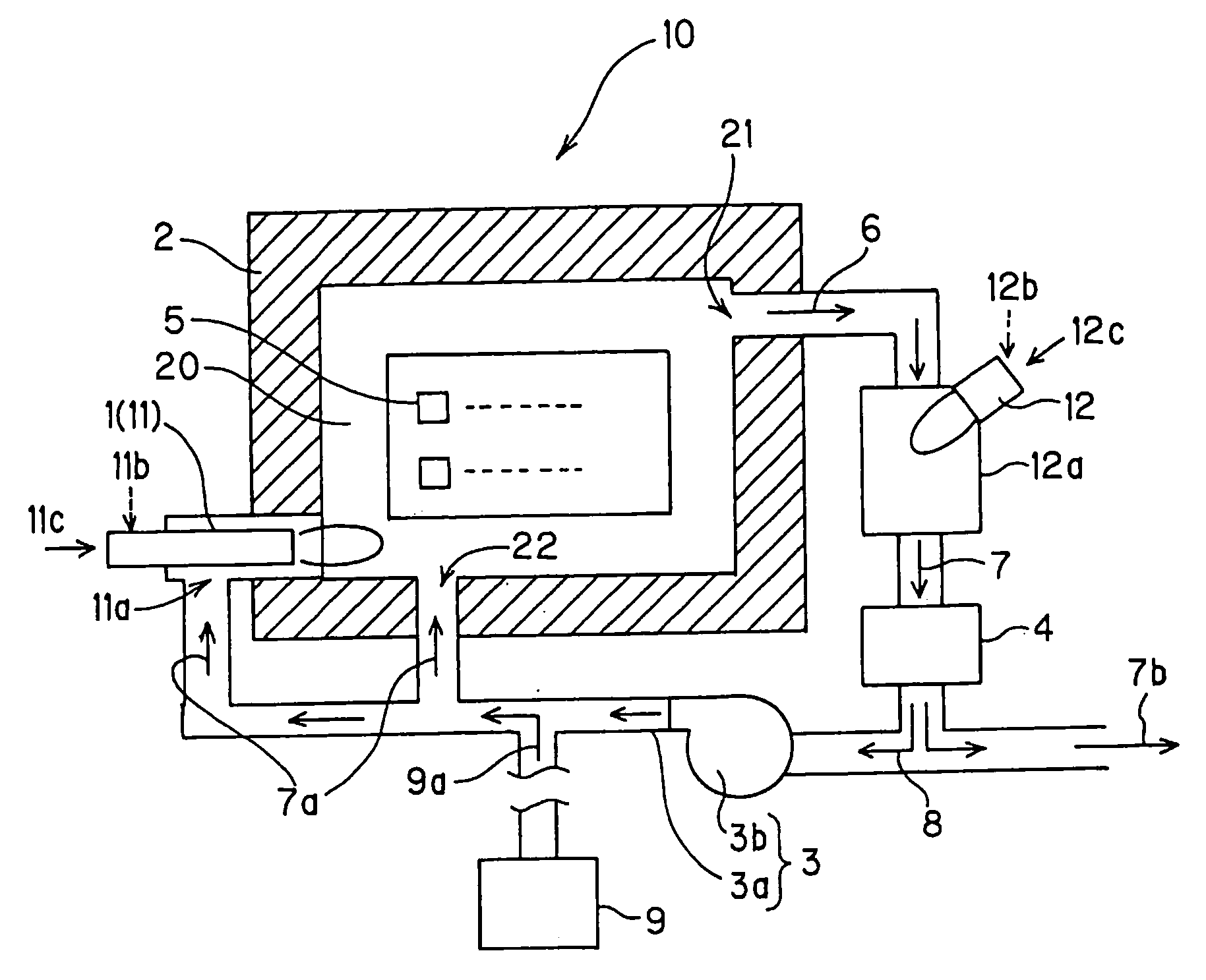

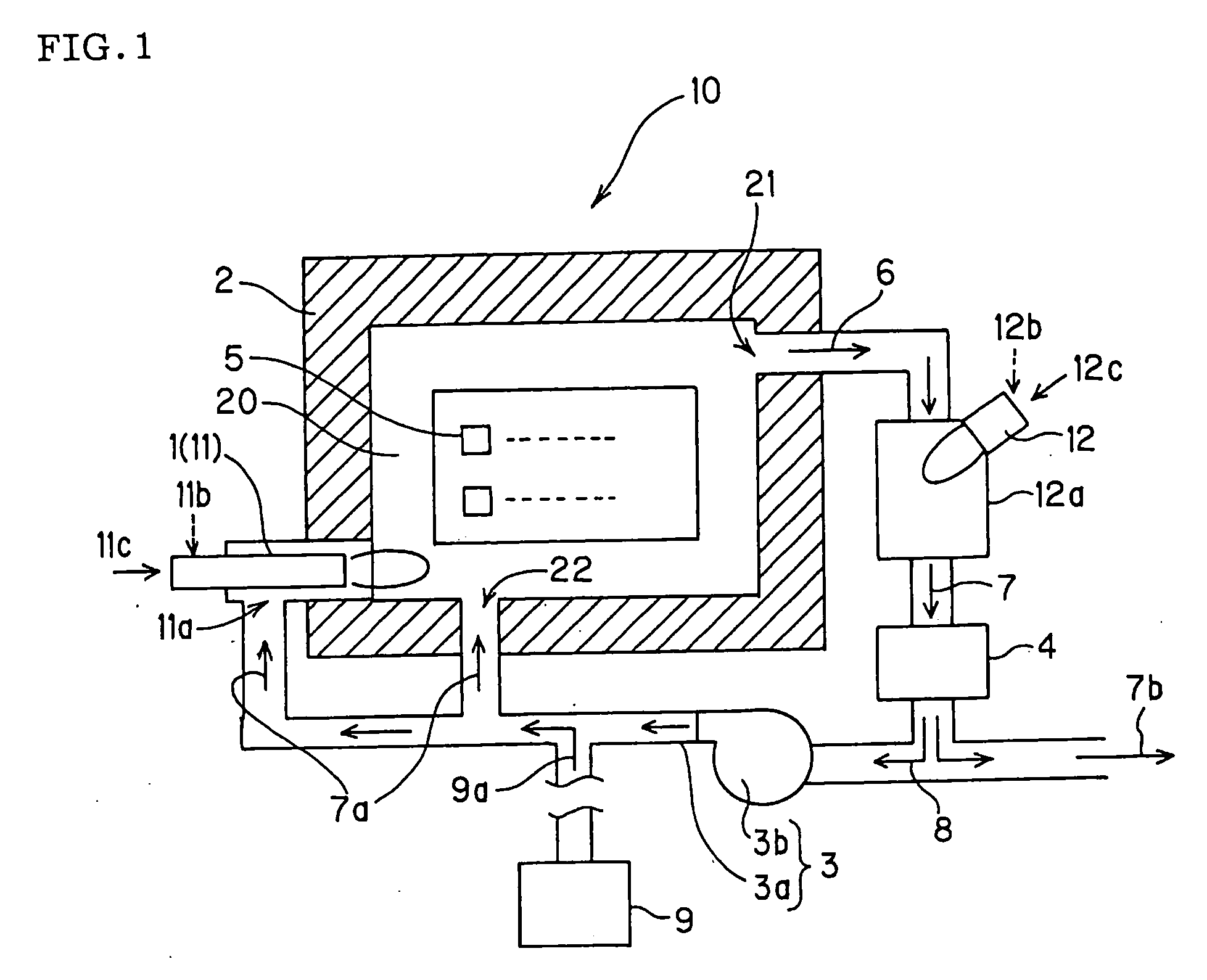

[0007] (1) A furnace (referred to as “a furnace according to a first aspect of the present invention” in some cases) includes a heating unit and a furnace body that can degrease an article to be degreased by heating the article with the heating unit, the article being disposed in the furnace body and containing an organic substance. The furnace body includes an outlet for discharging a degreasing gas containing a small amount of

gaseous oxygen and a large amount of gaseous organic decomposition products generated in an internal section of the furnace body during the degreasing of the article and also includes an inlet for receiving a

dilution gas, from outside, for reducing the concentration of the gaseous organic decomposition products in the furnace body to prevent the explosion of the gaseous organic decomposition products. The heating unit includes a first heater that can heat and degrease the article disposed in the furnace body and a second heater which heats the degreasing gas discharged from the outlet of the furnace body such that the gaseous organic decomposition products are removed and such that the degreasing gas is converted into a treatment gas containing a small amount of

gaseous oxygen. The furnace further includes a treatment gas-introducing unit for introducing the treatment gas for

dilution into the internal section of the furnace body from the second heater through the inlet and / or the first heater. The treatment gas is introduced into the internal section of the furnace body from the inlet and / or the first heater in such a manner that the treatment gas is circulated through the internal section of the furnace body, the outlet, the second heater, the treatment gas-introducing unit, and the inlet and / or the first heater, whereby the concentration of the gaseous organic decomposition products in the internal section of the furnace body is reduced such that explosion is prevented, whereby the concentration of gaseous

oxygen in the internal section of the furnace body is maintained low such that the article is prevented from being cracked due to the abnormal combustion of the gaseous organic decomposition products, and whereby the article can be degreased in a short time and then subjected to a subsequent firing step.

[0008] (2) A furnace (referred to as “a furnace according to a second aspect of the present invention” in some cases) includes a heating unit and a furnace body that can degrease an article to be degreased by heating the article with the heating unit, the article being disposed in the furnace body and containing an organic substance. The furnace body includes an outlet for discharging a degreasing gas containing a small amount of gaseous

oxygen and a large amount of gaseous organic decomposition products generated in an internal section of the furnace body during the degreasing of the article and also includes an inlet for receiving a

dilution gas, from outside, for reducing the concentration of the gaseous organic decomposition products in the furnace body to prevent the explosion of the gaseous organic decomposition products. The heating unit includes a third heater which heats the degreasing gas discharged from the outlet of the furnace body such that the gaseous organic decomposition products are removed and such that the degreasing gas is converted into a treatment gas containing a small amount of gaseous oxygen. The furnace further includes a treatment gas-introducing unit for introducing the treatment gas for dilution into the internal section of the furnace body from the third heater through the inlet. The treatment gas is introduced into the internal section of the furnace body from the inlet in such a manner that the treatment gas is circulated through the internal section of the furnace body, the outlet, the third heater, the treatment gas-introducing unit, and the inlet, whereby the concentration of the gaseous organic decomposition products in the internal section of the furnace body is reduced such that explosion is prevented, whereby the concentration of gaseous oxygen in the internal section of the furnace body is maintained low such that the article is prevented from being cracked due to the abnormal combustion of the gaseous organic decomposition products, and whereby the article can be degreased in a short time and then subjected to a subsequent firing step.

[0016] (10) A degreasing method (referred to as “a degreasing method according to a third aspect of the present invention” in some cases) includes a step of degreasing an article to be degreased using a furnace including a heating unit and a furnace body by heating the article with the heating unit and a firing step subsequent to the degreasing step, the article being disposed in an internal section of the furnace body and containing an organic substance. The furnace body includes an outlet for discharging a degreasing gas containing a small amount of gaseous oxygen and a large amount of gaseous organic decomposition products generated in the internal section of the furnace body during the degreasing of the article and also includes an inlet for receiving a dilution gas, from outside, for reducing the concentration of the gaseous organic decomposition products in the furnace body to prevent the explosion of the gaseous organic decomposition products. The heating unit includes a first heater that can heat and degrease the article disposed in the furnace body and a second heater which heats the degreasing gas discharged from the outlet of the furnace body such that the gaseous organic decomposition products are removed and such that the degreasing gas is converted into a treatment gas containing a small amount of gaseous oxygen. The furnace further includes a treatment gas-introducing unit for introducing the treatment gas for dilution into the internal section of the furnace body from the second heater through the inlet and / or the first heater. The treatment gas is circulated through the internal section of the furnace body, the outlet, the second heater, the treatment gas-introducing unit, and the inlet and / or the first heater, whereby the concentration of the gaseous organic decomposition products in the internal section of the furnace body is reduced such that explosion is prevented, whereby the concentration of gaseous oxygen in the internal section of the furnace body is maintained low such that the article is prevented from being cracked due to the abnormal combustion of the gaseous organic decomposition products, and whereby the article can be degreased in a short time and then subjected to the subsequent firing step.

[0018] (12) A degreasing method (referred to as “a degreasing method according to a fourth aspect of the present invention” in some cases) includes a step of degreasing an article to be degreased using a furnace including a heating unit and a furnace body by heating the article with the heating unit and a firing step subsequent to the degreasing step, the article being disposed in an internal section of the furnace body and containing an organic substance. The furnace body includes an outlet for discharging a degreasing gas containing a small amount of gaseous oxygen and a large amount of gaseous organic decomposition products generated in the internal section of the furnace body during the degreasing of the article and also includes an inlet for receiving a dilution gas, from outside, for reducing the concentration of the gaseous organic decomposition products in the furnace body to prevent the explosion of the gaseous organic decomposition products. The heating unit includes a third heater which heats the degreasing gas discharged from the outlet of the furnace body such that the gaseous organic decomposition products are removed and such that the degreasing gas is converted into a treatment gas containing a small amount of gaseous oxygen. The furnace further includes a treatment gas-introducing unit for introducing the treatment gas for dilution into the internal section of the furnace body from the third heater through the inlet. The treatment gas is circulated through the internal section of the furnace body, the outlet, the third heater, the treatment gas-introducing unit, and the inlet, whereby the concentration of the gaseous organic decomposition products in the internal section of the furnace body is reduced such that explosion is prevented, whereby the concentration of gaseous oxygen in the internal section of the furnace body is maintained low such that the article is prevented from being cracked due to the abnormal combustion of the gaseous organic decomposition products, and whereby the article can be degreased in a short time and then subjected to the subsequent firing step.

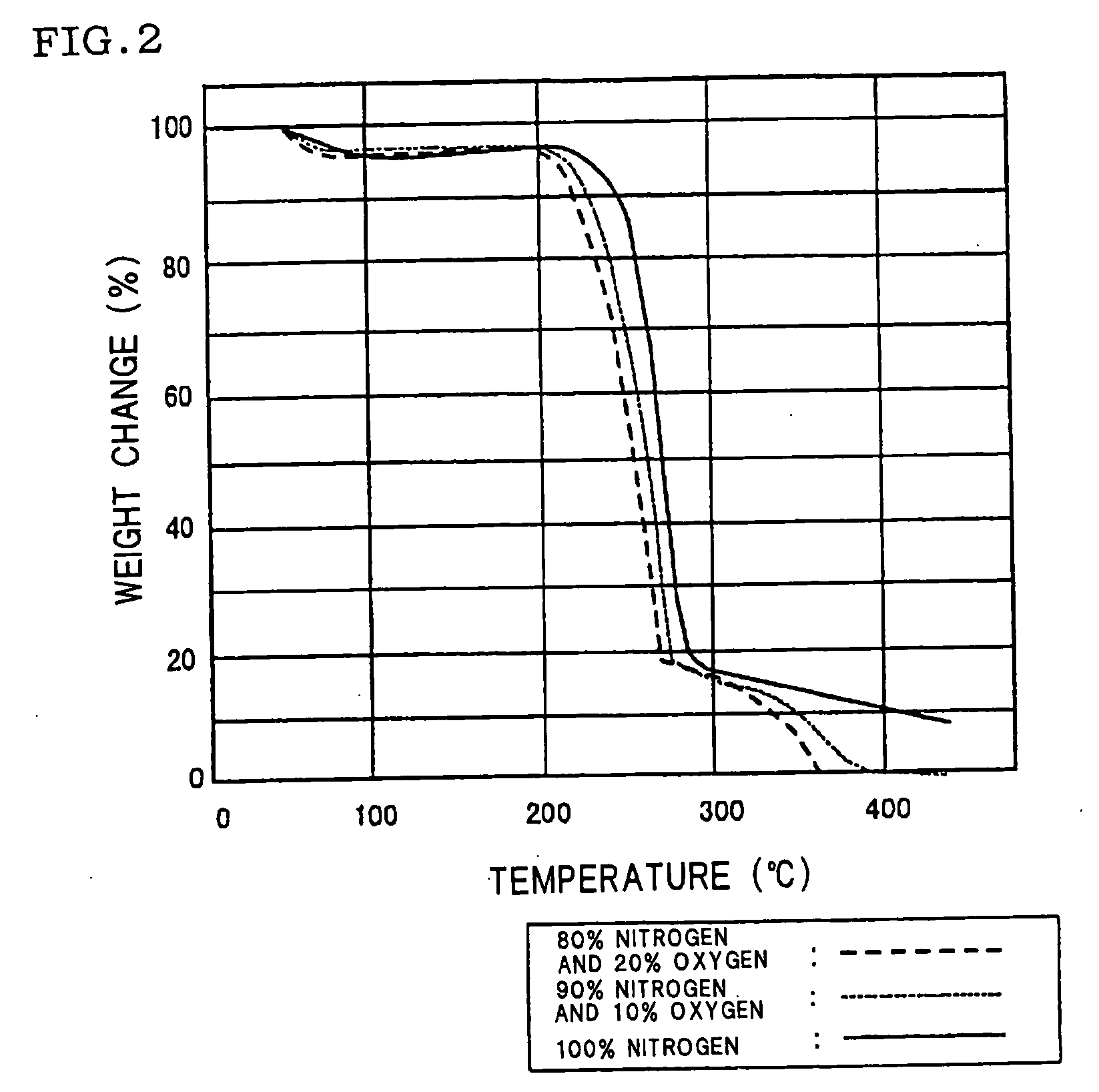

[0026] The present invention provides a furnace which can prevent an article to be degreased from being cracked due to the abnormal combustion of gaseous organic decomposition products in such a manner that the concentration of

oxygen gas in the furnace is maintained low and which can readily degrease the article at low cost in a short time and a degreasing method that is useful in readily obtaining a degreased article having no cracks at low cost in a short time.

Login to View More

Login to View More