Display device

a display device and rear cover technology, applied in the field of display devices, can solve the problems of inability to properly mount the lcd device, easy etc., and achieve the effect of minimizing the deformation of the rear cover of the device during assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

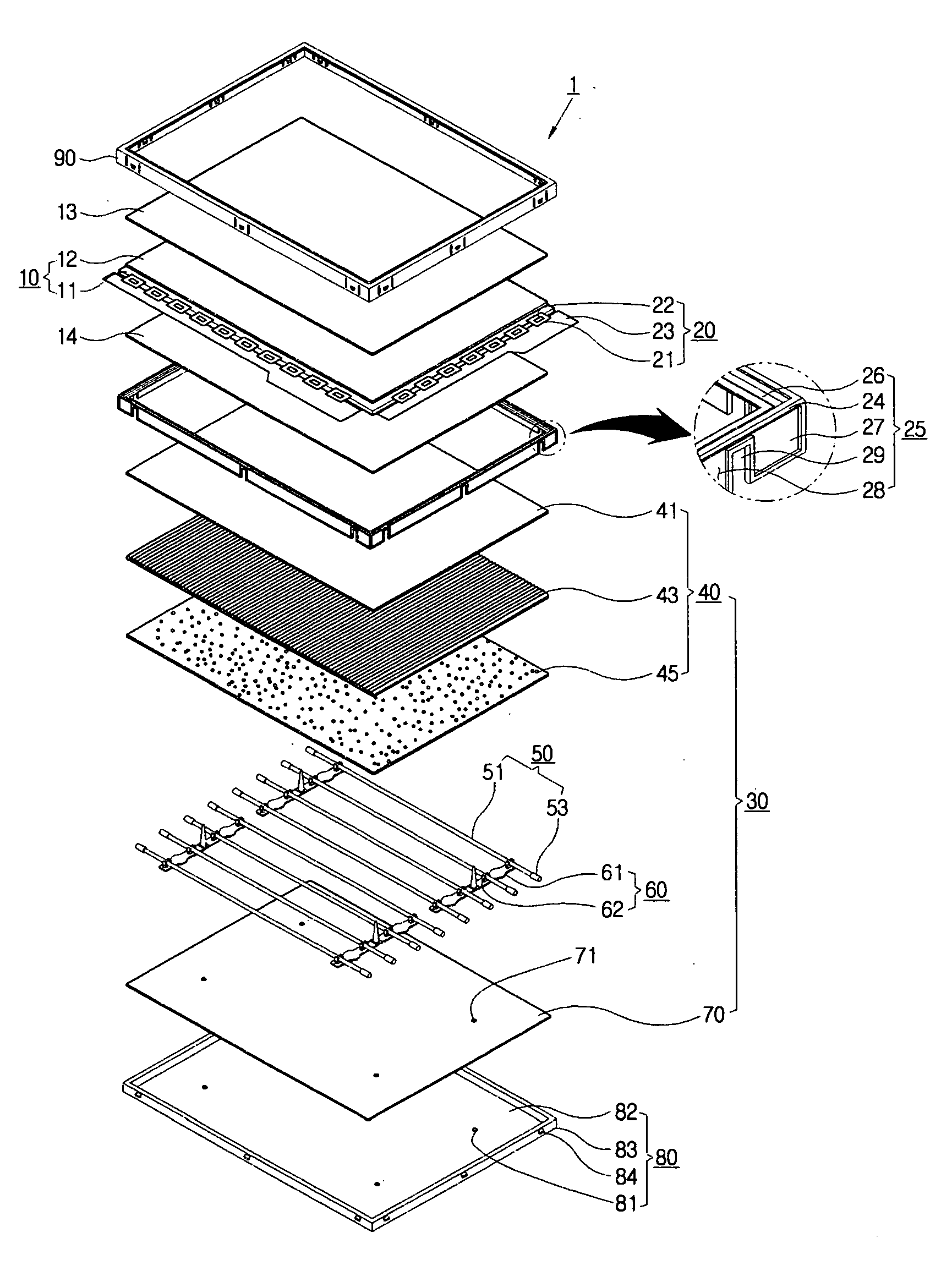

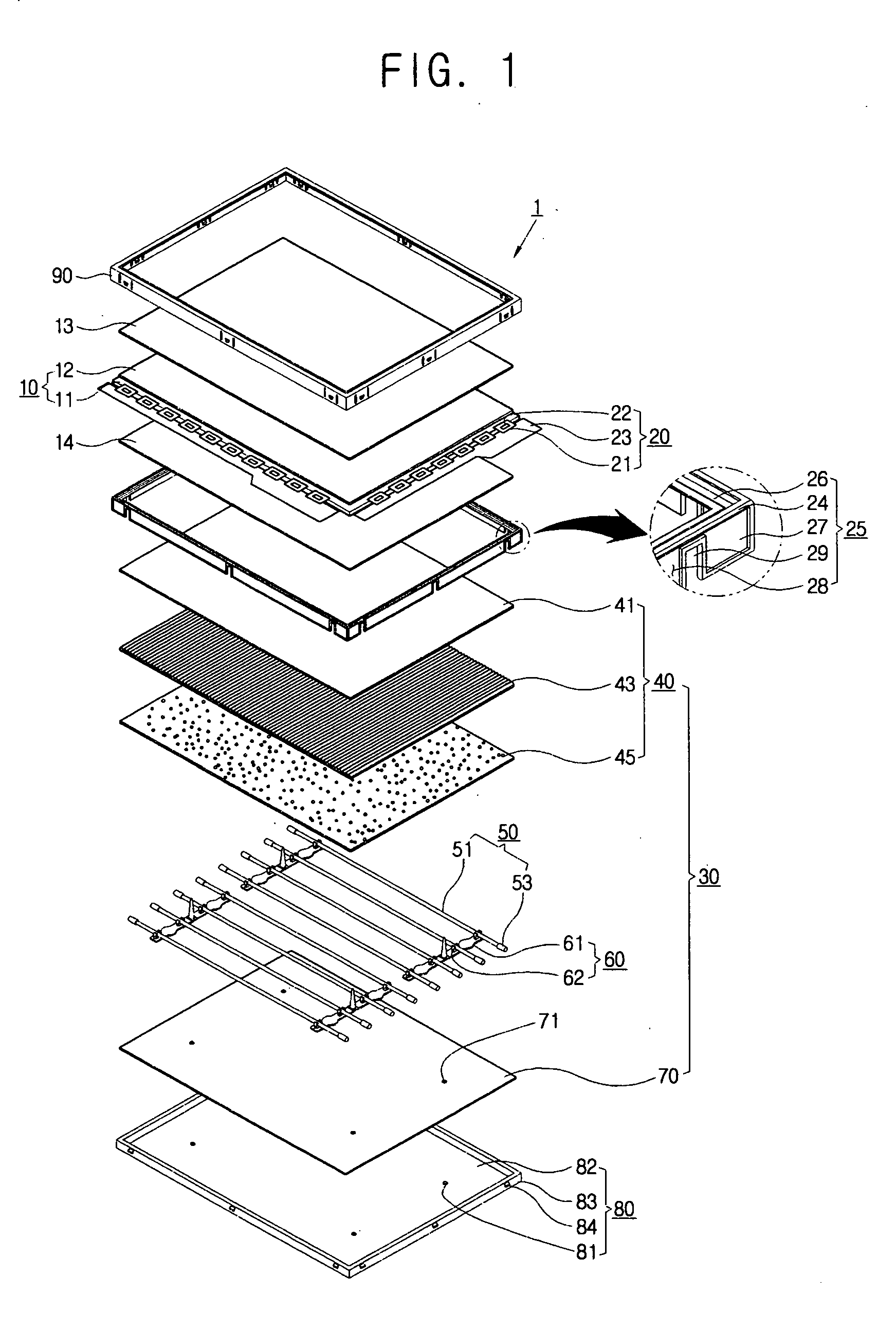

[0054] With the foregoing configuration in mind, a method for assembling the display device 1 according to the present invention of FIG. 1 is described below in conjunction with FIGS. 3 to 5B.

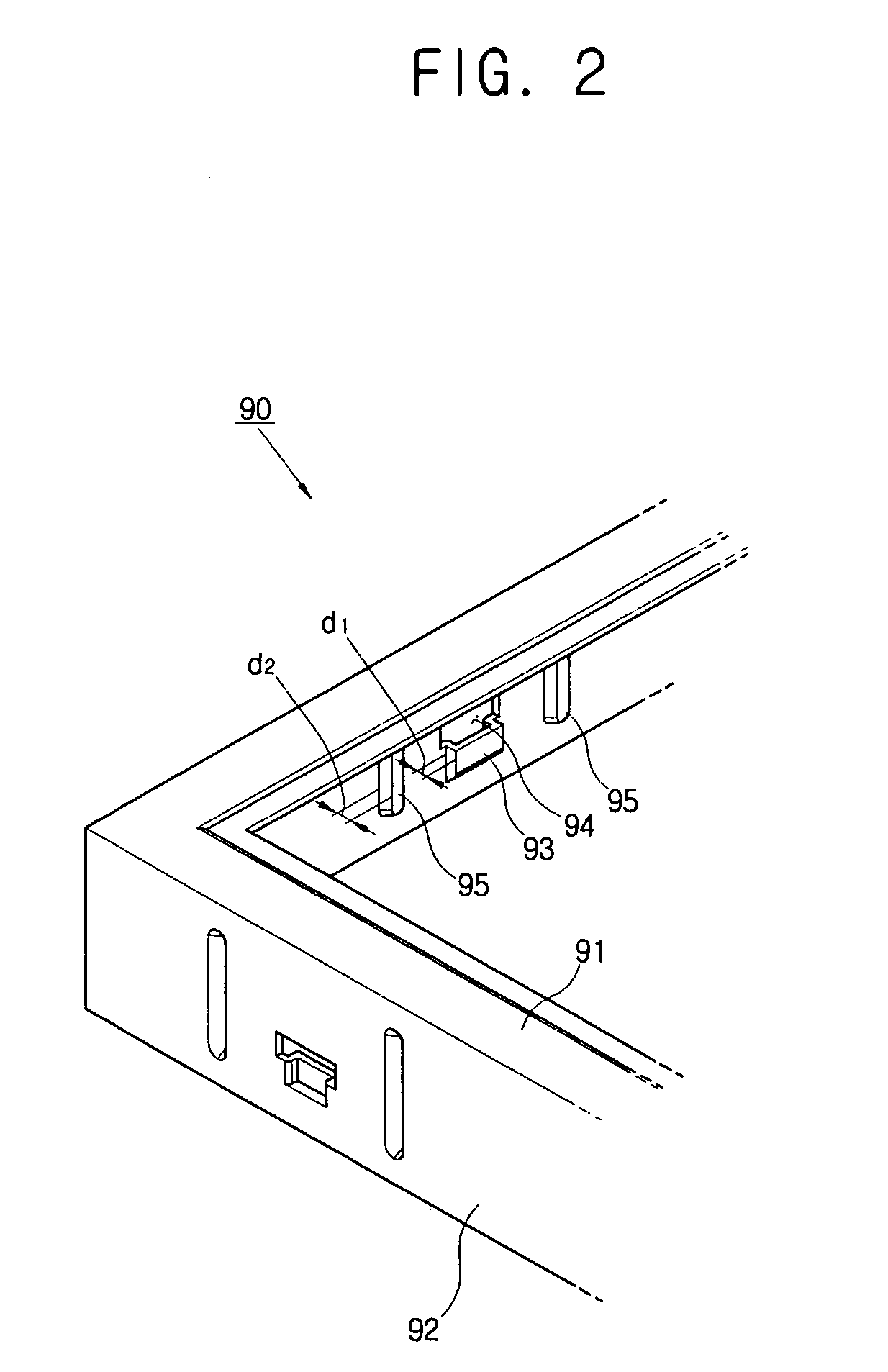

[0055] As illustrated in FIG. 3, the front cover 90 is pressed down over the mold frame 25 and rear cover 80. As discussed above, the distance from the rear ends of the elongated protrusions 95 to the bottom surface of the bottom plate 82 of the rear cover 80 is less than that from the front end of the front cover coupling part 93 to the bottom surface of the rear cover bottom plate 82. Thus, the rear ends of the elongated protrusions 95 contact the front cover lateral projection 24 first during the assembly of the front cover 90 onto the rear cover.

[0056] As illustrated in FIG. 4A, the inclined ramp face contacting surface “b” on the rear end of the elongated protrusion 95 slidably contacts the inclined ramp face contact surface “a” of the front edge of the lateral projection 24. As illustrat...

second embodiment

[0060] Following is a detailed description of the assembly of display device. As shown in FIG. 6A, when the front cover 90 is initially pressed down onto the rear cover 80, the front cover lateral part 92 slidably contacts the mold frame lateral projection 24. As illustrated in FIGS. 6A and 6C, the lateral distance d4 from the rear cover lateral wall 83 to the outer end of the projection 24 is larger than the lateral distance d5 (FIG. 6C), and accordingly, the front cover coupling parts 93 are disposed concentrically with respect to the rear cover coupling parts 84 and spaced laterally apart from them at a selected distance d3, as illustrated in the detail breakout view of FIG. 6C. That is, the front cover coupling parts 93 are disposed concentrically about and spaced apart from the rear cover coupling parts 84 by the mold frame lateral projection 24 during the assembly of the front cover to the rear cover. Thus, the rear cover 80 receives less pressure while being coupled with the ...

third embodiment

[0062]FIGS. 7A to 7D respectively illustrate a third exemplary embodiment of a display device in accordance with the present invention. With reference to these figures, a front cover coupling part 93 of the third embodiment protrudes laterally outward from a front cover lateral part 92. As illustrated in FIGS. 7A and 7C, the sum of the lateral height d2 of an elongated inward protrusion 95 on an inner surface of the lateral part 92 of the front cover 90 and a lateral height d4 of a lateral projection 24 on the mold frame 25 from an outer surface of the lateral wall 83 of the rear cover 80 is greater than the lateral height d6 of a rear cover coupling part 84.

[0063] As illustrated in FIG. 7A, when the front cover 90 is pressed down over the mold frame 25 and rear cover 80, the protrusion 95 on the front cover slidably contacts the projection 24 first. As shown in FIGS. 7A and 7C, as the sum of the lateral height d2 of the inward protrusion 95 and the lateral height d4 of the lateral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com