Multi metal base hardfacing alloy

a hardfacing alloy and metal base technology, applied in the field of metal materials, can solve the problems of reducing the hardness of metal materials, and reducing the tensile strength, so as to reduce the cost of welding process, enhance hardfacing strength, and reduce the preheating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The content of the present invention is illustrated in detail in the following part by embodiments making reference to the drawings. The symbols mentioned in the specification refer to the symbols in the drawings.

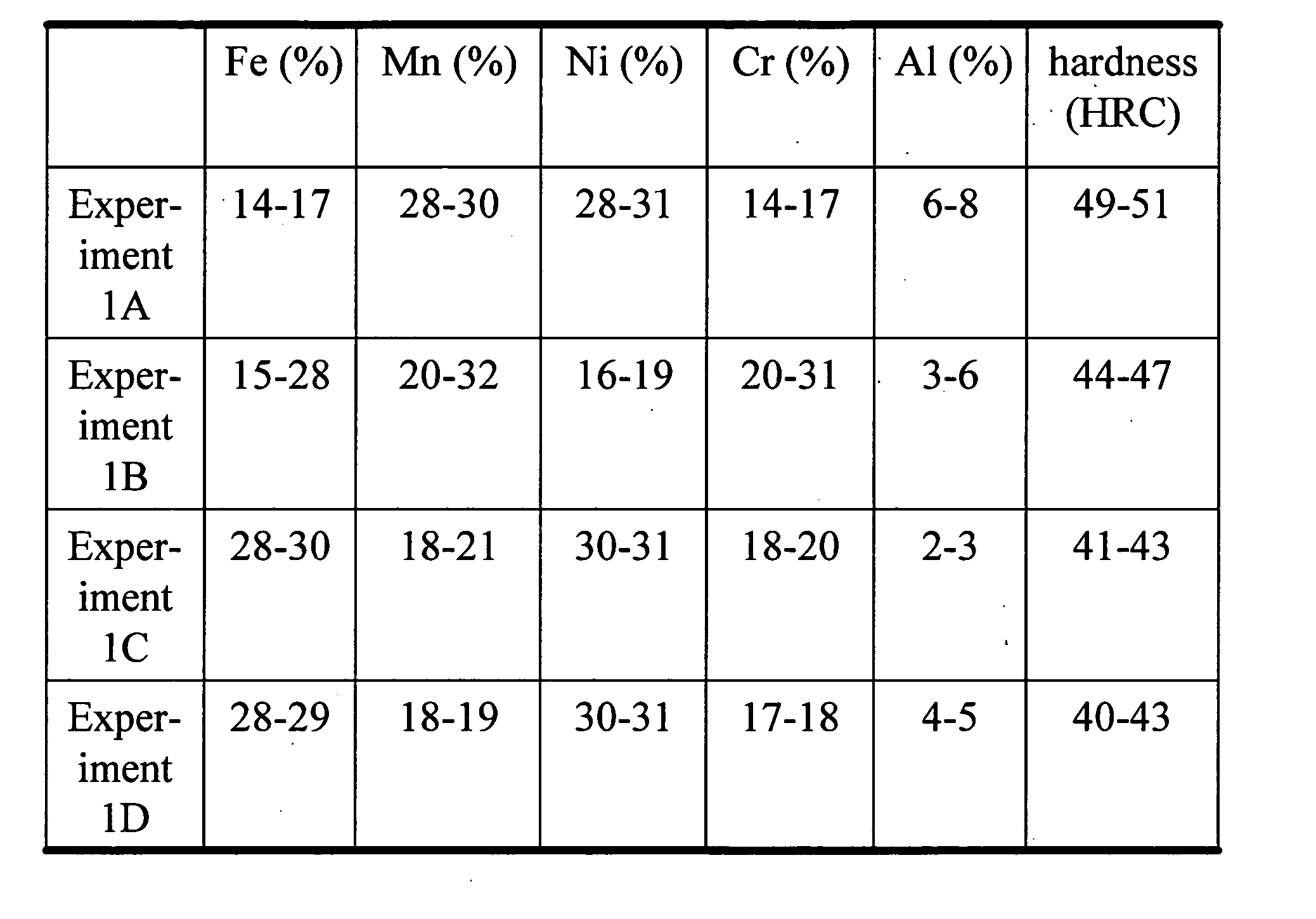

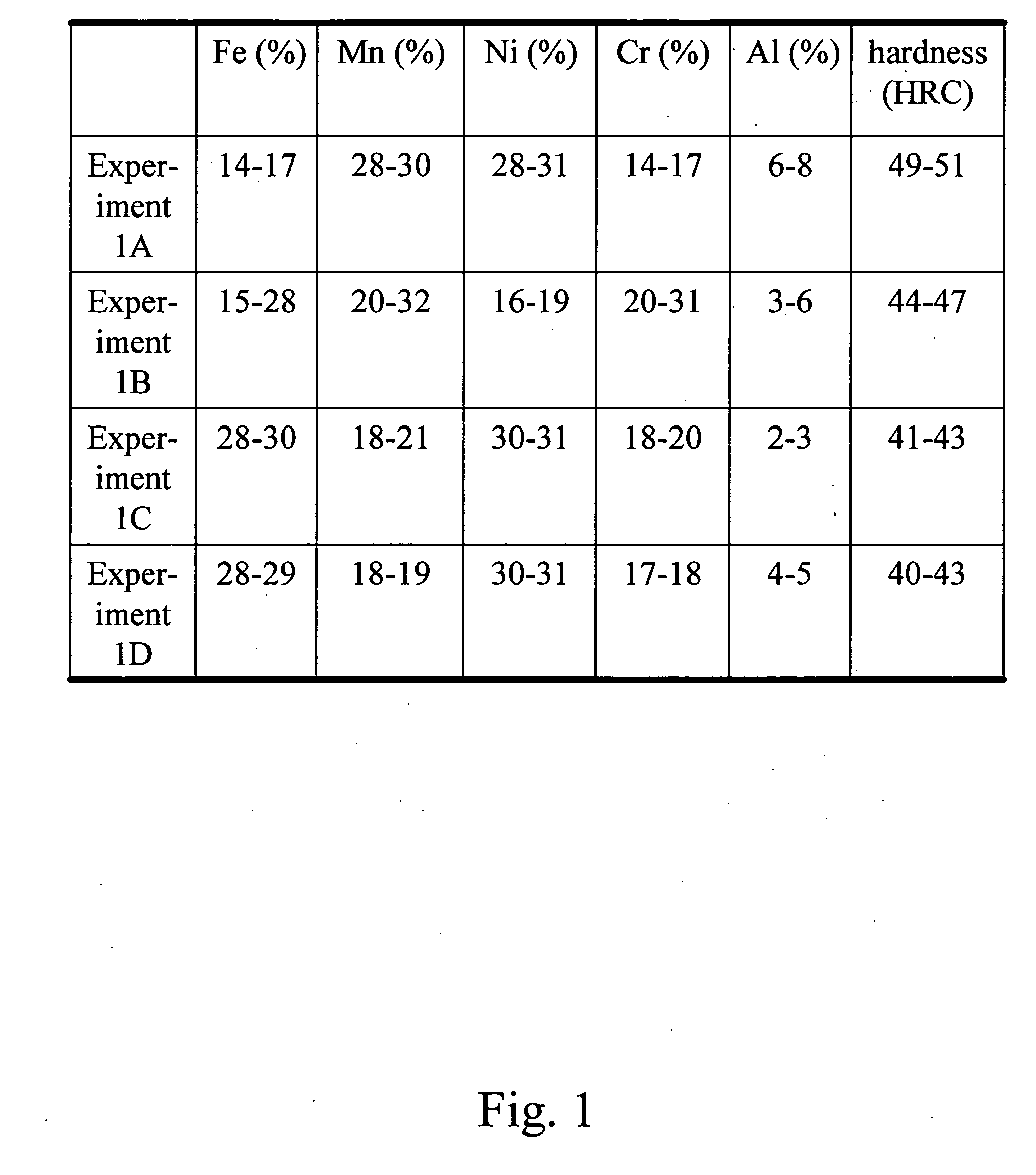

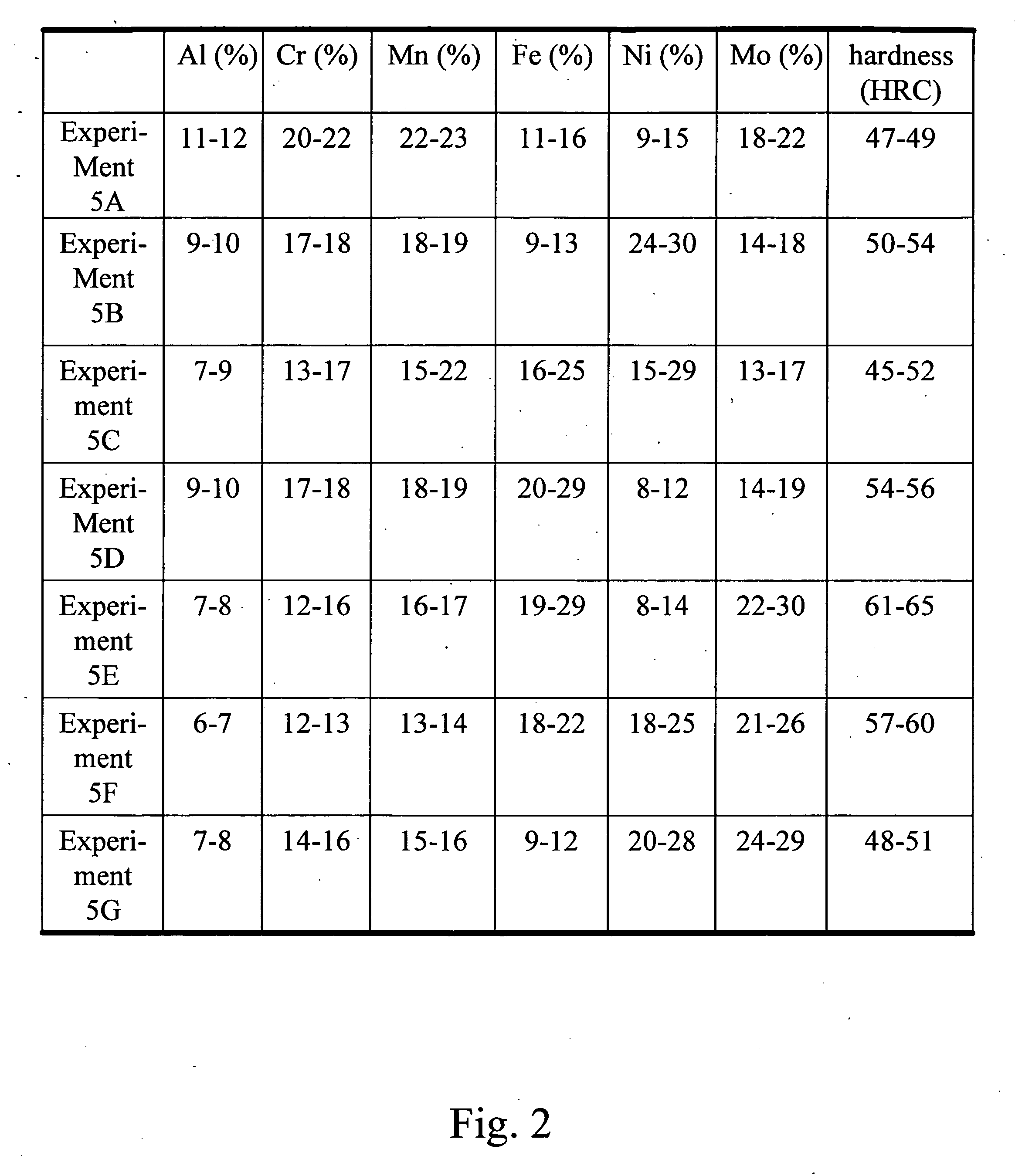

[0029] The present invention provides a multi metal base hardfacing alloy, which includes Fe, Ni, Cr, and Mn or Mo, wherein either Mn or Mo is selected. The atom percent of Fe is a % (5%≦a %≦35%), that of Ni is b % (5%≦b %≦35%), that of Cr is c % (5%≦c %≦35%), and that of Mn or Mo is d % (5%≦d %≦35%) in the alloy, wherein a %+b %+c %+d %≦100%.

[0030] Al (aluminum) is added into the above-mentioned multi metal base hardfacing alloy with an atom percent of e % in the alloy, wherein 2%≦e %≦12%, and a %+b %+c %+d %+e %≦100%. Co (cobalt) may also be added as required with an atom percent of f % in the alloy, wherein 17%≦f %≦21%, and a %+b %+c %+d %+f %≦100%. Moreover, the multi metal base hardfacing alloy of the present invention does not contain the specific elements su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com