Single field rotor motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

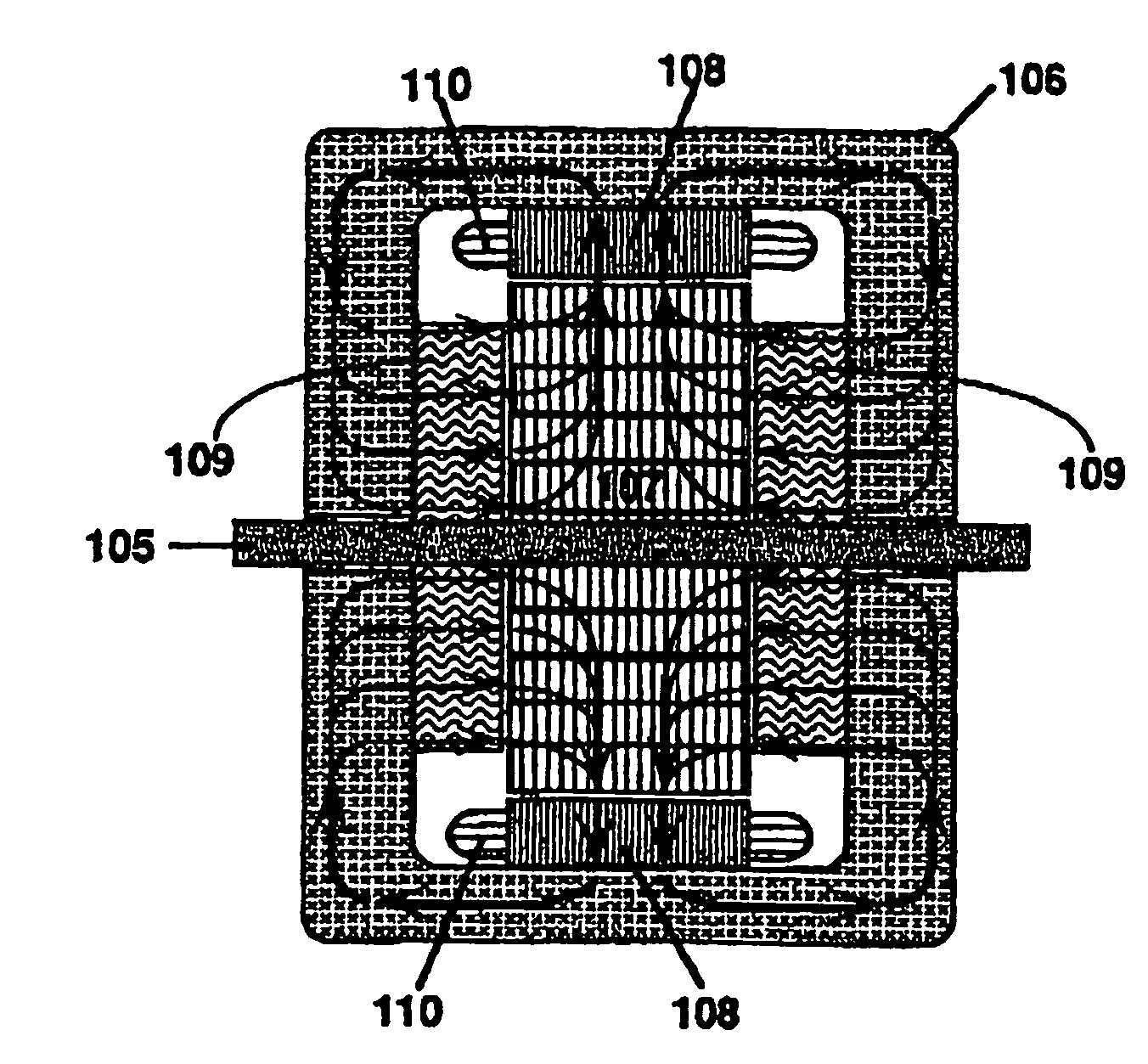

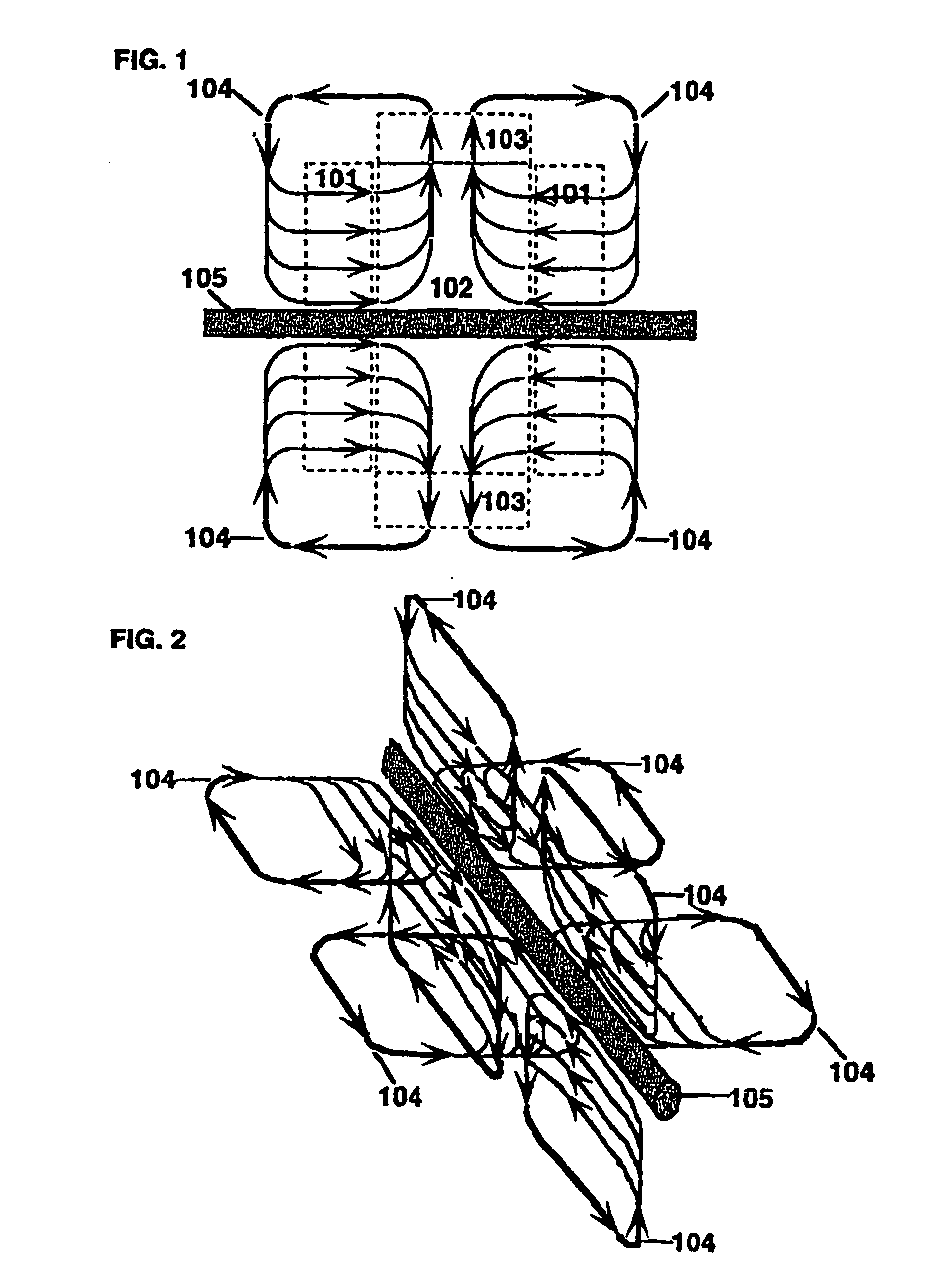

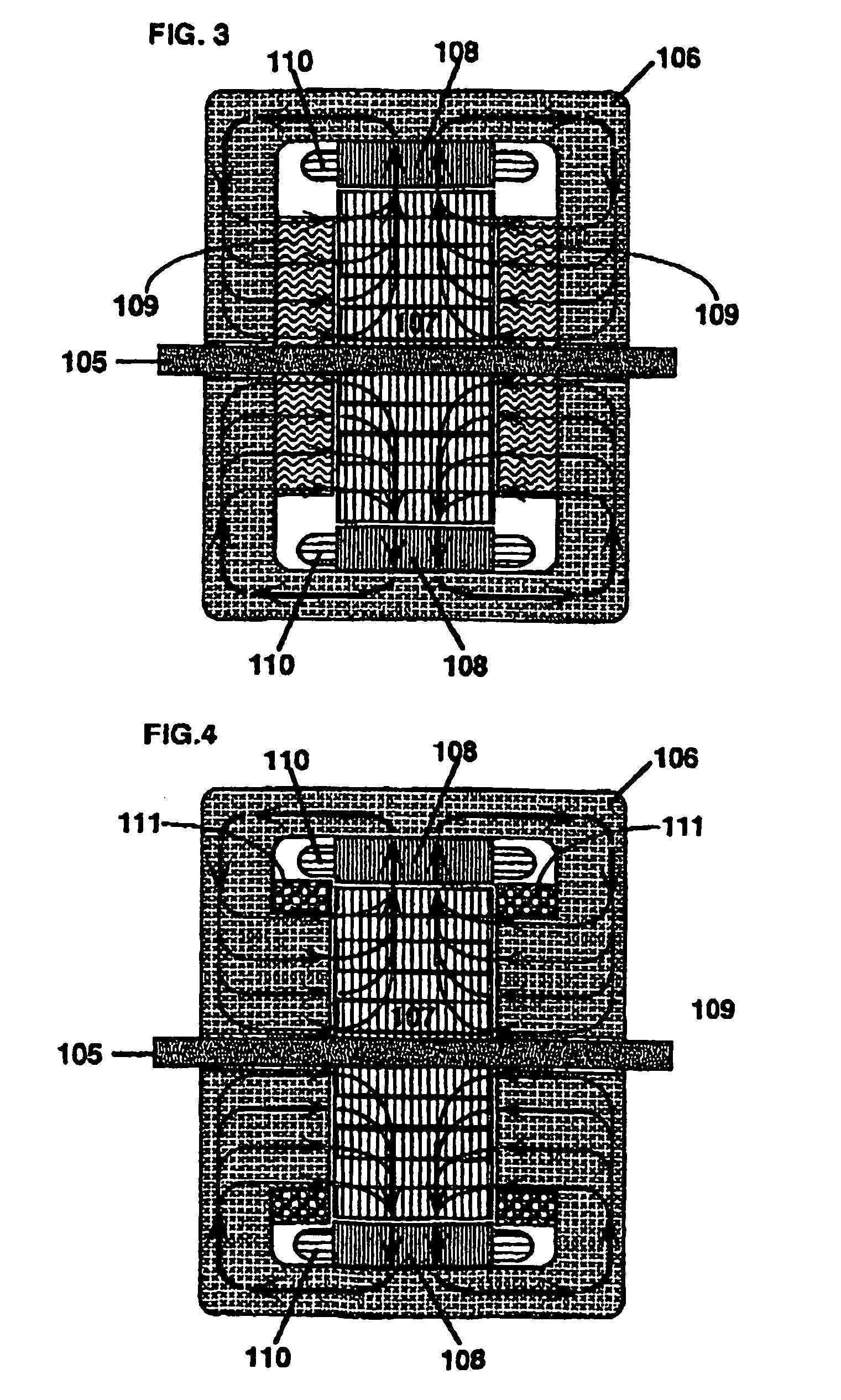

[0039]FIG. 1 schematically illustrates the configuration and paths of the primary torque flux in the single field rotor motor in accord with the invention regardless of whether the flux is created by permanent magnets or DC coils and cores of the stator. The areas illustrated and enclosed by dotted lines 101 is the area where the flux originates in the magnets or DC coil cores. The area in dotted line box 102 is the rotor-torque area of the motor where the rotor rotates and illustrates how the opposing polarity of the flux entering the rotor-torque area from opposite sides causes it to spray perpendicular to the motor axis. The rotor's laminations also are oriented perpendicular to the axis which further encourages this effect, and the laminations of the rotor become the ferrite path for the flux to travel to the circumference of the rotor where the rotor poles are formed. Areas 103 represent the areas of the stator which is laminated with poles and wound with phase coils and illust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com