Washing machine

a washing machine and washing machine technology, applied in the field of washing machines, can solve the problems of inconvenient process steps, weak adhesive strength of double-sided tape or adhesive as time passes, and the washing machine with the receptacle has several problems, so as to achieve the effect of enhancing productivity and reducing the process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0038] A door assembly of a drum washing machine according to the present invention will be described in detail with reference to FIG. 4 to FIG. 6.

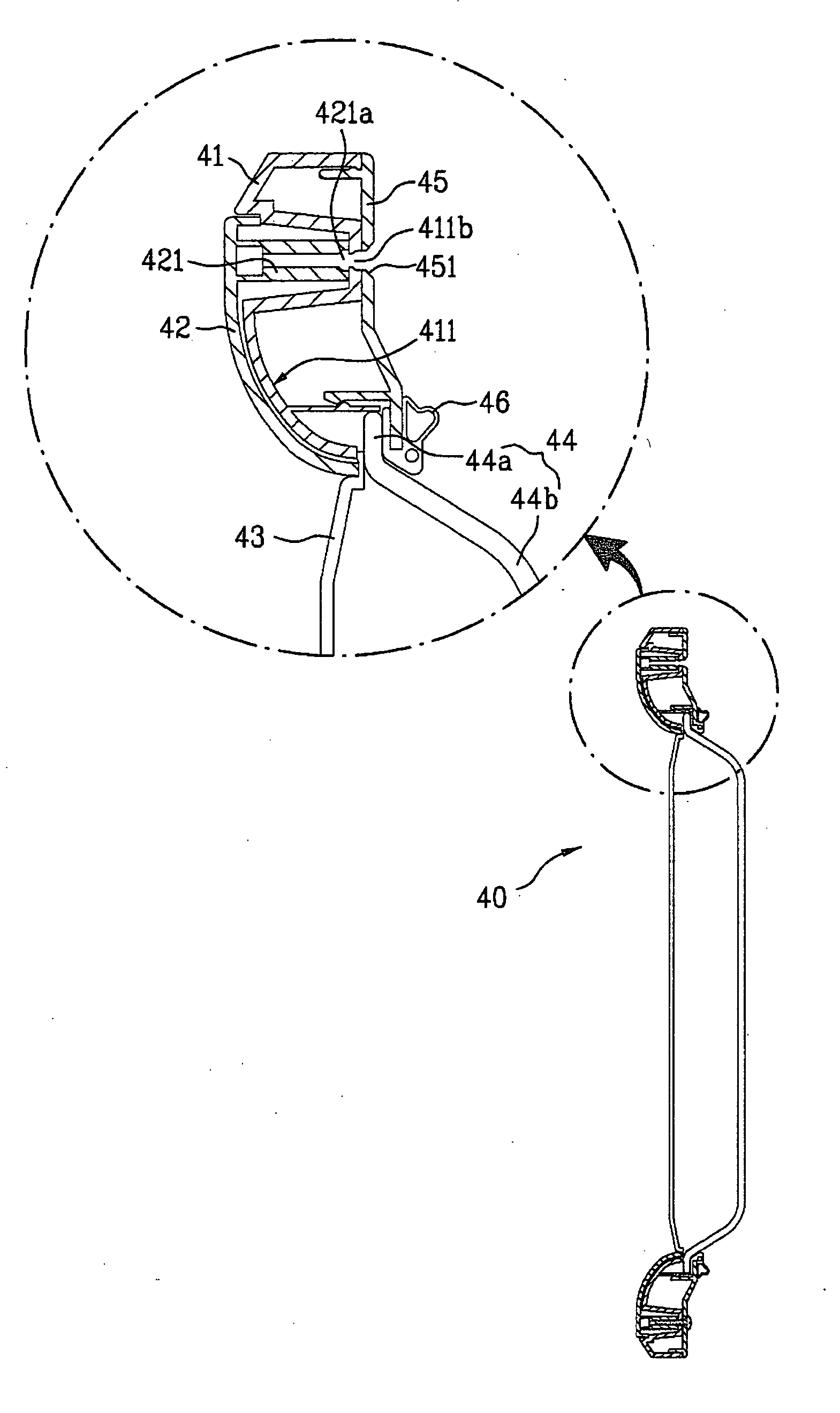

[0039] Referring to FIG. 4, a door assembly 40 includes a ring shaped outer frame 41 rotatably arranged at the front of a drum washing machine 1 (see FIG. 1) and provided with a plurality of insertion bosses 411, a door deco 42 provided with a plurality of fitting bosses 421 inserted into the insertion bosses 411 to be fixed to a front surface of the outer frame 41, a door cover 43 covering a central hole 412 of the outer frame 41 fixed to the door deco 42 from a rear surface of the outer frame 41, a door glass 44 closely adhered to a corner of the door cover 43, and an inner frame 45 fixed to the outer frame 41 at the rear of the door glass 44 so as not to avoid detachment of the door glass 44.

[0040] Preferably, the corner of the door deco 42 is provided with a plurality of hooks 422, and the outer frame 41 is provided with hook holes 4...

second embodiment

[0056] While the screw coupling structure of the door deco 42, the outer frame 41 and the inner frame 45 has been described, the assembly process of the door assembly 40 may be completed even though the door deco 42 is fixed to the inner frame 45. The coupling structure of the door deco 42 and the inner frame 45 is suggested as the present invention and will be described with reference to FIG. 7.

[0057] In the door assembly 40 according to the second embodiment of the present invention, the outer frame 41 is provided with a plurality of through holes 41a, and the door deco 42 is provided with a plurality of fitting bosses 421 inserted through the through holes 41a. Also, the inner frame 45 is provided with a plurality of fitting holes 451 corresponding to the fitting bosses 421.

[0058] In other words, as shown in FIG. 7, the fitting bosses 421 of the door deco 42 match with the fitting holes 451 of the inner frame 45 by passing through the through holes 411b formed in the outer frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com