Paintball loading device

a technology of loading device and paintball, which is applied in the direction of launching weapon, white arms/cold weapons, weapons types, etc., can solve the problems of inability to completely eliminate jamming, and disadvantage of adding height profil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

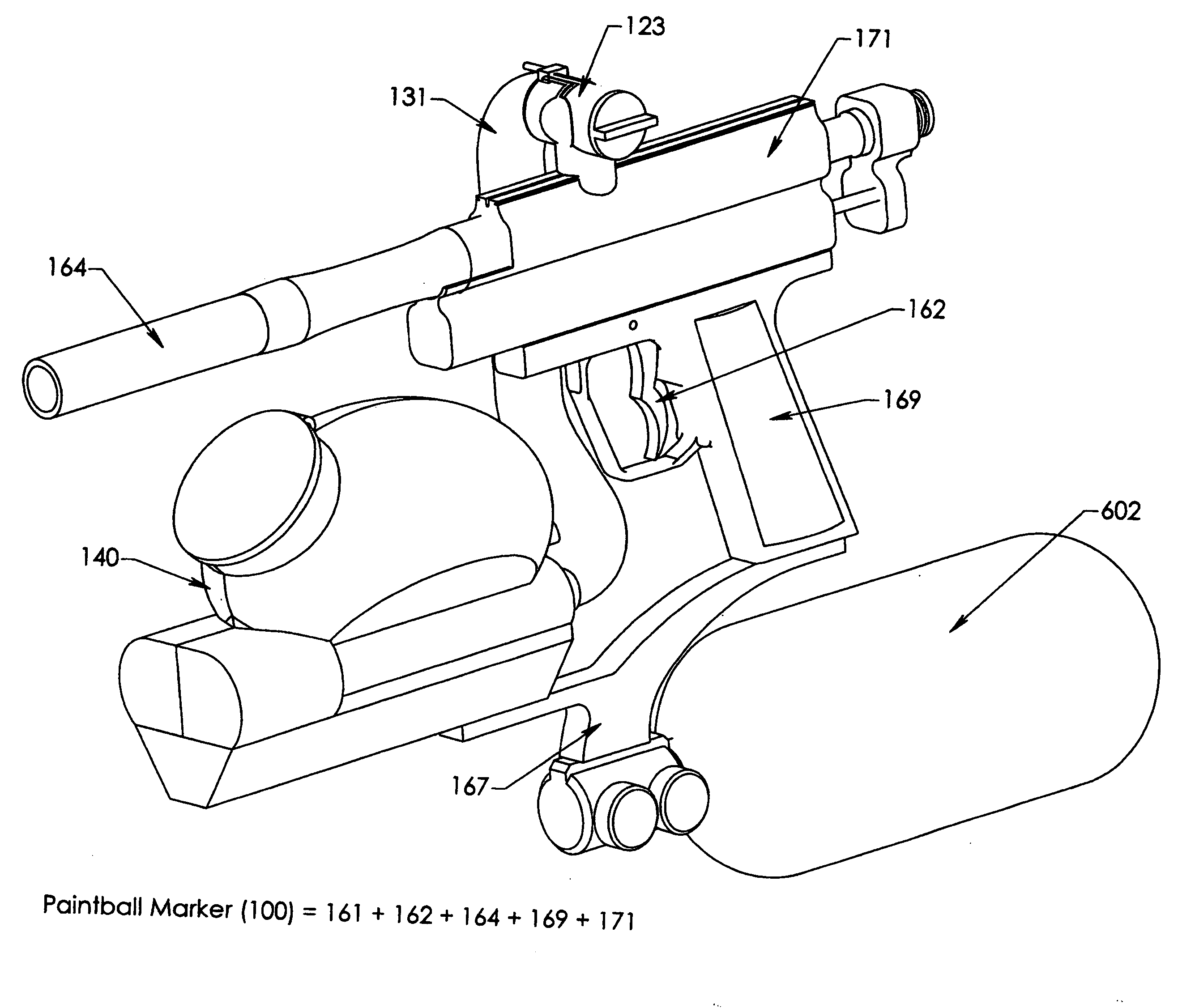

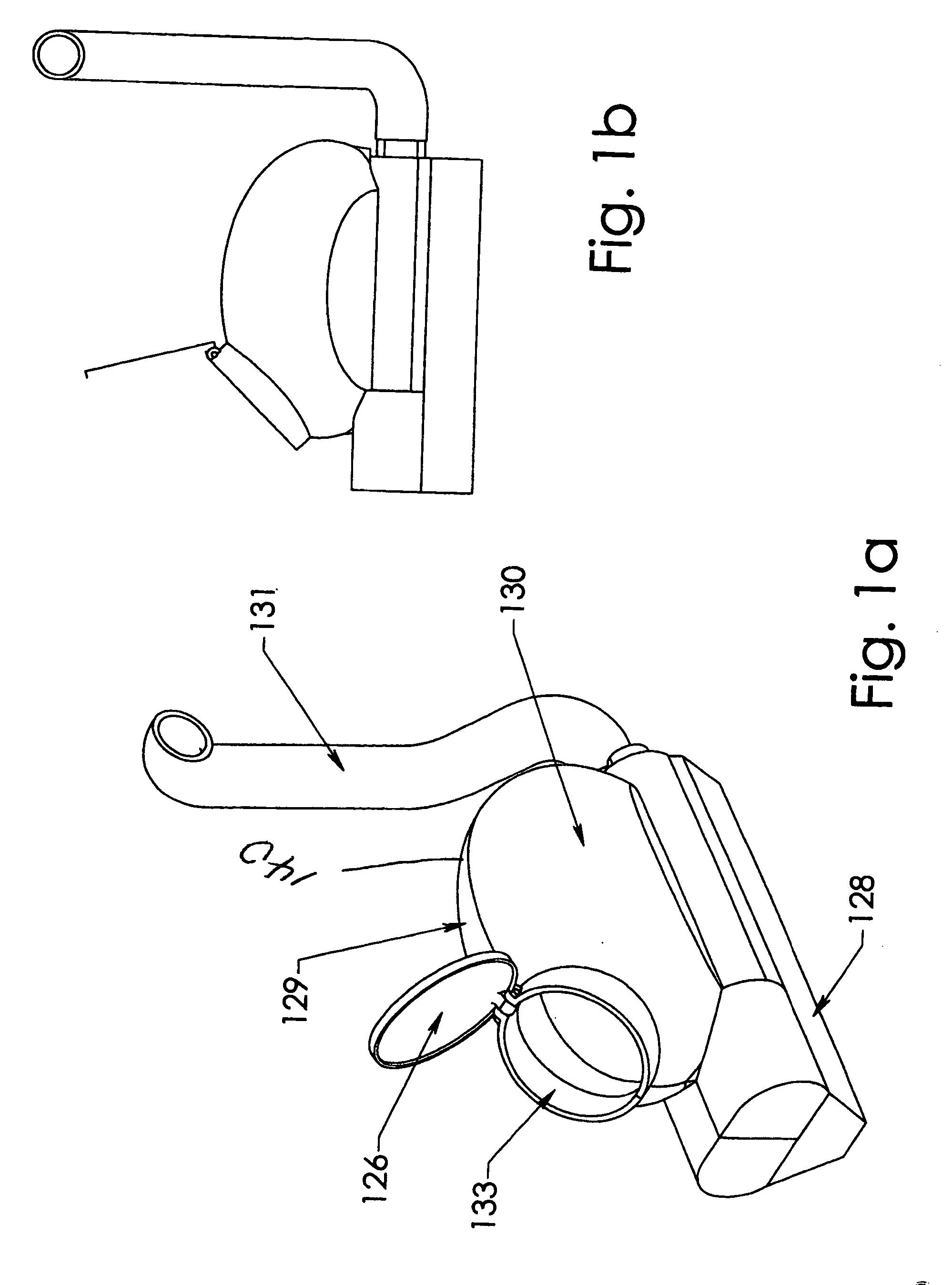

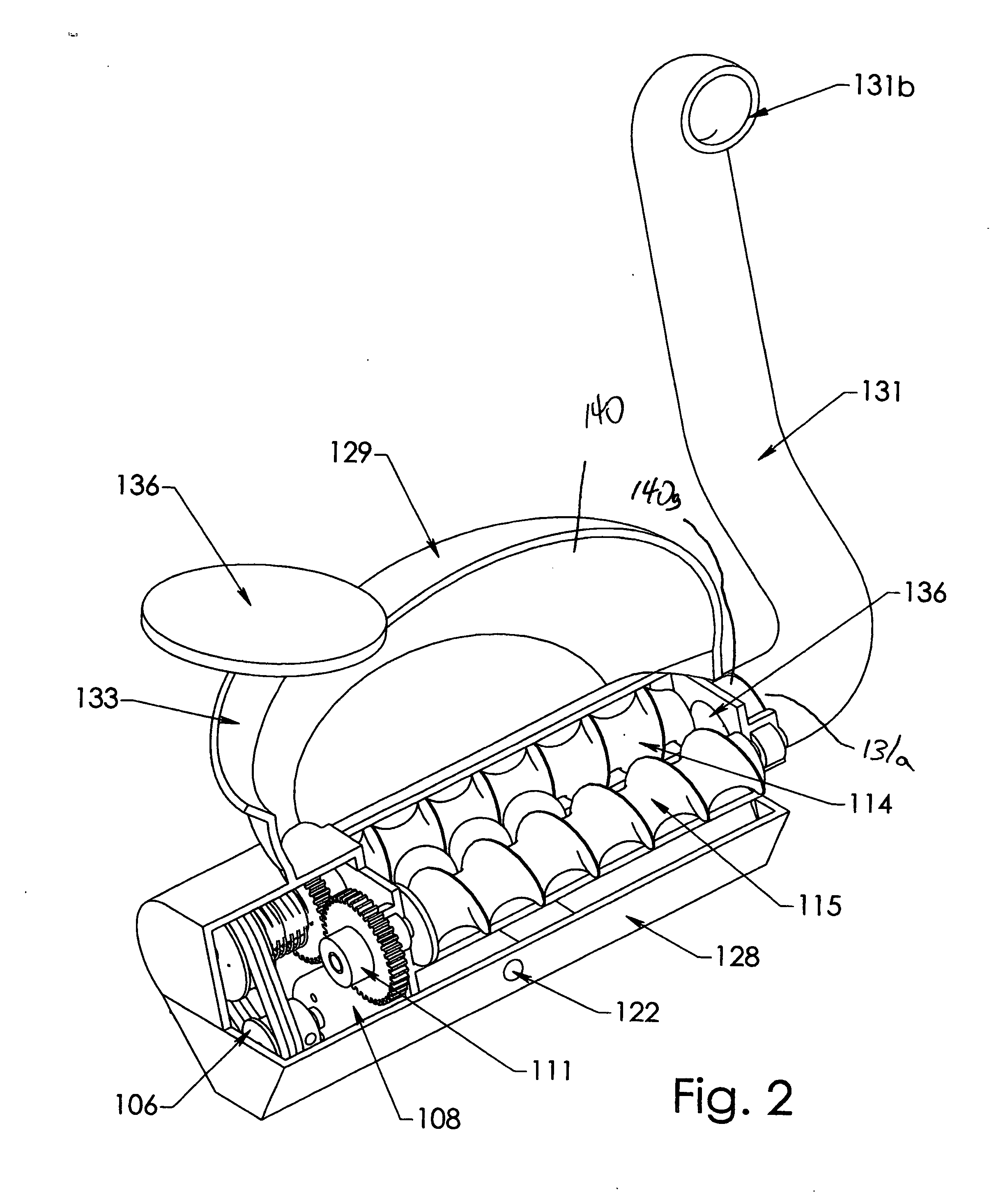

[0042] Referring firstly to FIG. 6 the present invention is an automatically fed paint ball marker, shown generally as item 11 which consists of a paintball marker 12 and an automatic paintball loading device 14. Paintball loading device 14 comprises a paintball hopper 16 having opening 18 and exit port 20. A drive housing 24 is mounted immediately below hopper 16. Drive housing 24 has an augur channel 26 containing a pair of parallel helical augurs 114 and 116 (see FIG. 9). Augur channel 26 has an exit port 136. Feed tube 131 has opposite ends 131a and 170a. End 131a is coupled to exit port 136 and end 170a is coupled to breech 170 of paintball marker 12. The augurs are coupled to drive mechanism 22. Drive mechanism 22 is configured to rotate the augurs in a counter rotating fashion in order to drive paintballs between the augurs and through feed tube 131 and into breach 170.

[0043] Drive mechanism 22 consists of an electric motor 108 coupled to pulley 106 which is in turn coupled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com