Photo-sensor and pixel array with backside illumination and method of forming the photo-sensor

a photo-sensor and array technology, applied in the field of pixel sensors, can solve the problems of incident angle, cmos has not been particularly suited to efficient pixel design, and the difficulty of fabricating dense cmos image sensor arrays, and achieve the effect of maximizing image sensor signal reception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

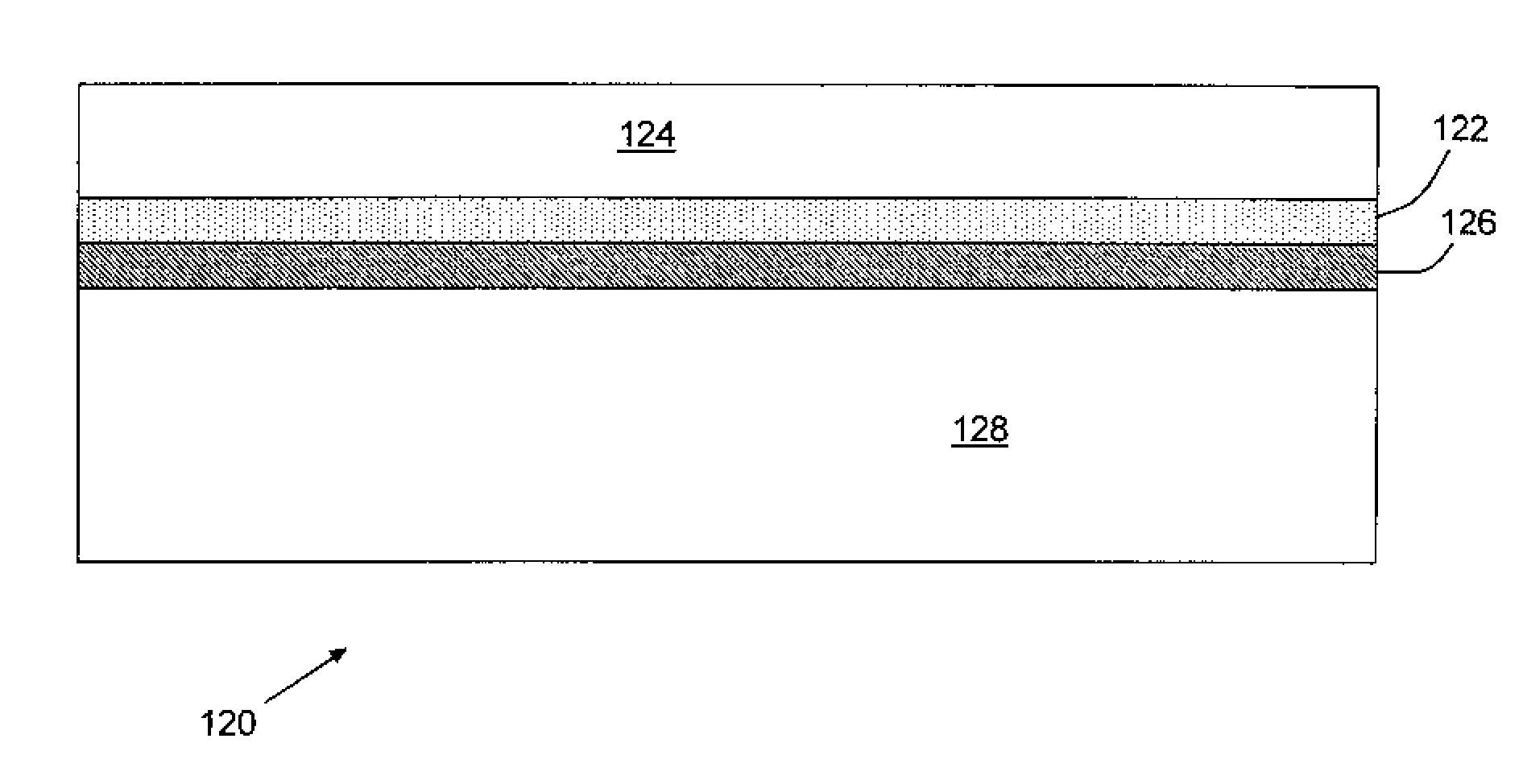

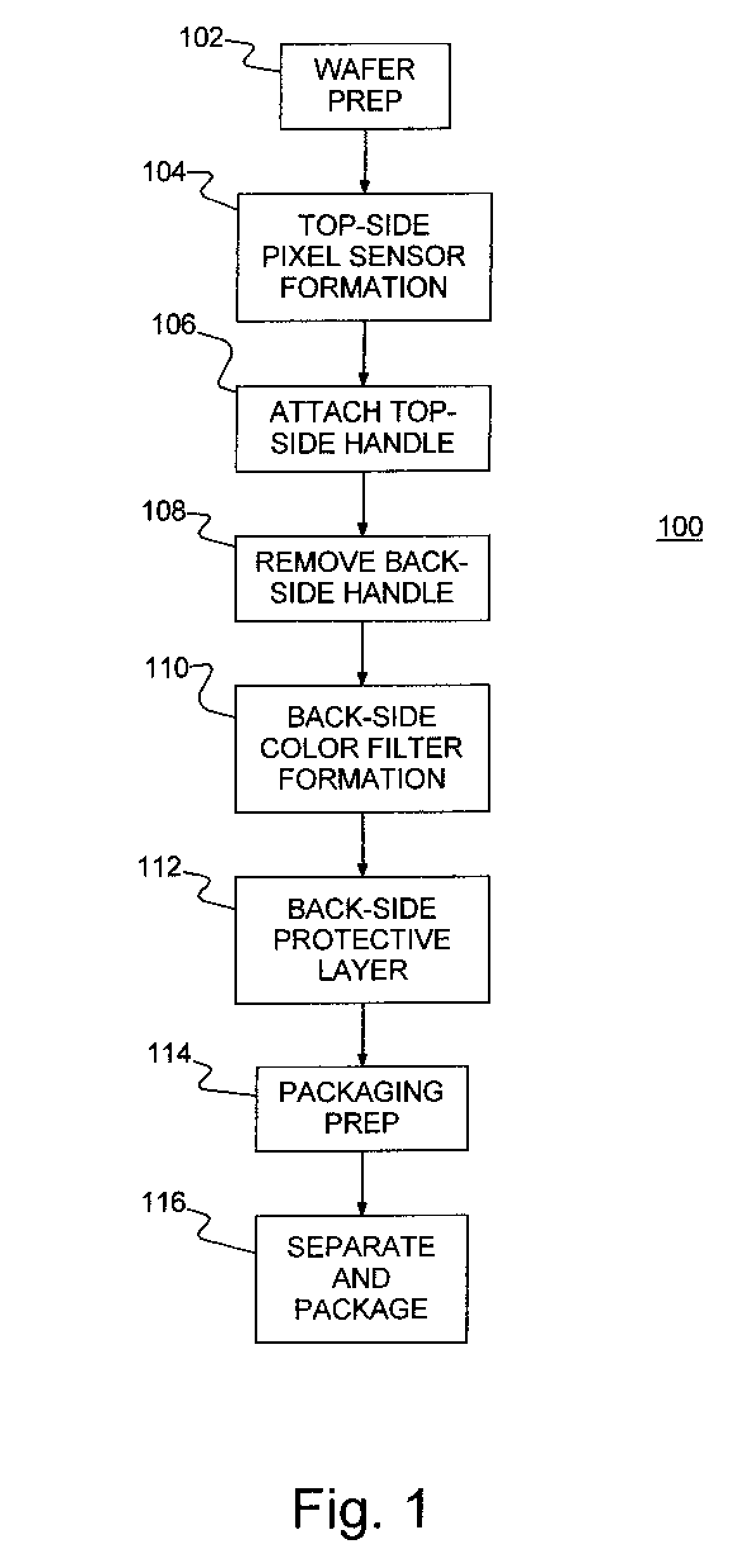

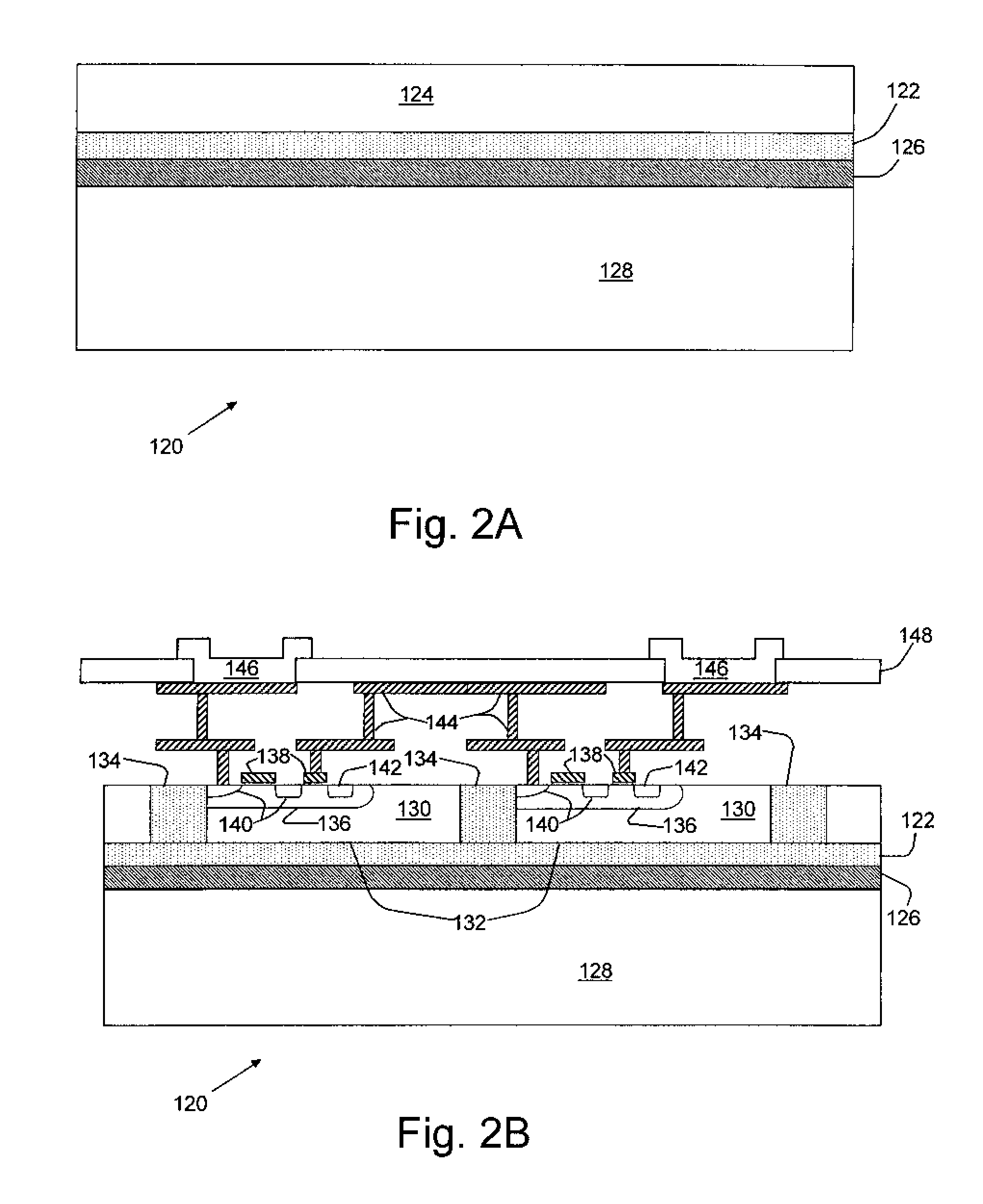

[0019] Turning now to the drawings, and more particularly, FIG. 1 shows an example 100 of forming an imaging sensor according to a preferred embodiment of the present invention. Sensor formation begins in step 102 by preparing a semiconductor wafer, e.g., by forming a dielectric layer, such as thermal oxide, on the surface of a silicon wafer. A bonding layer (e.g., nitride) is formed on the dielectric layer and a first handle wafer is bonded to the bonding layer. In step 104 image pixel sensors are formed on the exposed side of the silicon wafer, preferably, coincident with normal circuit formation. Preferably, chip circuits are formed in the insulated gate Field Effect Transistor (FET) technology commonly known as CMOS. Further, although described herein with respect to CMOS, the present invention has application to forming pixel arrays in any FET technology.

[0020] Chip circuit formation proceeds through inter-circuit wiring and, preferably to off-chip connections, i.e., in what i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com