audibility of common externally-originated noises and substantial cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

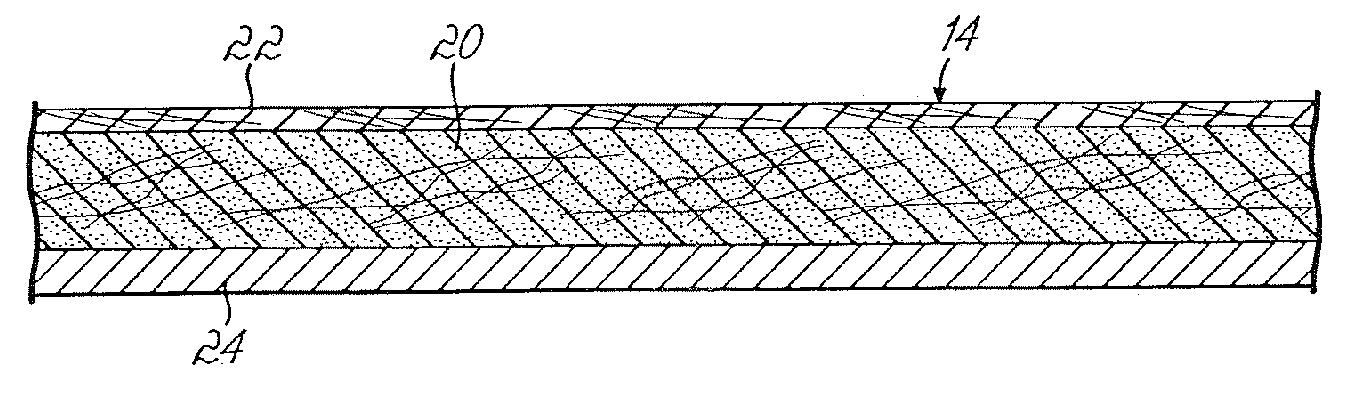

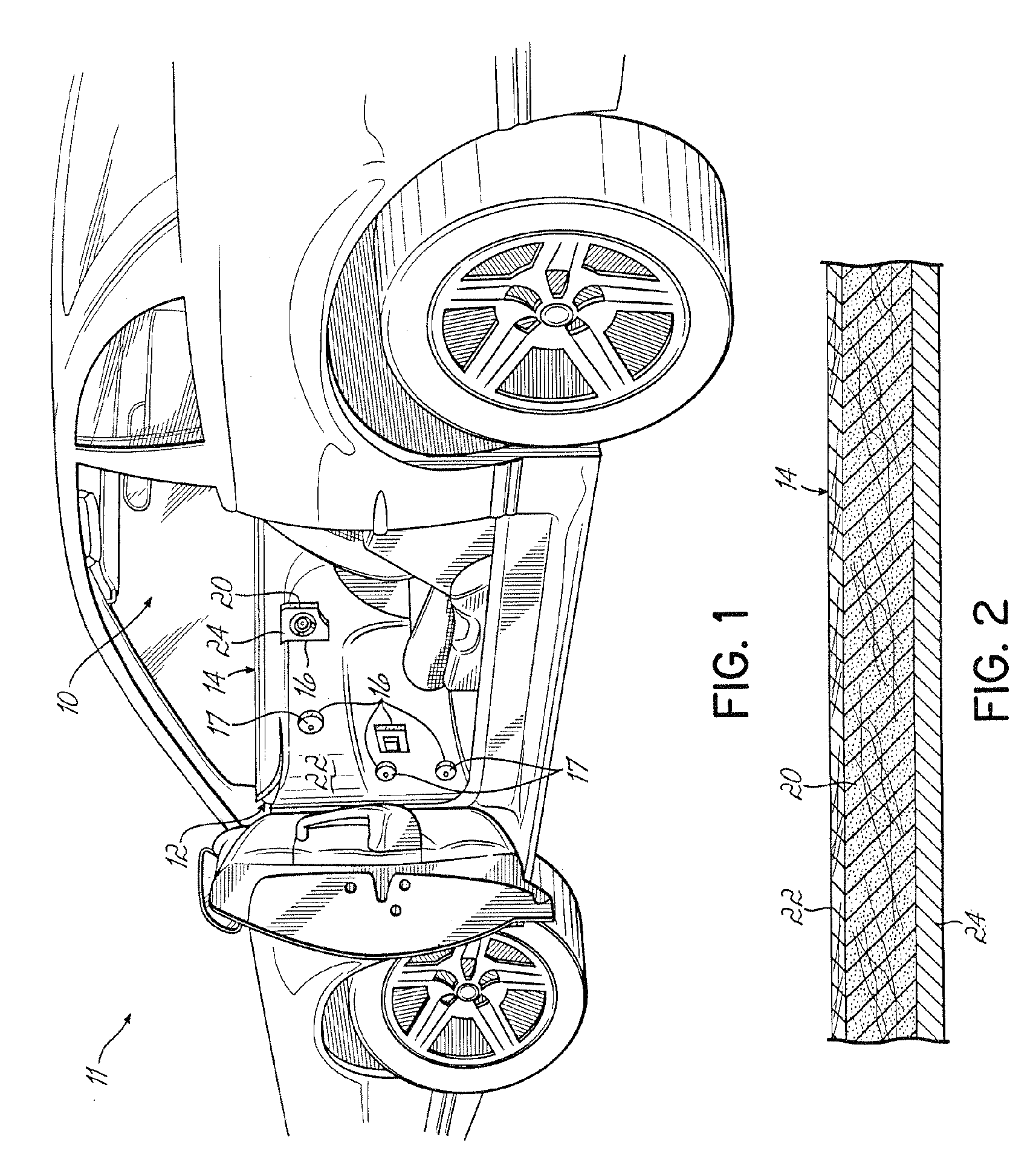

[0013] With reference to FIG. 1, a portion of a passenger cabin 10 of a motor vehicle 11 is shown with the instrument panel (not shown) removed to reveal the underlying firewall 12 separating the passenger compartment from the engine compartment. The firewall 12 is almost completely covered by an acoustical insulator 14. The acoustical insulator 14 may be attached to the firewall 12 with mechanical fasteners or by other attachment methods, such as adhesive, familiar to those skilled in the art. The acoustical insulator 14 functions by absorbing the sound that is transmitted though the firewall 12 and registered holes 16 and cutouts 17 and then reflected from the surface of the instrument panel onto the surface of the acoustical insulator 14.

[0014] There are various openings or cutouts 17 defined in the sheet metal 12 and registered holes 16 in the insulator 14 for the steering column, brake booster, pedals, cables, hoses, etc., which are commonly referred to by a person of ordinary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com