Rigid axle with integrated spring brackets for use on a vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

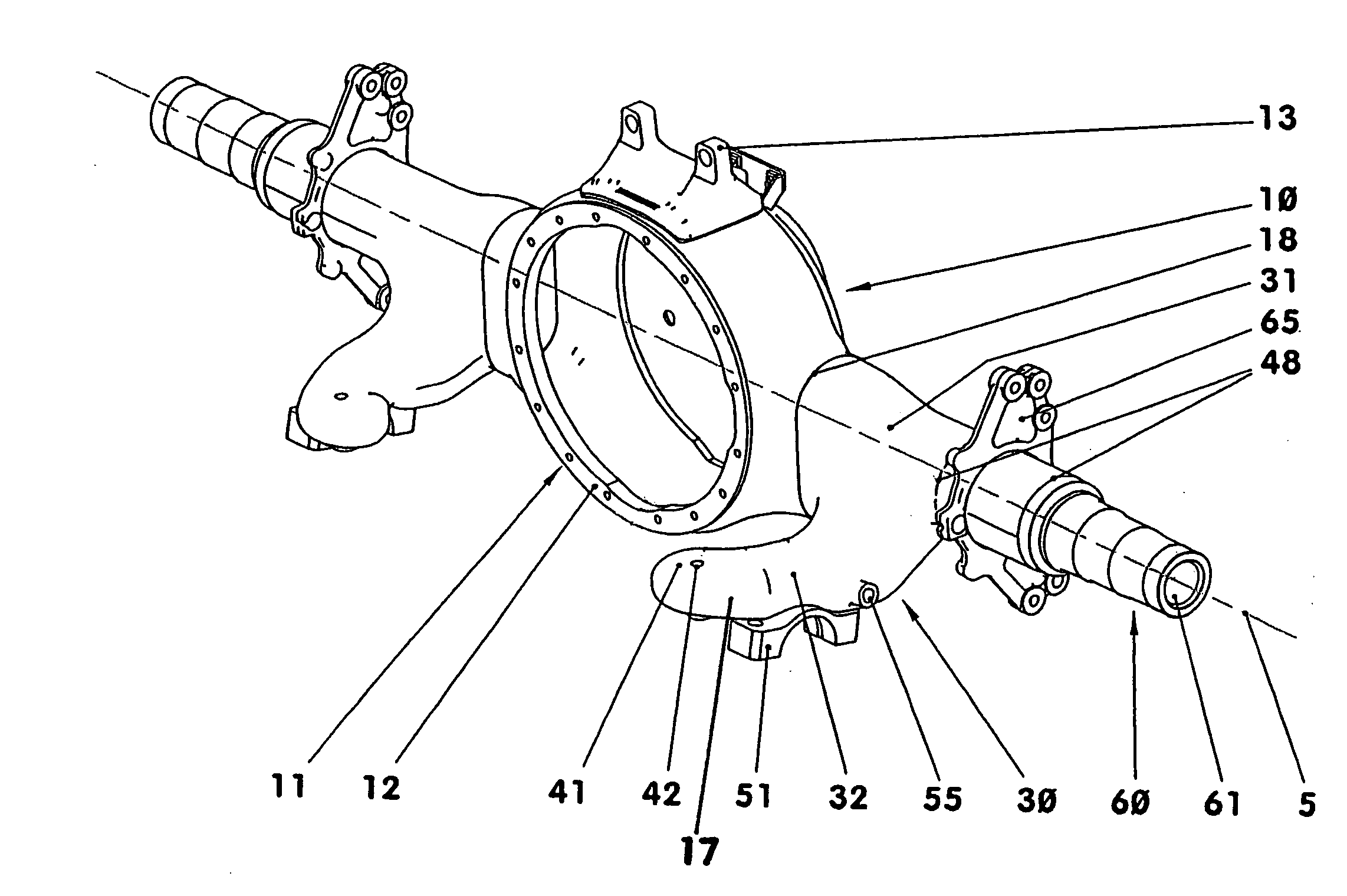

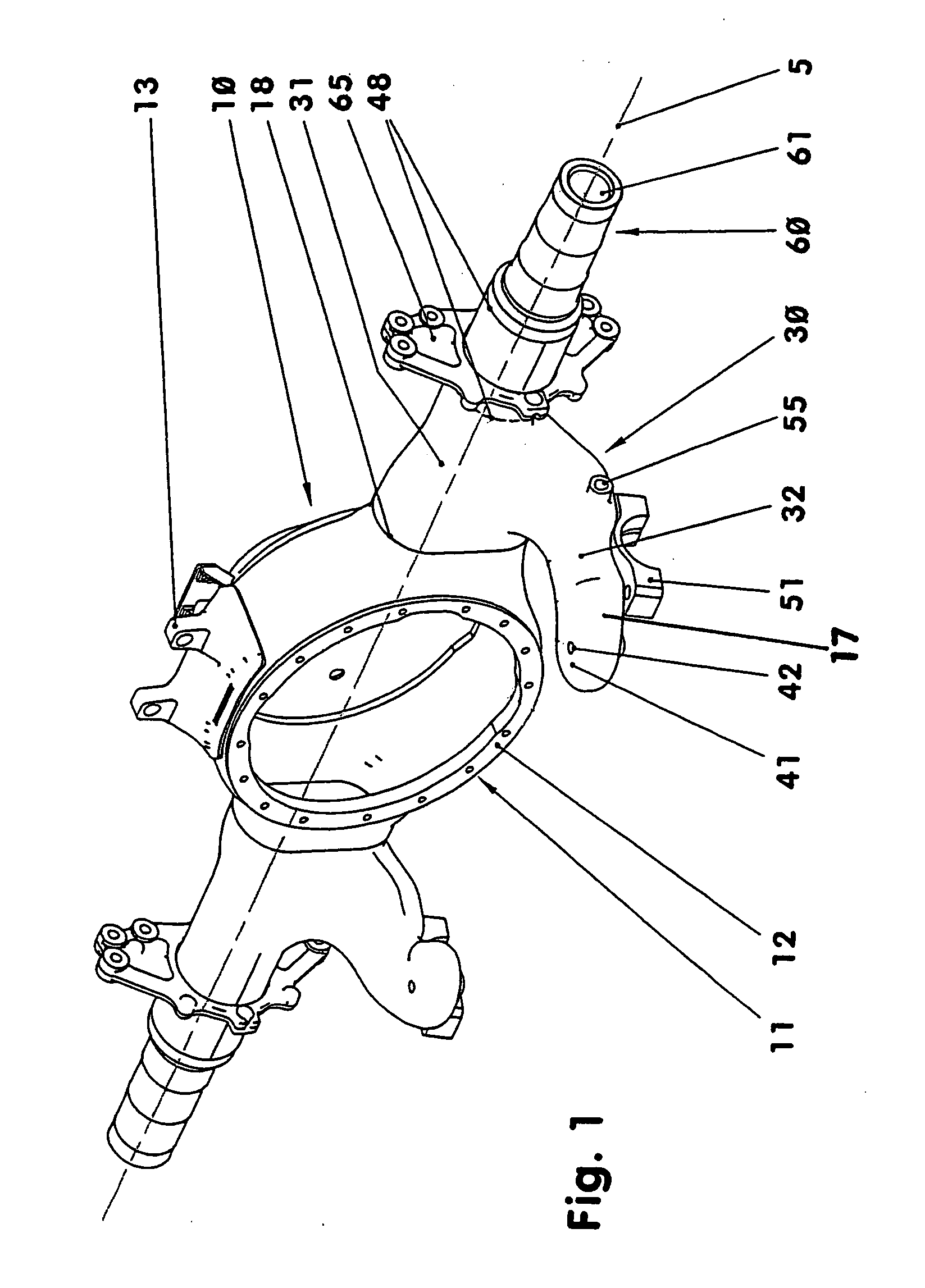

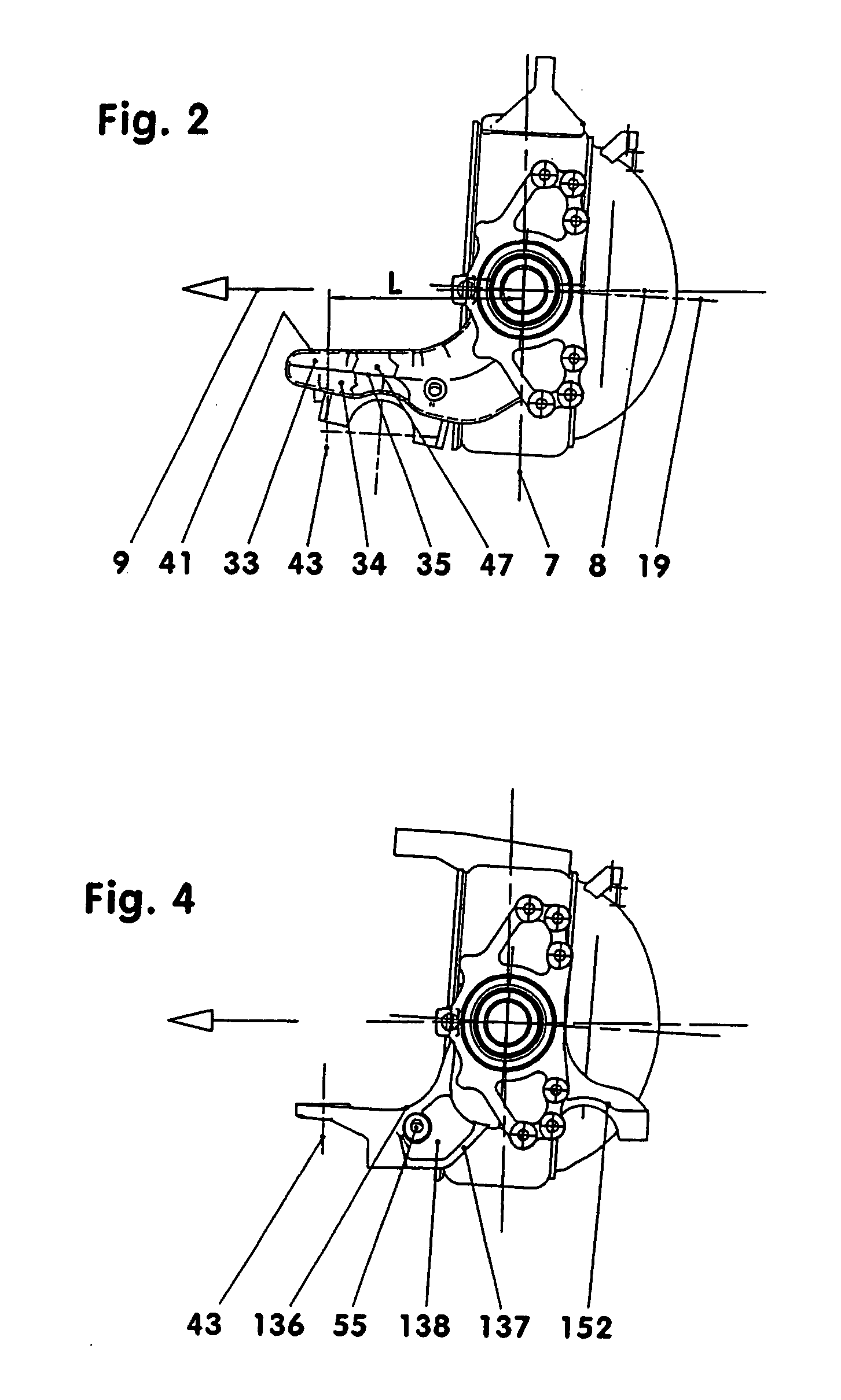

[0018] FIGS. 1 to 4 show examples of two different axle beams (10, 110), which may in each case be driven rigid axles of a commercial vehicle. Such an axle may also be a steered axle.

[0019] The axle beam (10) as shown in FIG. 1 comprises a center structure (12) including a differential housing (11), opposite axle tube sections 31 with spring brackets (30) and two axle journals (61) forming the outer axle beam end sections (60).

[0020] The differential housing (11), may be formed from sheet metal and form the center part of the axle beam (10). As shown in the figures it is provided with. A support bracket (13), which may be forged, for example. The axle beam (10) is supported via a wishbone (not shown) on the vehicle frame by way of this support bracket (13). At either side, the differential housing (10) has a large opening of rectangular cross section, for example. The corners of these cross sections are rounded. At least 60% of the vertical portion of these virtually oval cross se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com