Aluminum casting method with helium insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is disclosed herein primarily in respect to casting an aluminum turbocharger impeller wheel with an expendable mold. Typically, the mold is formed of permeable plaster, and molten aluminum is drawn into the mold cavity by applying suction to the exterior periphery of mold. However, it should be understood that the method may be applied to other molding processes and to other products, a few of which are briefly discussed herein.

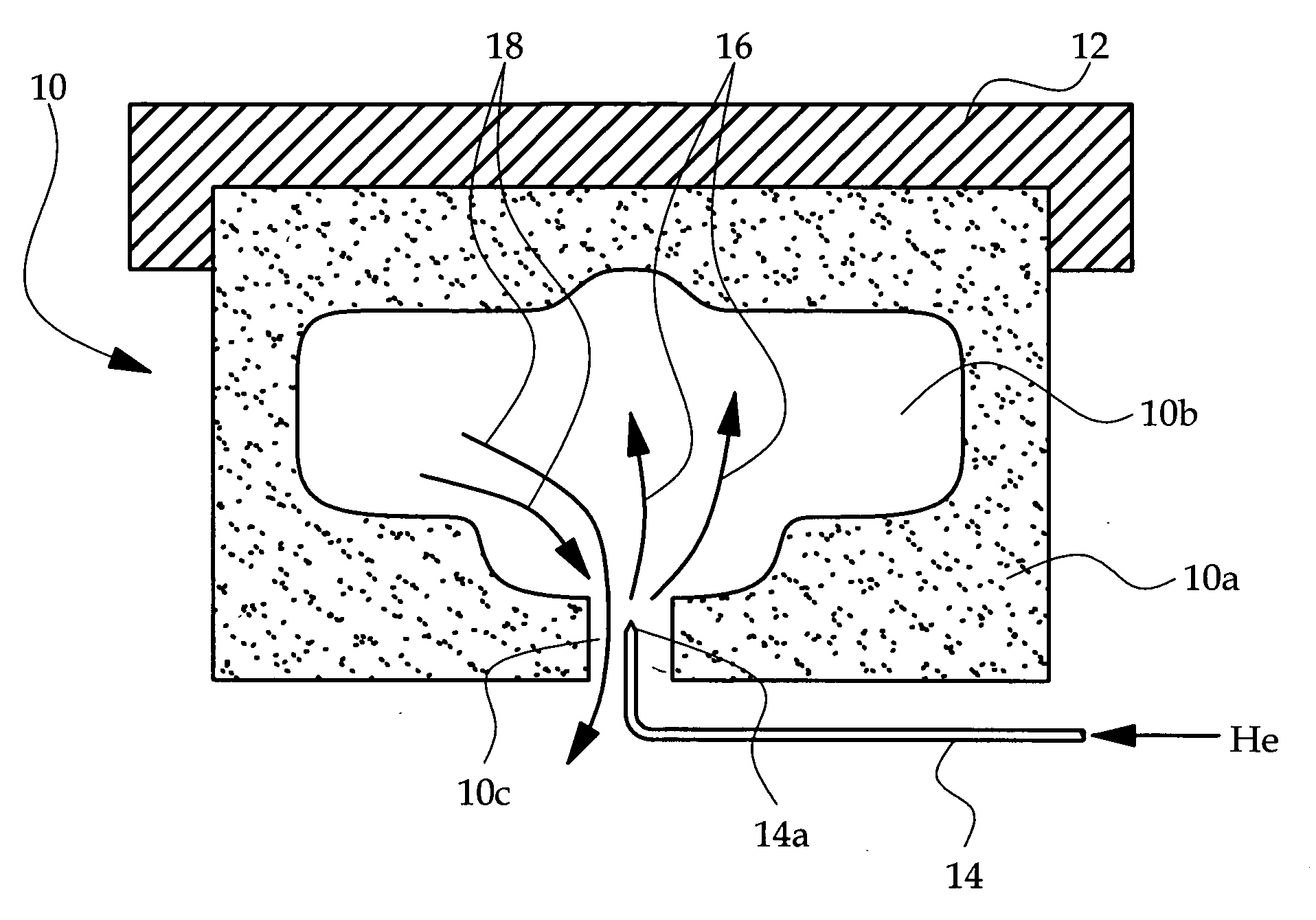

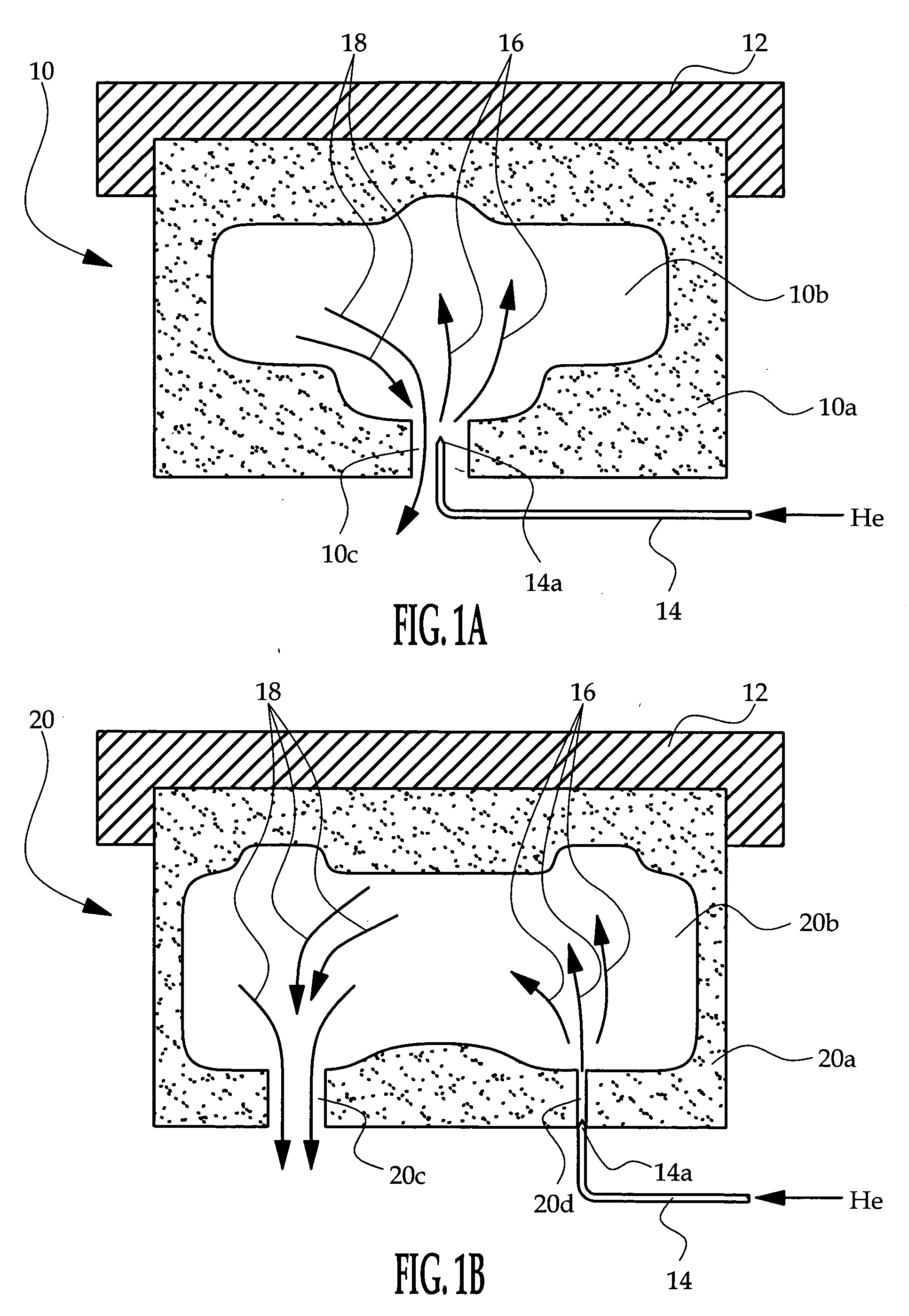

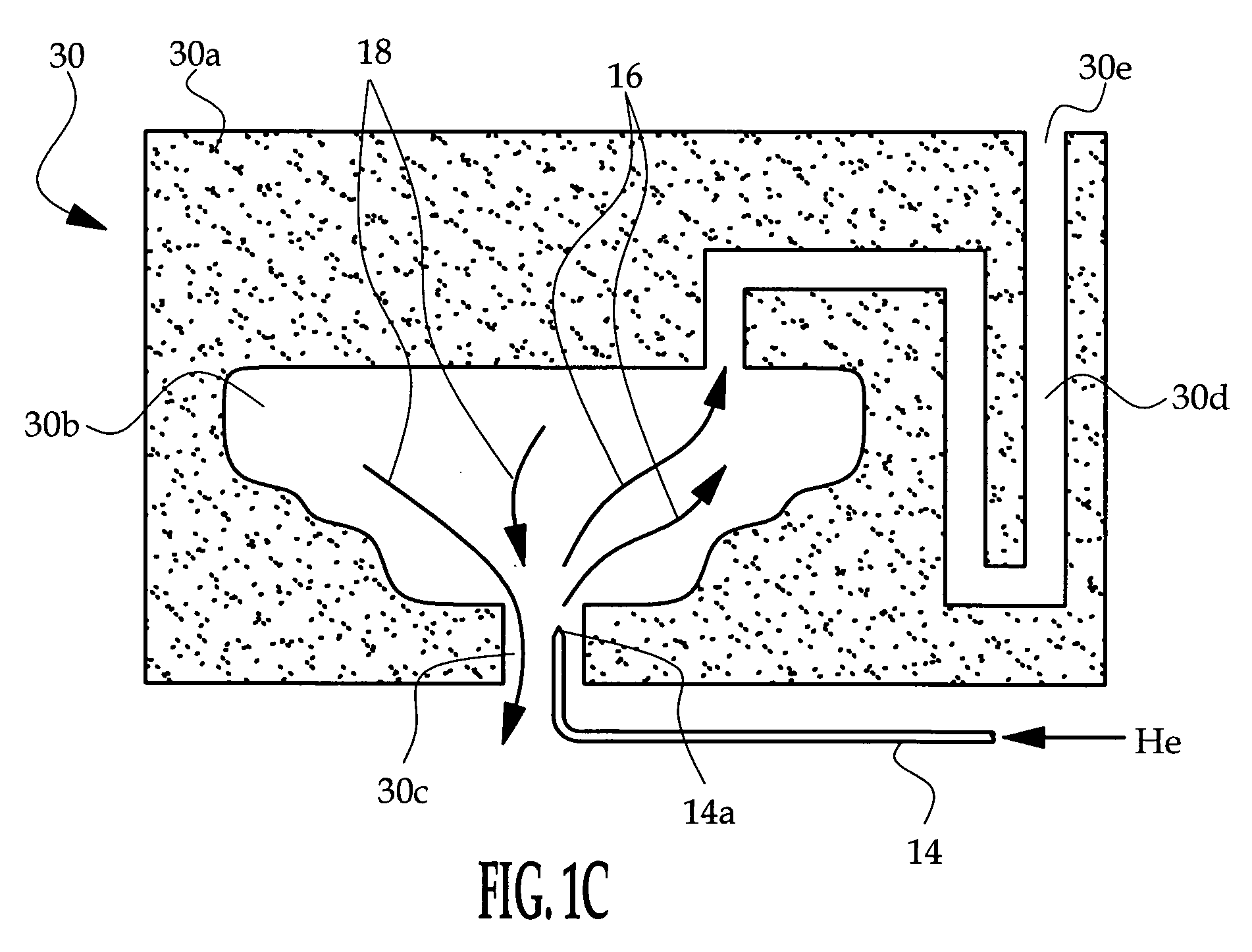

[0012] In general, the method of the present invention involves replacing atmospheric air in a top-sealed mold cavity with helium gas prior to introducing aluminium into the mold cavity. In addition to being inert, helium gas is lighter than air. When the helium gas is inserted through the fill tube or an opening in the bottom of the mold, it naturally rises into the mold cavity, expelling the atmospheric air that formerly occupied the mold cavity. FIGS. 1A and 1B illustrate the process as applied to a permeable plaster mold and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap