Preservation skid

a technology of skids and skid bodies, applied in the field of skids, can solve the problems of time-consuming operation, high labor intensity, and high cost of preventing corrosion of assets, and achieve the effects of reducing time and personnel, reducing the risk of injury, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

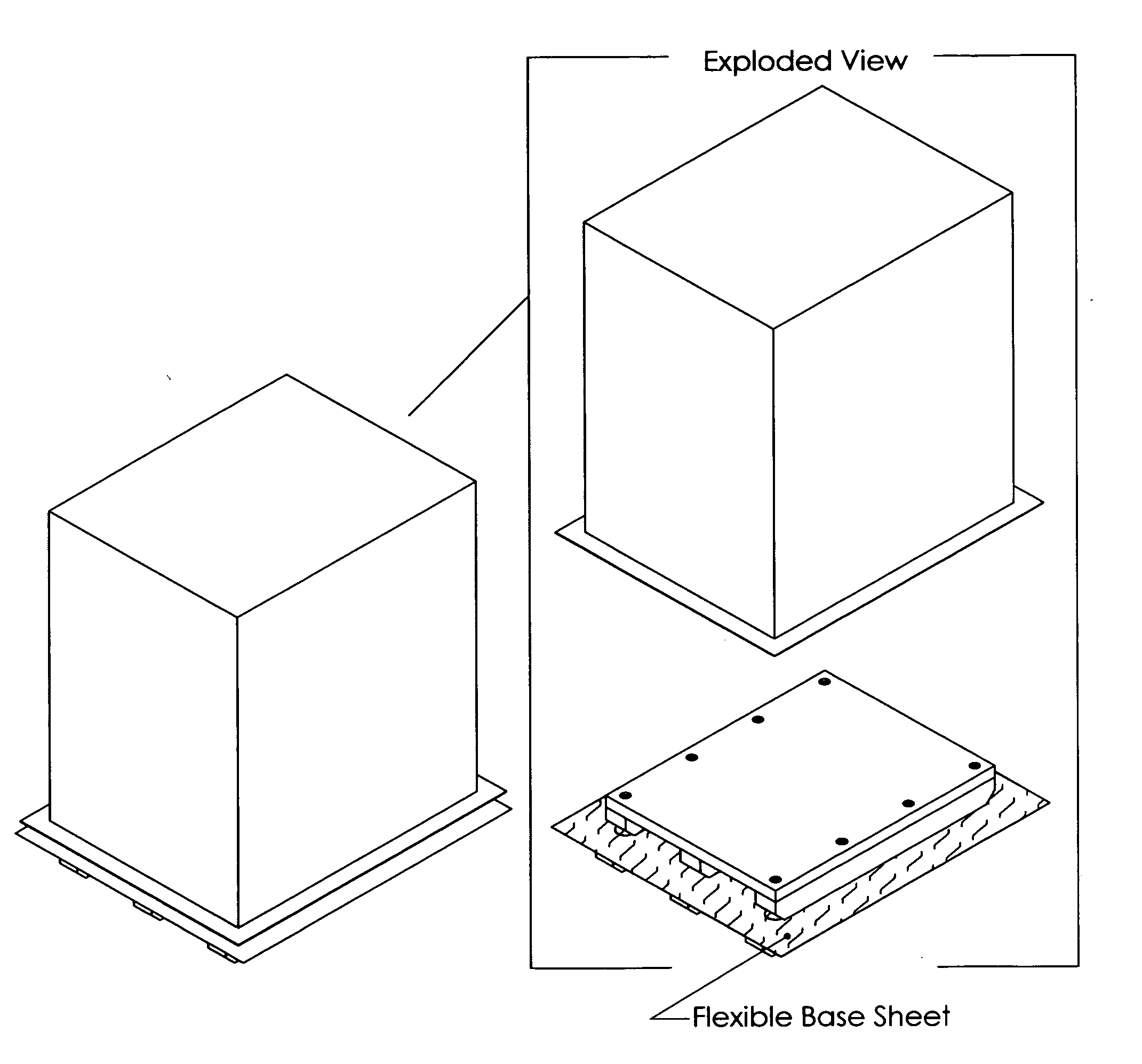

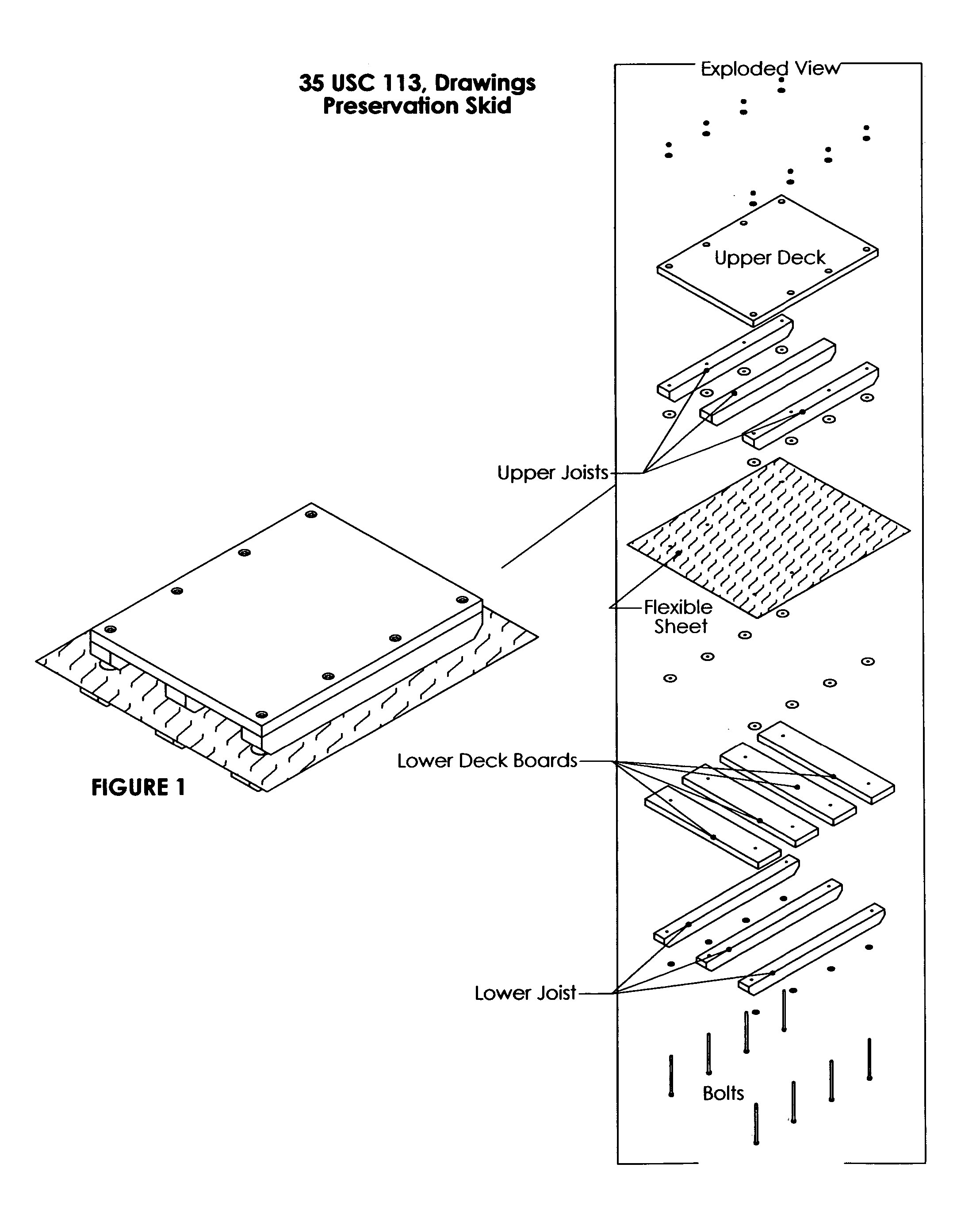

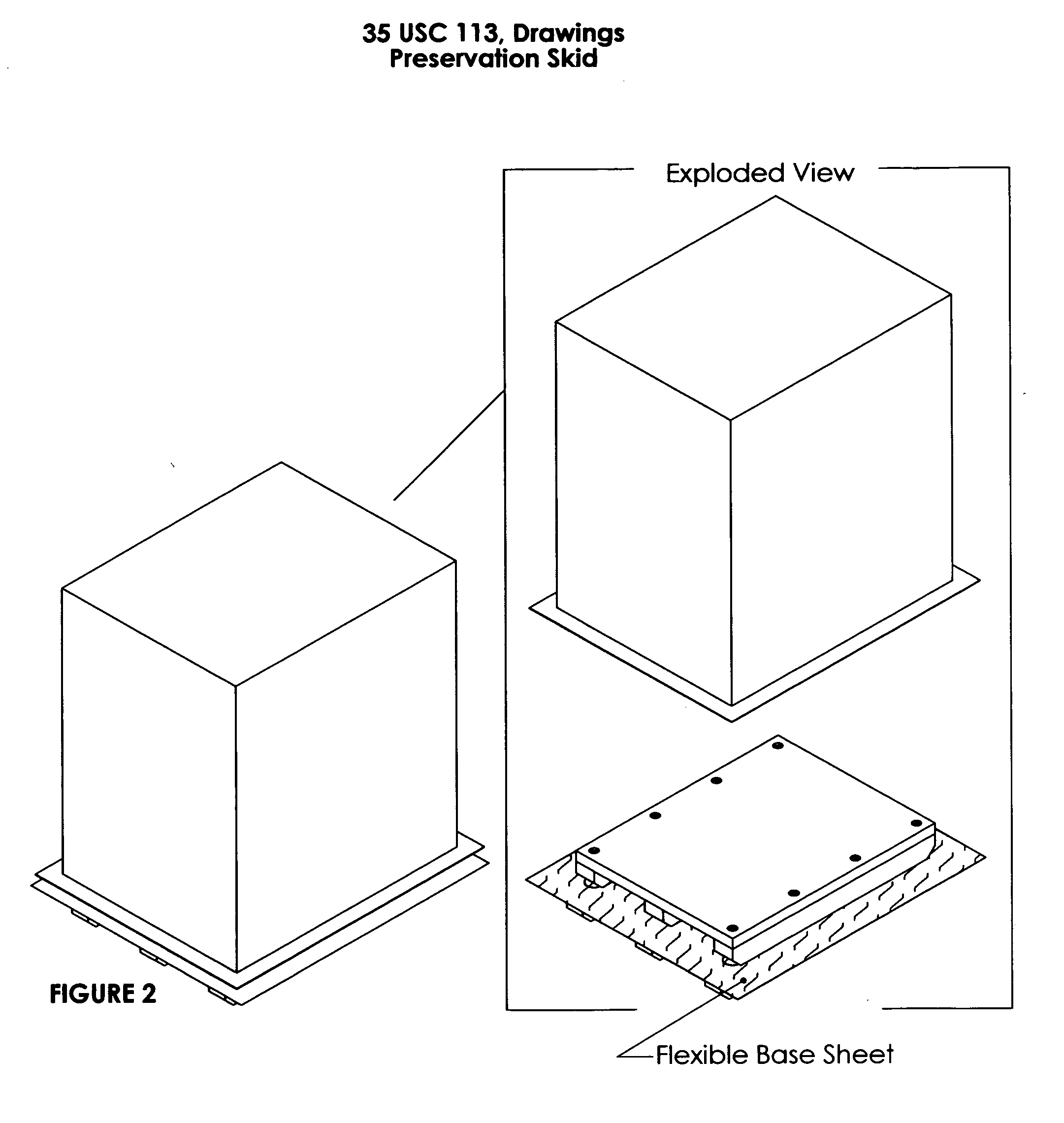

[0017] This invention is comprised of a skid which has a sheet of flexible packaging material “sandwiched” between two layers of rigid material in a hermetic or air-tight fashion, and that extends out beyond the edges of the rigid materials (see FIGS. 1, 5, 7 and 8). For the purpose of this description, a skid shall be defined as an assembly of rigid parts onto which an asset or product may be placed for the purpose of moving the asset or product. The skids construction shall consist of two or more stringers that are placed upon the floor, all in parallel alignment with one another and of sufficient thickness so as to allow a lifting device (such as the forks of a lift truck of pallet jack) to fit between the stringers and beneath deck boards which get fastened to the upper faces of the stringers. The deck boards shall be positioned at 90° to the stringers and all deck boards shall be parallel to one another (see FIG. 3).

[0018] This invention can be configured in numerous ways. One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com