Measuring equipment and measuring method using cartridge container, and program recording medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

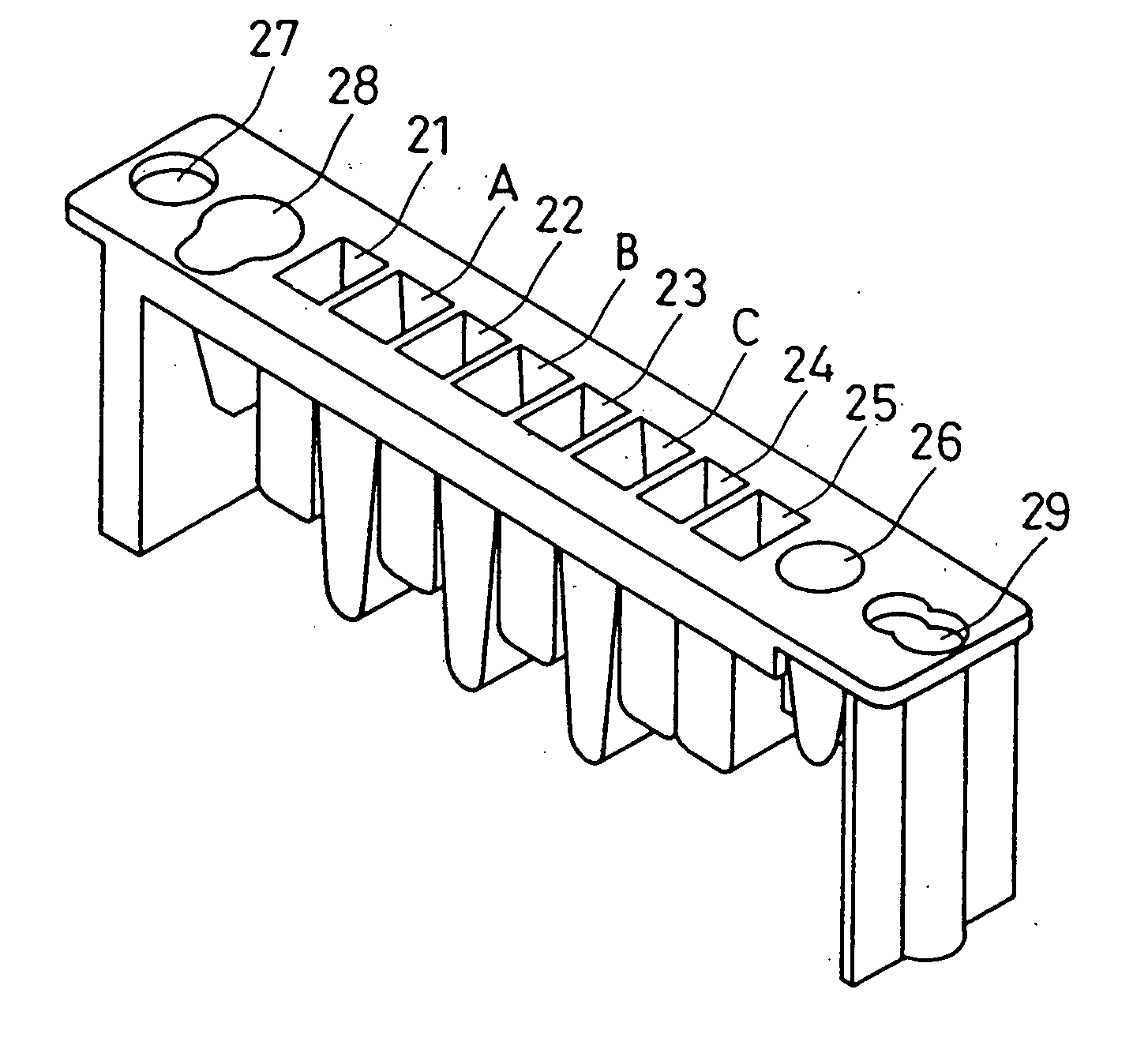

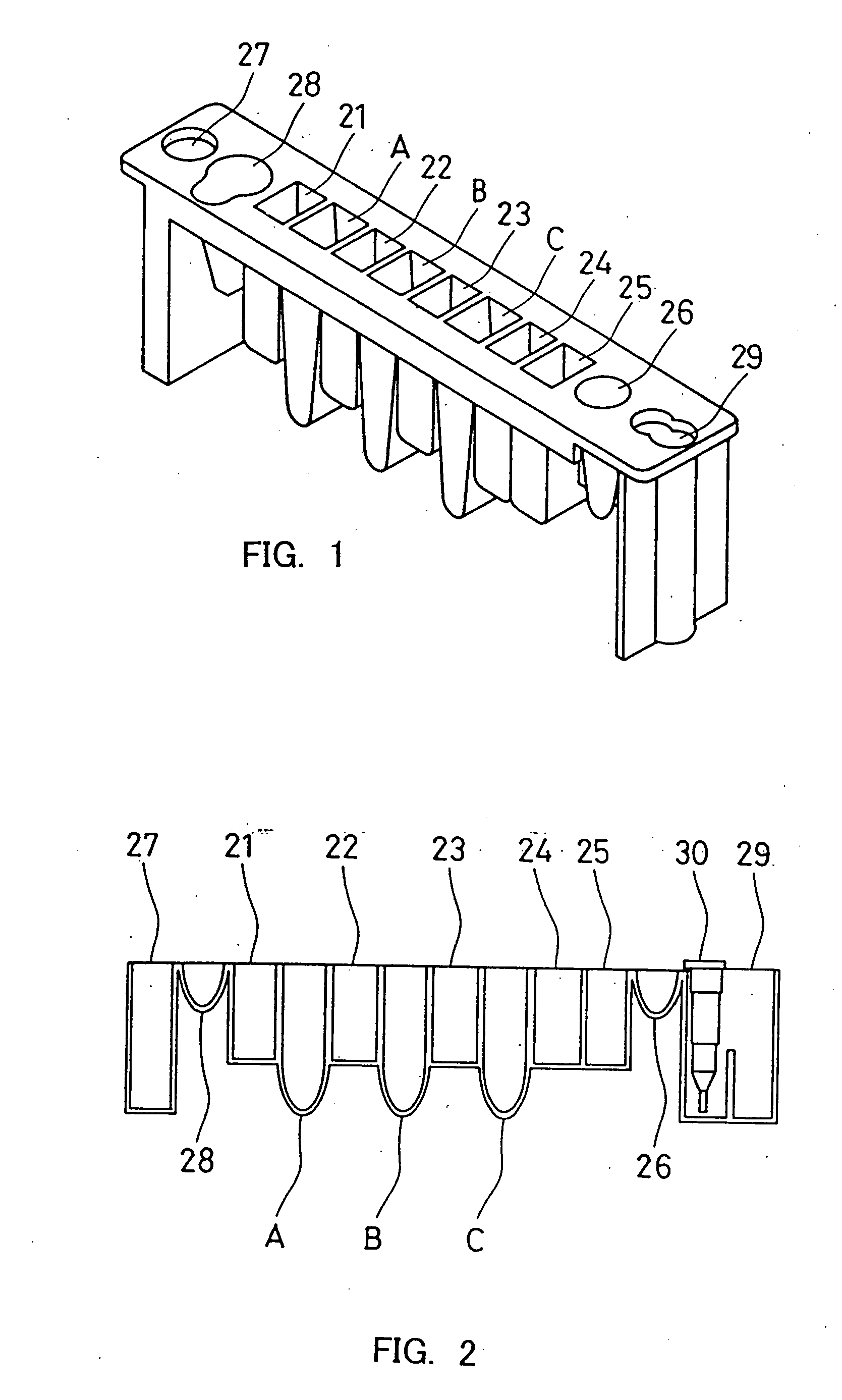

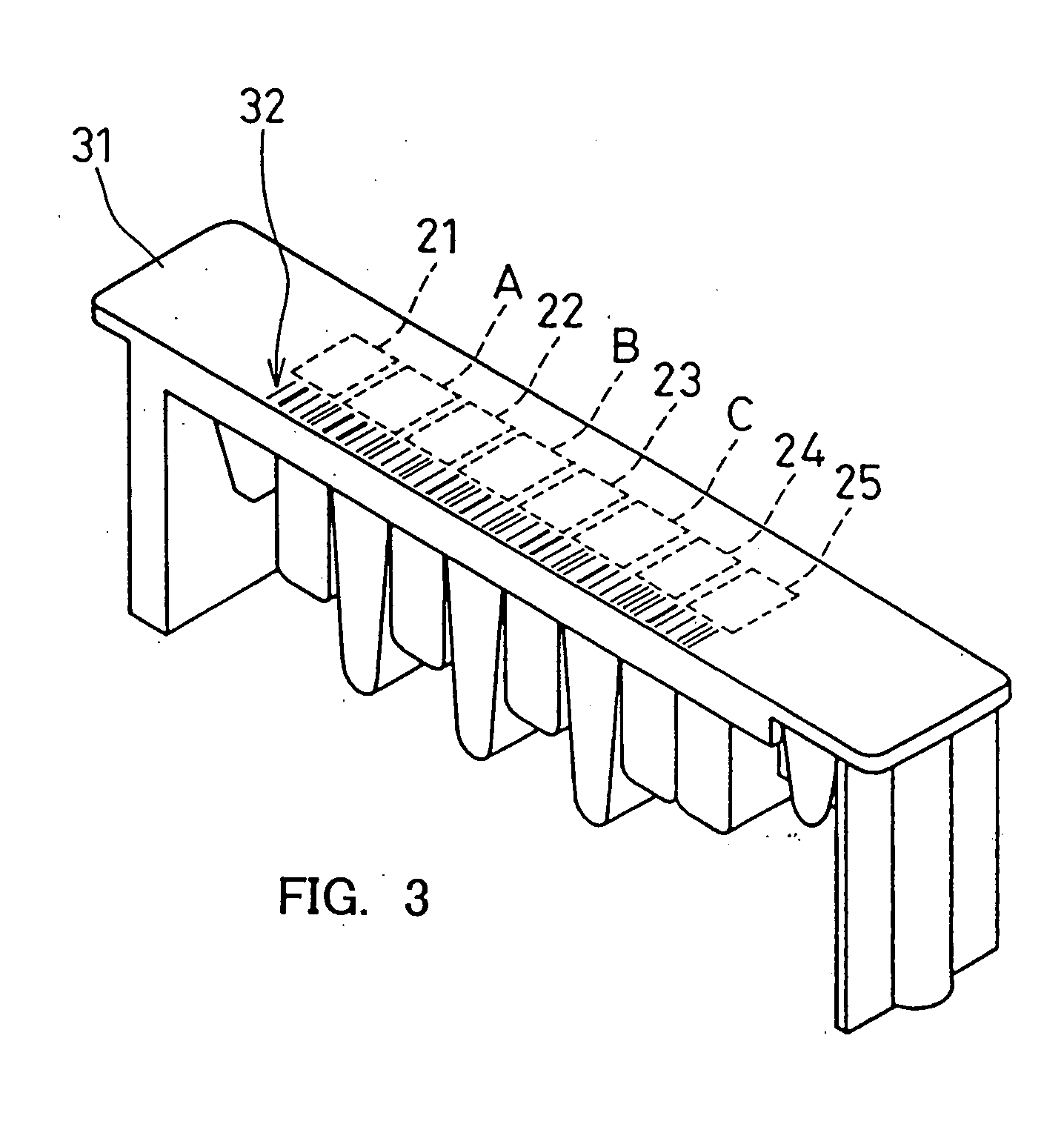

Image

Examples

example 1

[0098] In the present example, a prototype of the measuring equipment according to the present invention was built, and a cartridge container prepared by separately injecting general-purpose reagents into an empty cartridge container by hand was used to conduct a rheumatoid factor (RF) immunological nephelometric measurement. Then, these measurement results were compared with the equivalent measurement results obtained by a conventional automatic analyzer (manufactured by Nihon Denshi Co., Ltd.: Biochemical Automatic Analyzer JCA-BM8 (product name)). In addition, the aforementioned measuring equipment used in the present example was implemented by using conventional measuring equipment with the same hardware configuration as that shown in FIG. 4 in the aforementioned embodiment of the present invention and loading a program for performing the processes shown in FIG. 5 to FIG. 9 into its CPU. The measurements were carried out as follows:

[0099] (1) Various parameters such as a factor...

example 2

[0125] Measurements were conducted for specimens of whole blood in the present measuring equipment.

[0126] Two specimens of whole blood having different RF concentrations (EDTA, 2K blood added) were prepared. Then, the specimens were partially centrifuged to obtain blood plasmas, and at the same time, the rest was hemolyzed by freezing and thawing as whole blood samples.

[0127] As in Example 1, a cartridge container is prepared by separately injecting general-purpose reagents into an empty cartridge container to conduct the measurements of the blood plasmas and the whole blood. The measurement values of the RF concentrations in the obtained whole blood were subject to hematocrit conversion by determining the hematocrit values (%) from the Hb concentration obtained simultaneously (measurement values of RF in whole blood / (1-hematocrit value(%) / 100). This hematocrit conversion is conducted as an “arithmetic processing” shown in Step S456 of FIG. 8 and in Step S470 of FIG. 9 in the afor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com