Bulk material cargo container liner with internal restraint system for preventing the outward bulging of the liner

a technology for bulk material cargo containers and liner liners, which is applied in the direction of roofs, transportation and packaging, packaging, etc., can solve the problems of increasing the gross weight of the gross weight of the gross weight, complex structural systems, and time-consuming installation, so as to prevent the effect of movement or collaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

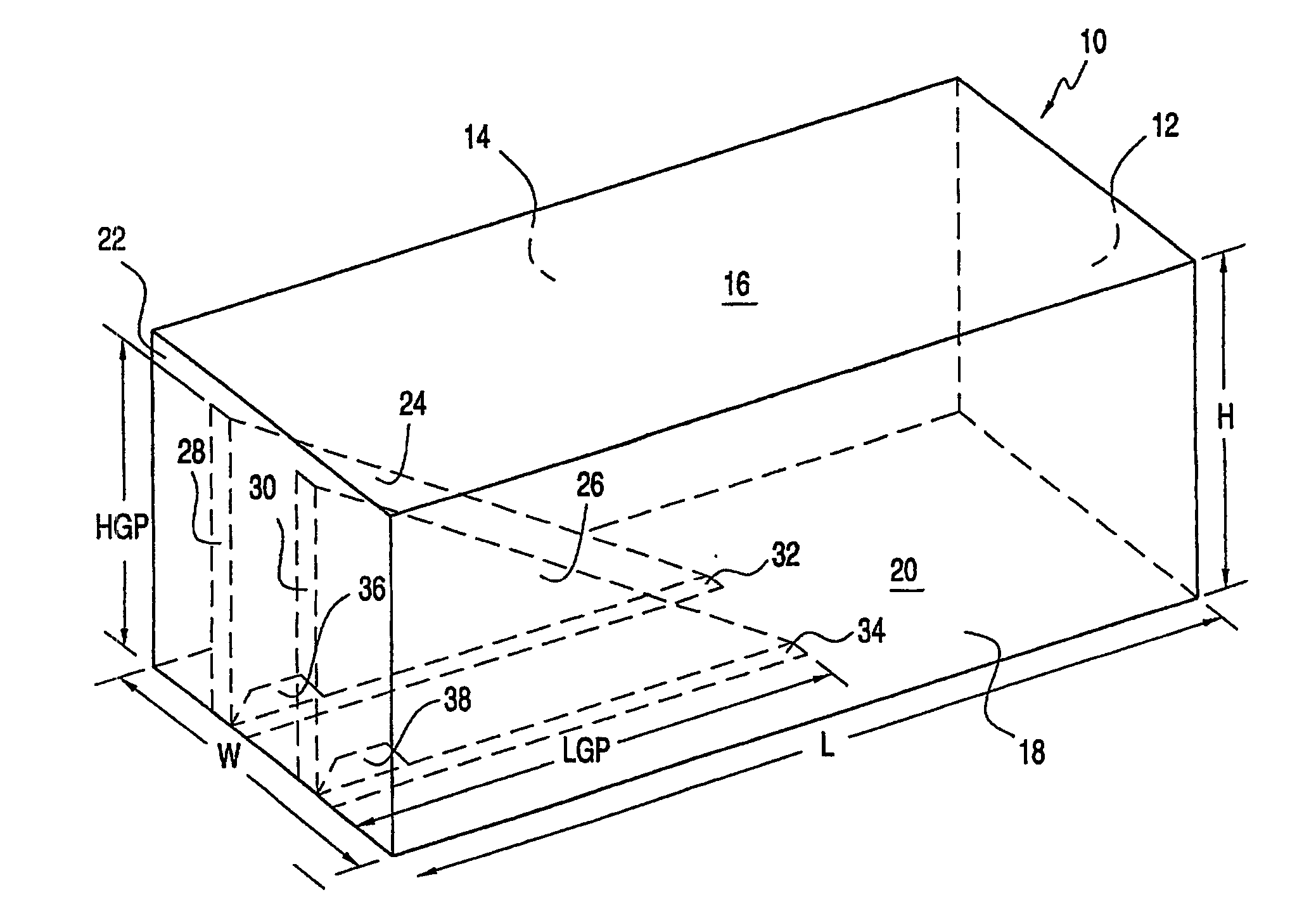

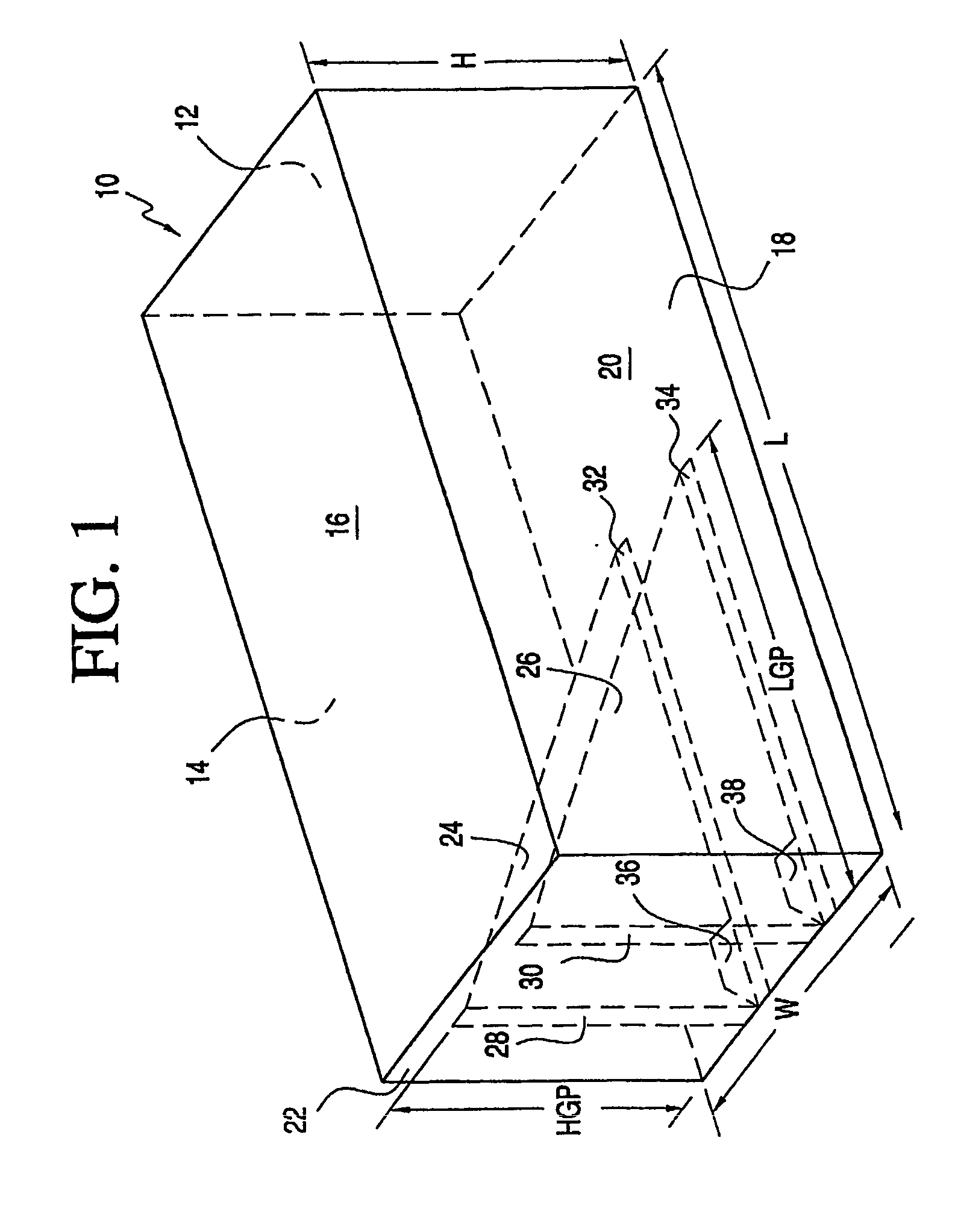

[0020] Referring now to the, drawings, and more particularly to FIG. 1 thereof, a new and improved bulk material cargo container liner, which is constructed in accordance with the teachings and principles of the present invention and which is adapted for use within bulk material cargo containers for holding and transporting bulk cargo materials, is illustrated and is generally indicated by the reference character 10. More particularly, the new and improved bulk material cargo container liner 10 of the present invention is preferably fabricated from a suitable material, such as, for example, extruded polyethylene, and as can readily be appreciated from FIG. 1, the bulk material cargo container liner 10 has a geometrical configuration which substantially comprises that of a rectangular parallelepiped. Accordingly, the bulk material cargo container liner 10 is seen to include, as viewed in FIG. 1, a front or forward wall member 12, a left side wall member 14, a top or ceiling member 16...

second embodiment

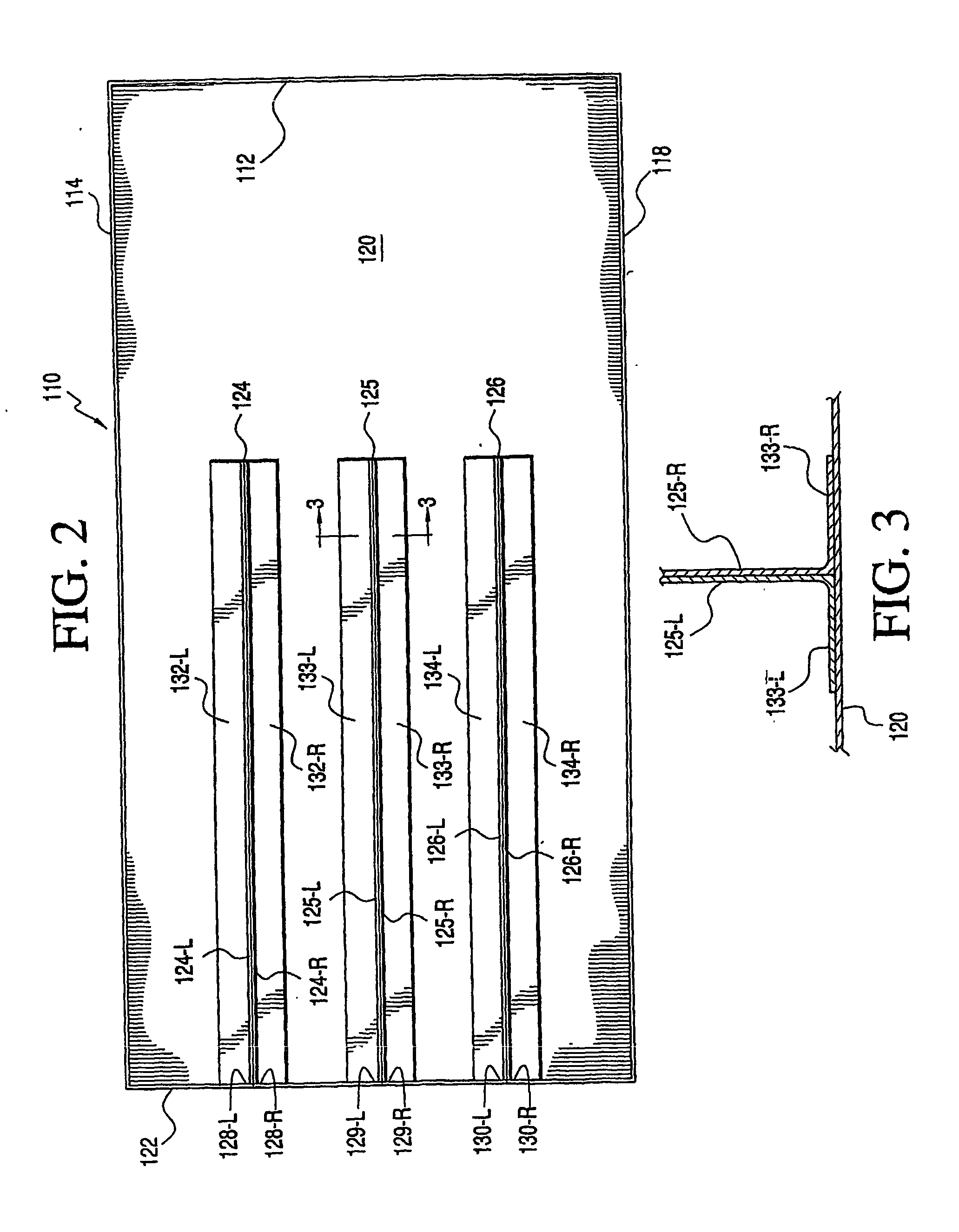

[0030] With reference now being made to FIG. 2, a new and improved bulk material cargo container liner, constructed in accordance with additional teachings and principles of the present invention, and which is likewise adapted for use within bulk material cargo containers for holding and transporting bulk cargo materials, is illustrated and is generally indicated by the reference character 110. It is to be noted that the bulk material cargo container liner 110, as disclosed-within FIG. 2, is substantially the same as the bulk material cargo container liner 10 as disclosed within FIG. 1, except as will be noted shortly hereinafter, and therefore, a detailed description of the bulk material cargo container liner 110 will be omitted herefrom for brevity purposes, the description of the bulk material cargo container liner 110 being confined to those structural features incorporated within the bulk material cargo container liner 110 which are different from, or are in addition to, those ...

fifth embodiment

[0044] Referring now to FIG. 6, a bulk material cargo container liner, generally indicated by the reference character 510, is illustrated wherein additional reinforcing straps are fixedly secured to exterior surface portions of the rear wall member 522 of the bulk material cargo container liner 510 so as to not only supplement or reinforce the internal gusset plate members, but in addition, to effectively connect the bulk material cargo container liner 510 to interior portions of the bulk material cargo container so as to effectively prevent any substantial movement of the bulk material cargo container liner 510 within or relative to the bulk material cargo container, as well as to effectively prevent the vertical collapse of the bulk material cargo container liner 510, when the bulk material cargo container is tilted during bulk material cargo load unloading operations. More particularly, it is seen that the bulk material cargo container liner 510 comprises a left side wall member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com