Device employing gas generating cell for facilitating controlled release of fluid into ambient environment

a gas generation cell and fluid technology, applied in the direction of gaseous substances, tobacco, diseases, etc., can solve the problems of affecting the shelf life of fluid delivery devices, and most known devices not designed for long shelf li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] While the present invention is capable of embodiment in many different forms, there is shown in the drawings, and will herein be described in detail, one or more specific embodiments with the understanding that the present disclosure is to be considered an exemplification of the principles of the invention and is not intended to limit the invention to these specific embodiments.

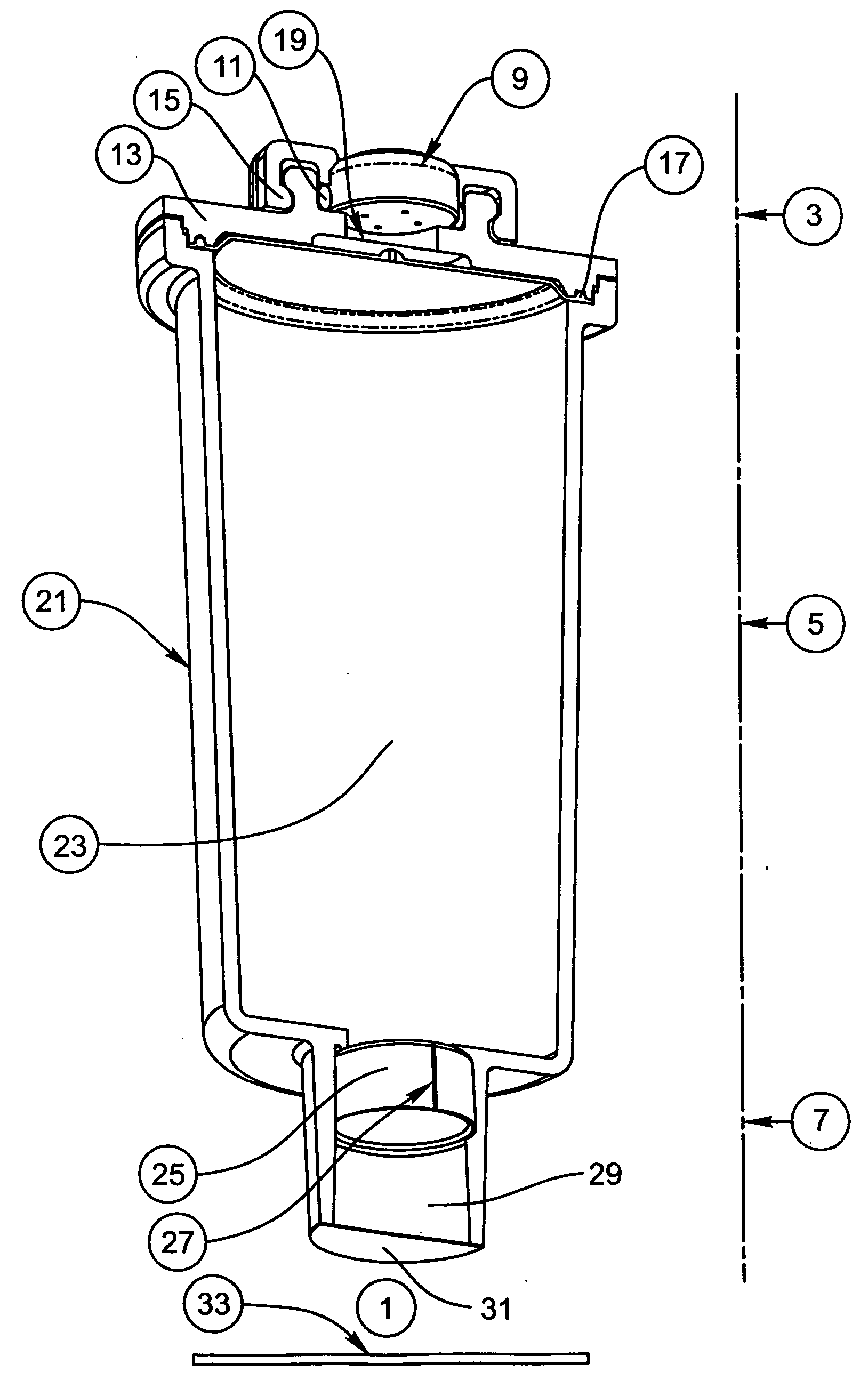

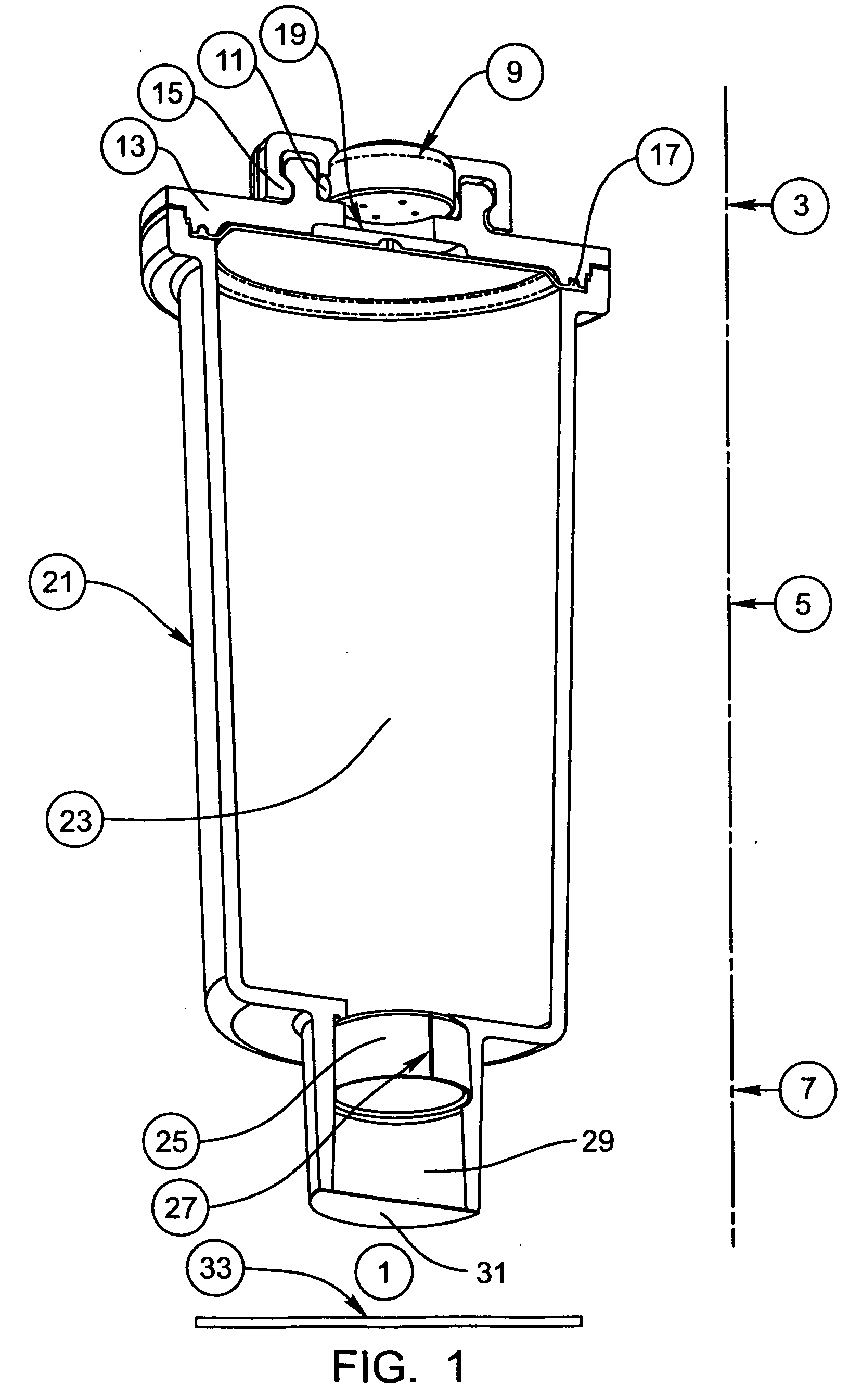

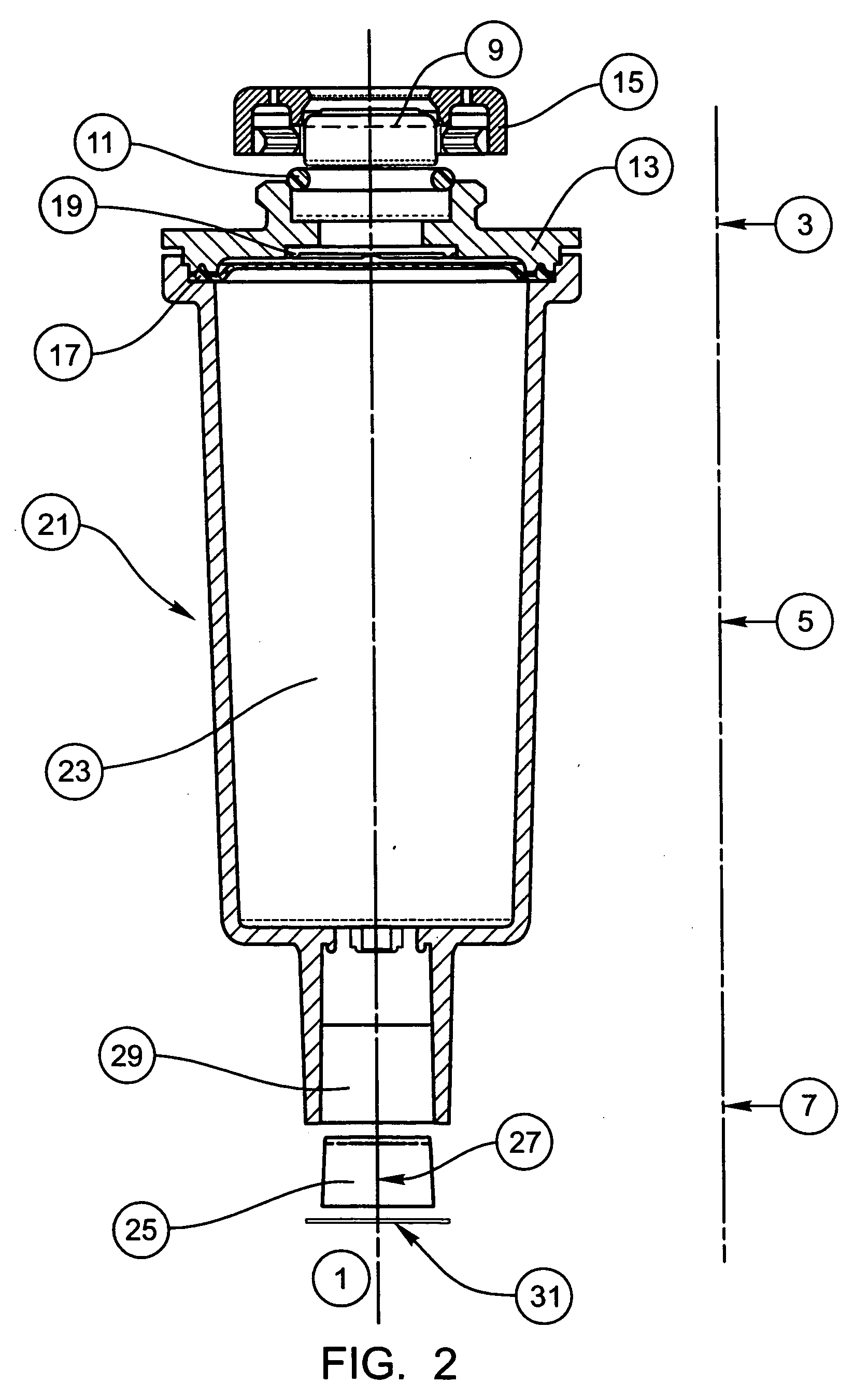

[0045]FIG. 1 depicts a particular embodiment of the device, shown in section view in order to illustrate the details of construction. FIG. 2 shows the preferred embodiment in an exploded section view. In this embodiment, the device has two main components, a fluid delivery container 1 and an emanation system 33. The container 1 is made up of three main sections, a gas generation compartment 3, a fluid compartment 5 and an orifice compartment 7.

[0046] The gas generation compartment 3 features a gas generating cell 9, held within a top cover 13. The top cover 13 is made of a material that is substantia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com