Machine for filling and sealing two-part capsules

a machine and capsule technology, applied in the direction of liquid materials, transportation and packaging, packaging goods types, etc., can solve the problems of major effort and expense in assembly of guide flaps, and the capsules that are free of defects can remain stuck on the good sid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

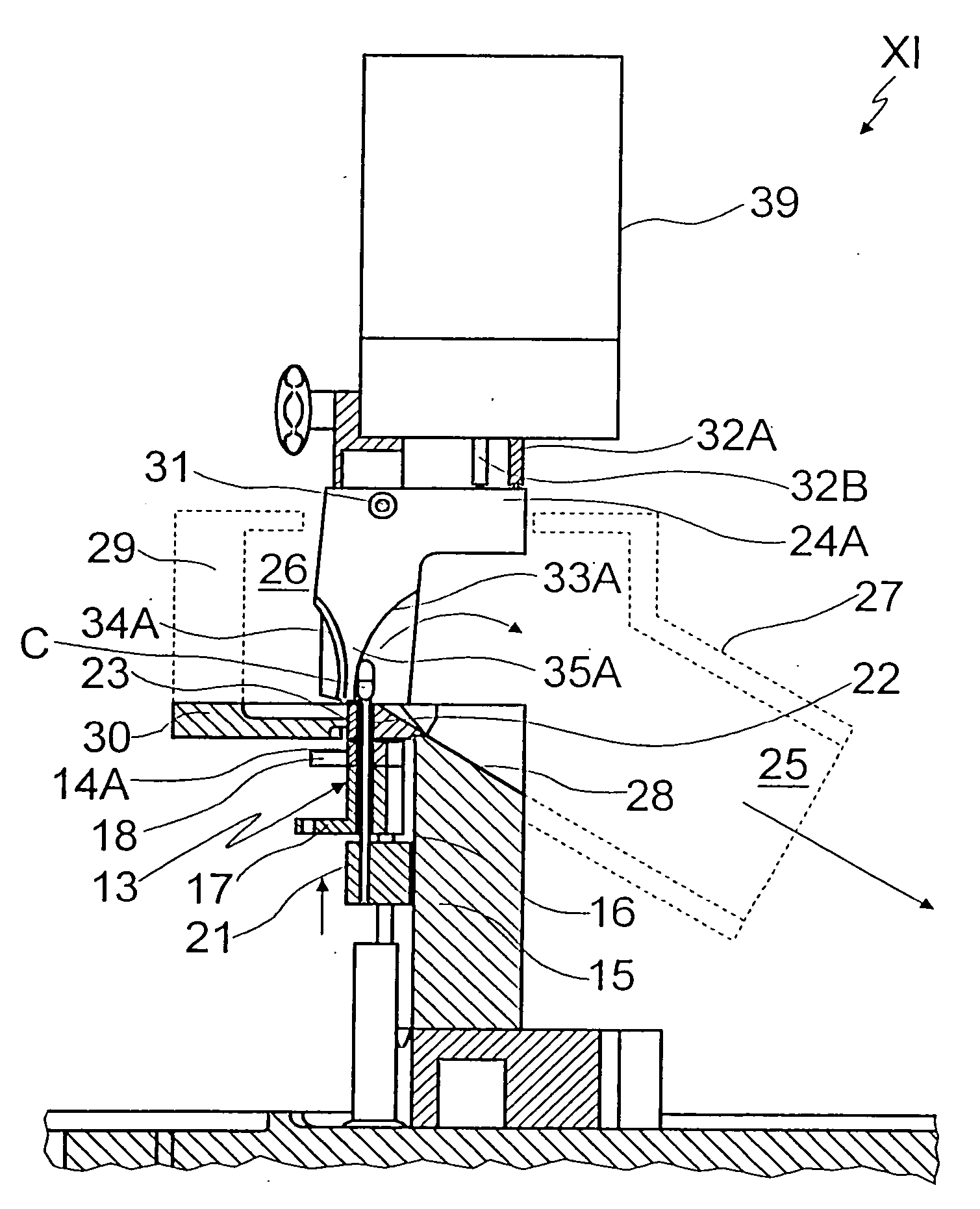

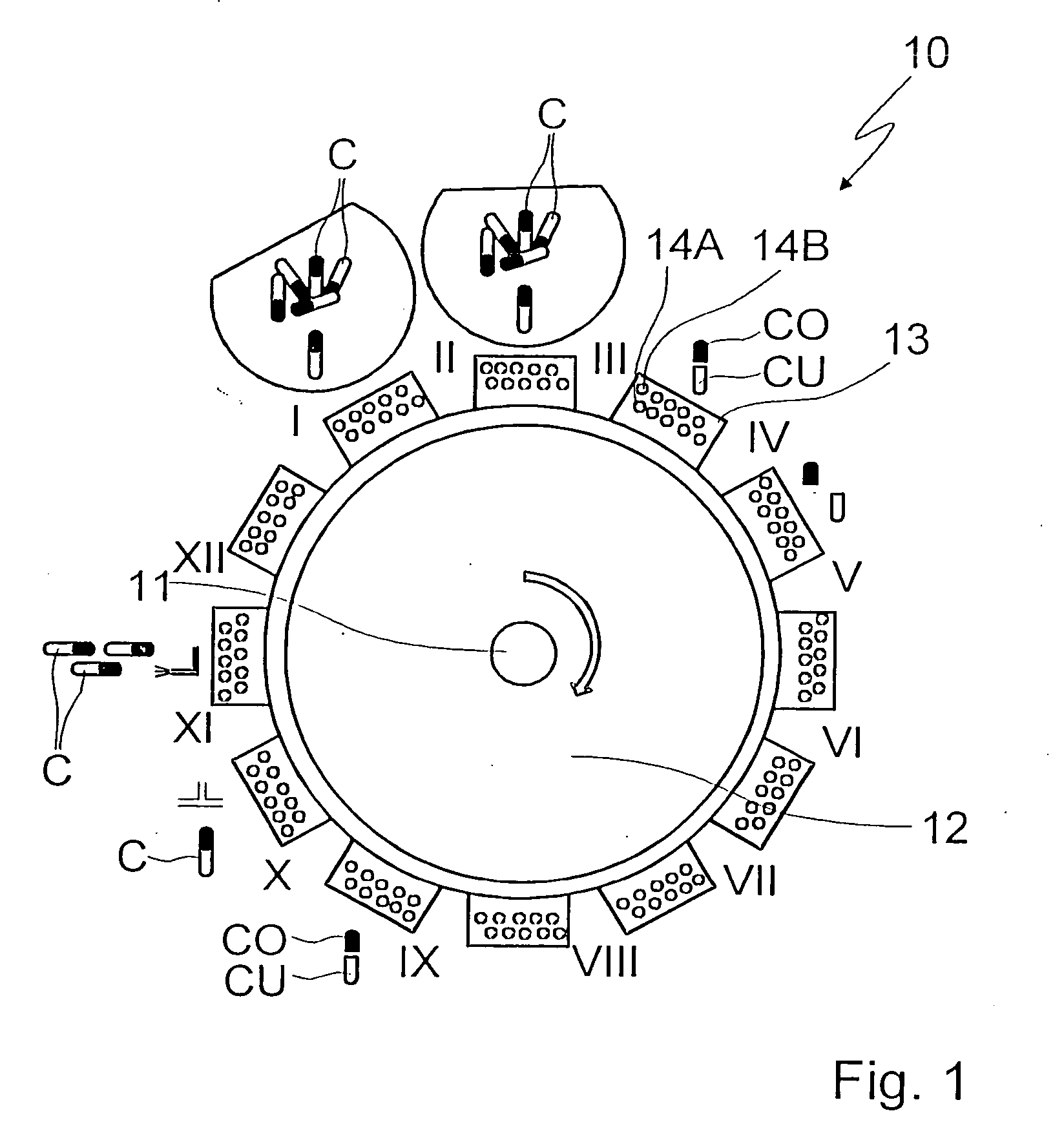

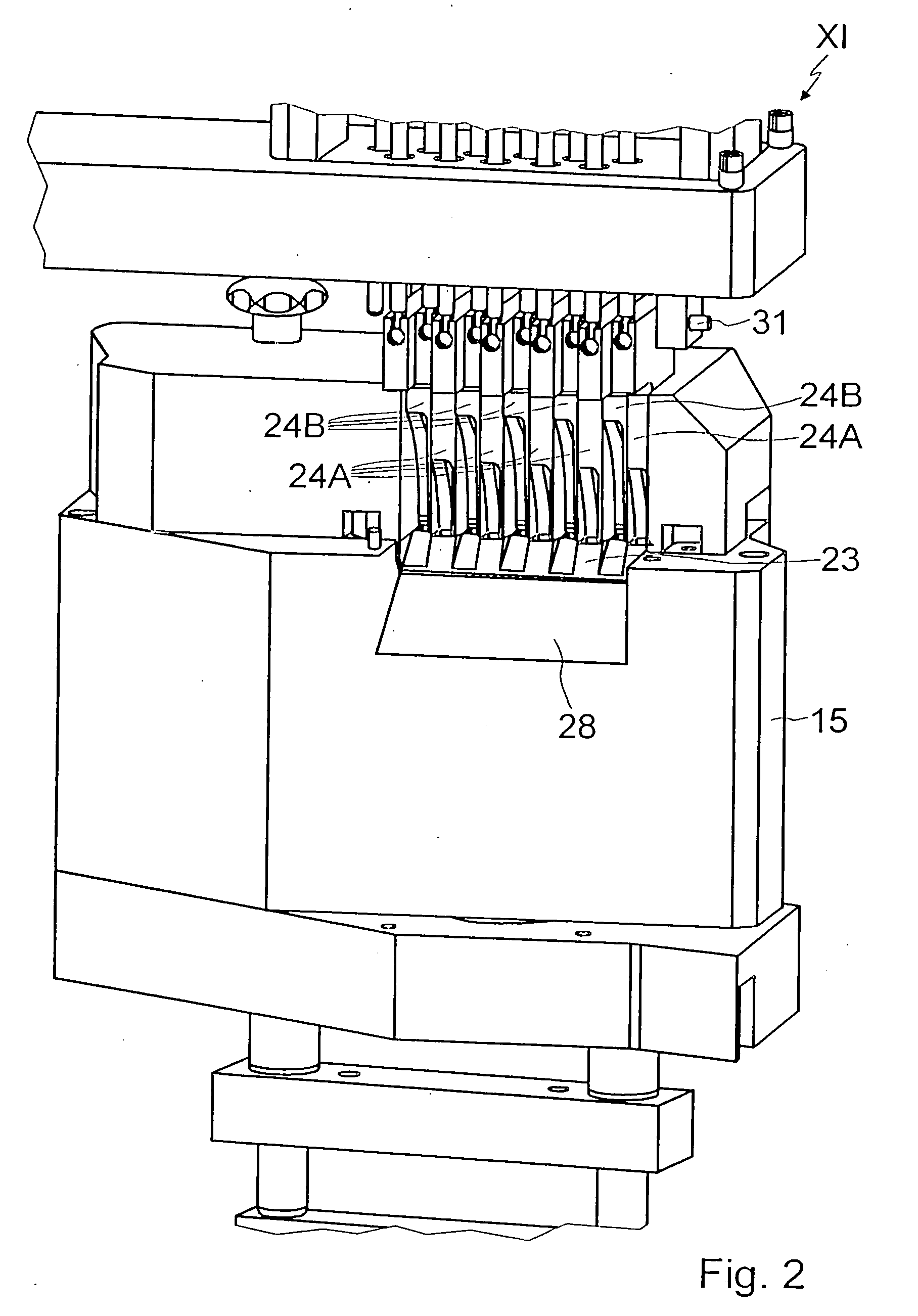

[0028] In FIG. 1, a machine 10 for filling and sealing capsules C is shown, each capsule comprising one lower capsule part CU and upper capsule part or cap CO. The machine 10 includes, as a capsule delivery device, a feed wheel 12 rotating in increments about a vertical shaft 11, by means of which wheel twelve work stations I through XII can be approached. To this end, the capsule delivery device 12 includes twelve carriers 13, in each of which two rows offset from one another longitudinally are embodied, each containing five receptacles 14A and 14B, each for one of the capsules C.

[0029] The individual work stations I through XII of the machine 10 have different tasks in the filling of the capsules C.

[0030] For instance, at work stations I and II, the capsules C that have been put together are sorted and introduced into the receptacles 14A of the first row and into the receptacles of the second row 14B of the respective carrier 13.

[0031] After the feed wheel 12, or the carrier 13...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com