Methods for producing even wall down-hole power sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

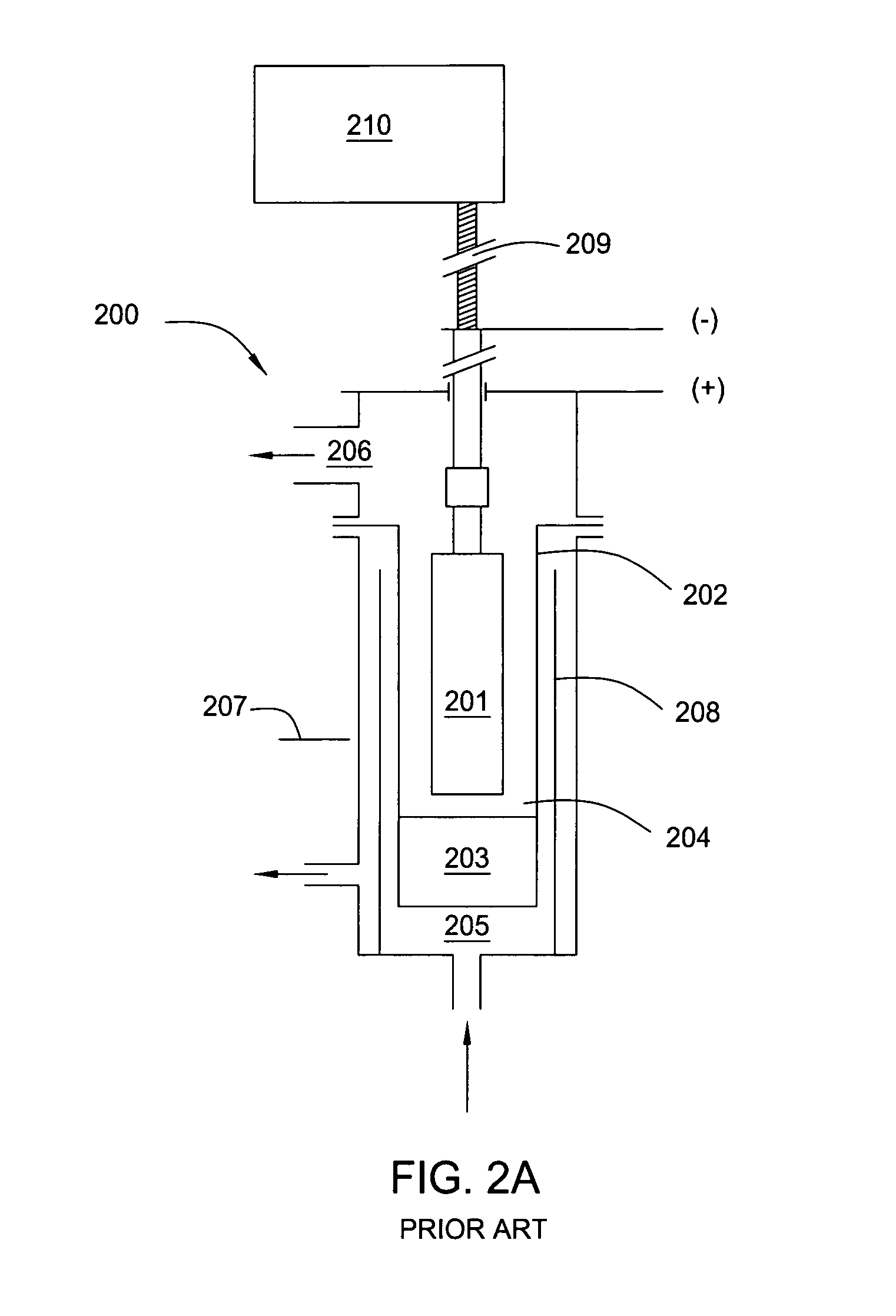

[0034] A simplified schematic of a vacuum arc remelting (VAR) process 200 is shown in FIG. 2A. A cylindrically shaped, alloy electrode 201 is loaded into a liquid-cooled, copper crucible or mold 202 of a VAR furnace, the furnace is evacuated, and a direct current (dc) electrical arc is struck between the electrode (cathode) and some start material (e.g., metal chips) at the bottom of the crucible (anode) 202. Alternatively, the electrode 201 may be continuously fed into the mold 202 and the mold may be made from graphite or another conductive material. Preferably, the electrode 201 is made from a metal, such as steel. The arc heats both the start material and the electrode tip, eventually melting both. As the electrode tip is melted away, molten metal drips off, forming a part 203 beneath while the electrode 201 is consumed. Because the crucible diameter is larger than the electrode diameter, the electrode must be translated downwards toward the anode pool to keep the mean distance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

| Vacuum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap