Tubular running apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

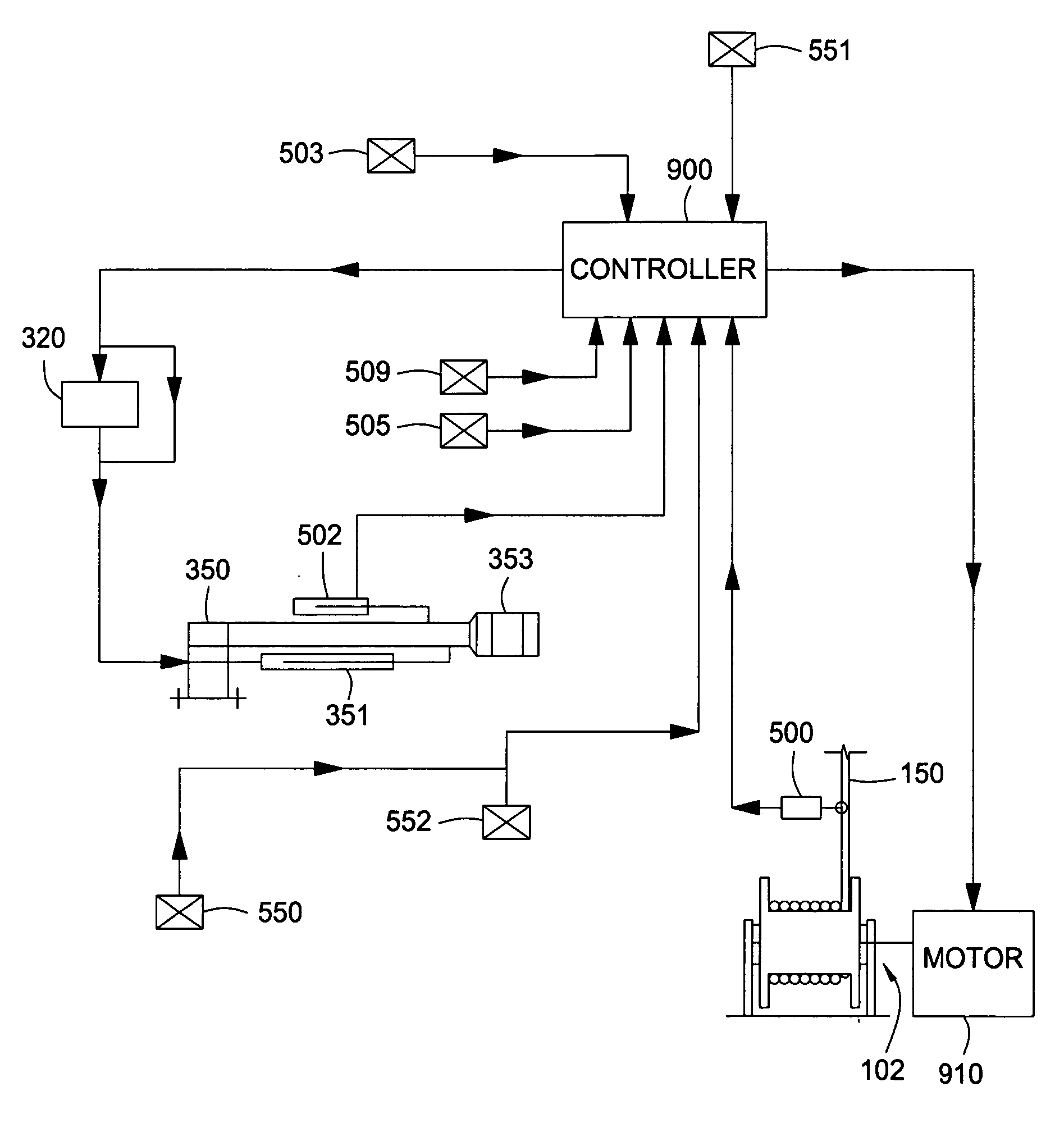

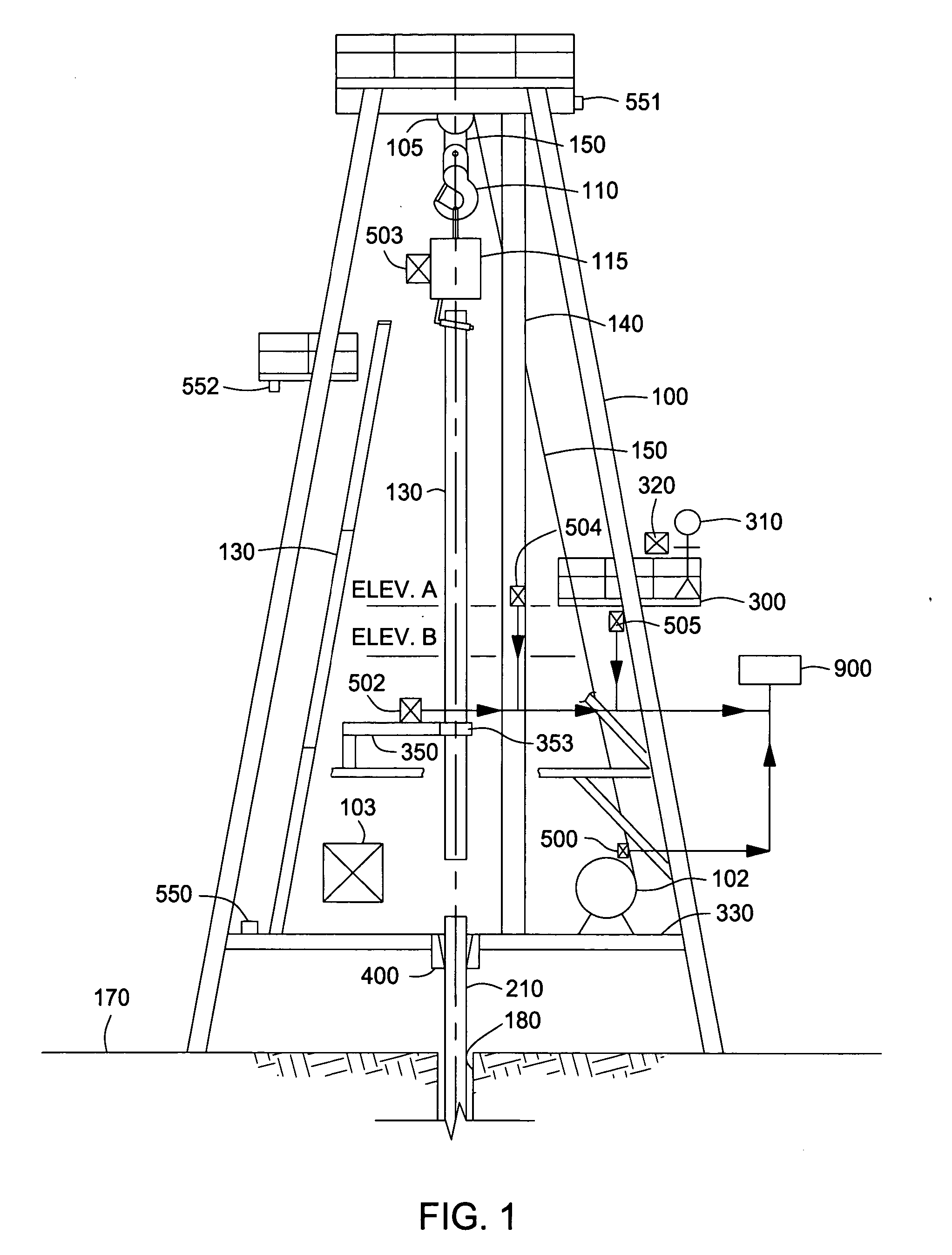

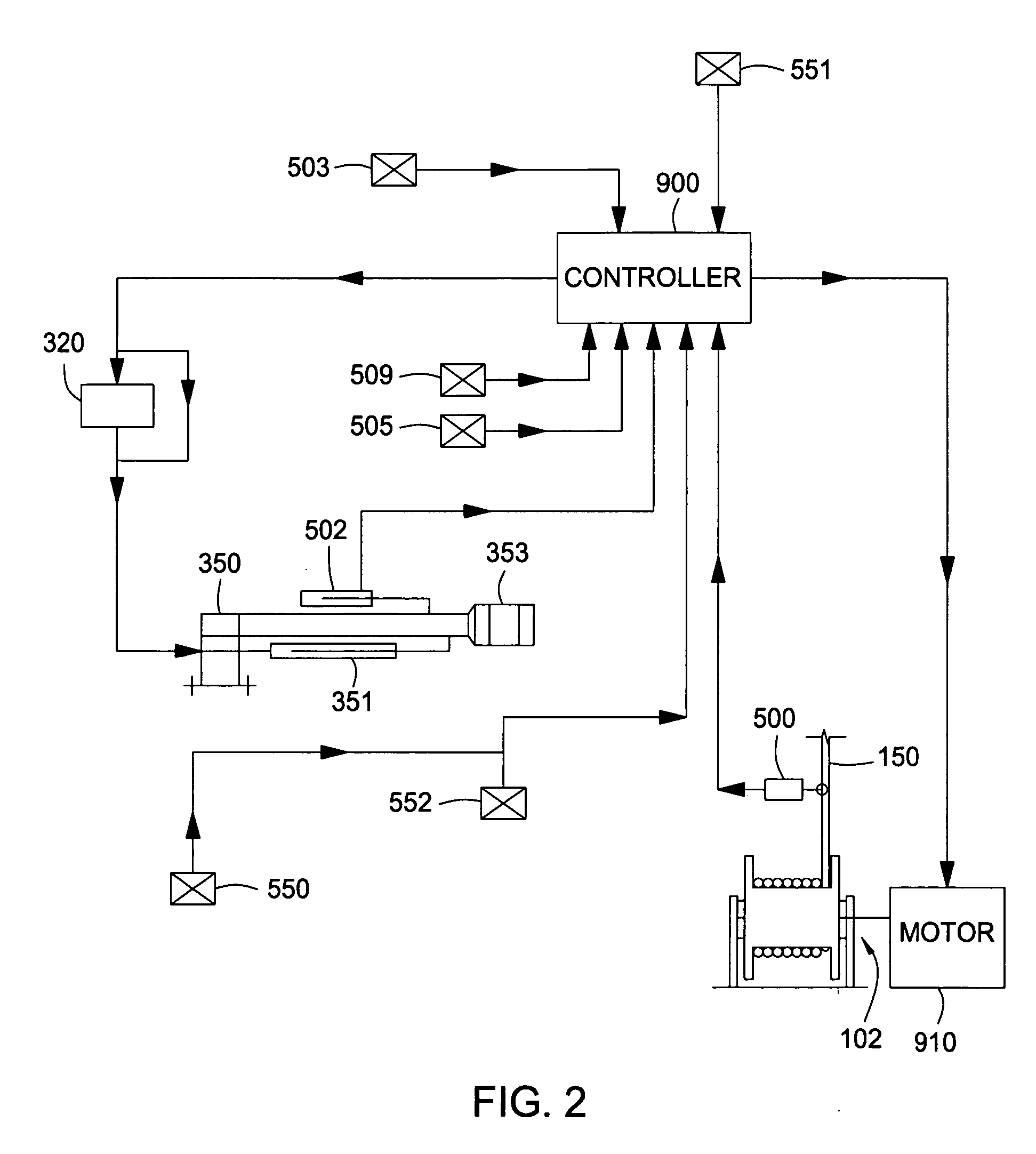

[0019] In one embodiment, a monitor system is provided for use with a drilling rig during assembly and disassembly of tubulars in the ground or subsea surface. The system may by utilized to prevent collisions of drilling rig power tools during tubular assembly and disassembly.

[0020]FIG. 1 illustrates a side view of a drilling rig 100 on a surface 170 above a wellbore 180. The drilling rig 100 includes a draw-works 102 with a cable 150 attached to a pulley system 105, for raising and lowering a hoisting system 115. The hoisting system 115 is shown schematically and could include any type of hoisting system, such that disclosed in U.S. Pat. No. 6,742,596 and U.S. Patent Serial Number 2004 / 0003490 assigned to Weatherford / Lamb, Inc., and herein incorporated by reference in their entirety. The drilling rig 100 further includes a platform 300 with an operator 310 and a control panel 320 to operate one or more tools 350. The platform 300 and operator 310 are located anywhere on the drilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com