Method and apparatus for moulding cosmetic products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

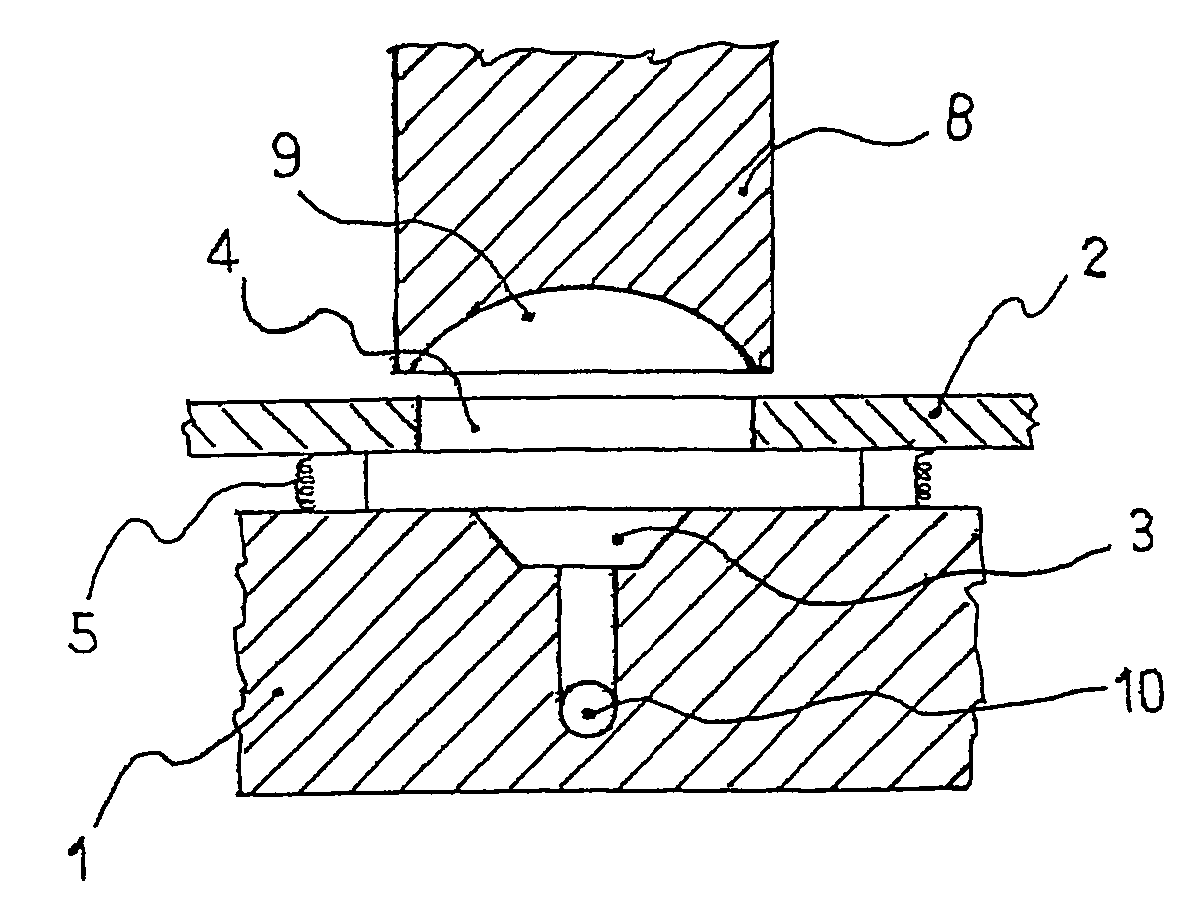

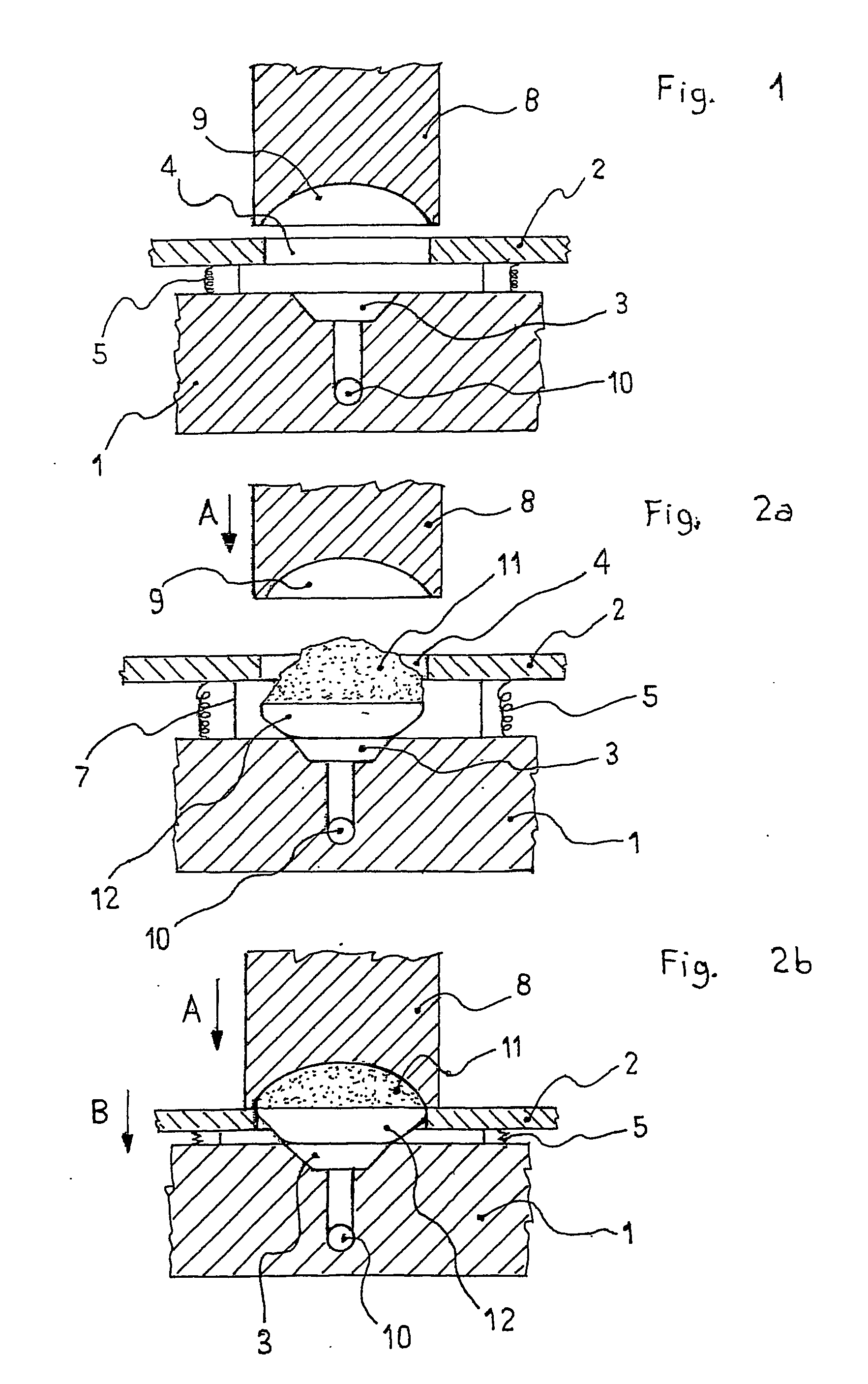

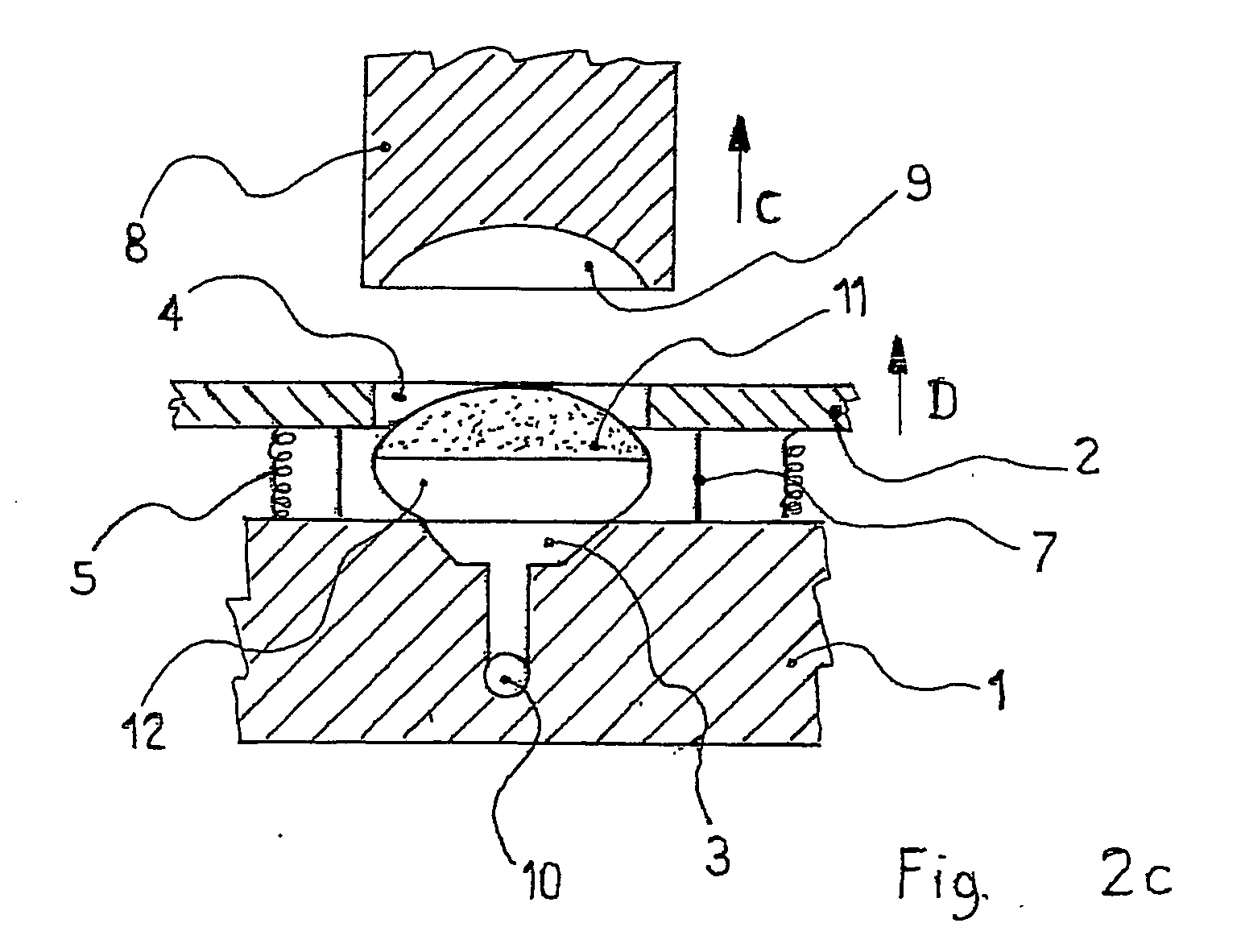

[0036] With reference to the figures, the apparatus for moulding a cosmetic product 11 on a housing, or container, 12, according to the present invention, comprises a support structure 1 equipped with holding means 3, 10 for one or more housings 12, and one or more punches 8 associated with said housings 12. The housings 12 are also equipped with a surface on which the cosmetic product 11 is contained and / or upheld during and after moulding, usually concave or flat in shape. According to the prior art, the punches 8 present a lower moulding surface 9 which reproduces, in the negative, the desired shape that the cosmetic product 11 is to assume on the housing 12, for example, as schematically shown in FIGS. 2a-2c, a simple spherical cap. Each of these punches 8, associated with a housing 12, is activated by known devices (not shown in the figures) in such a way as to compress the product 11 on the cosmetic product containing / upholding surface of the housing 12 which, in turn, is supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com