Catheter tubing with improved stress-strain characteristics

a catheter and strain-strain technology, applied in the field of catheters, can solve the problems of limiting both trackability and force transmission of catheters, and affecting the stability of catheters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

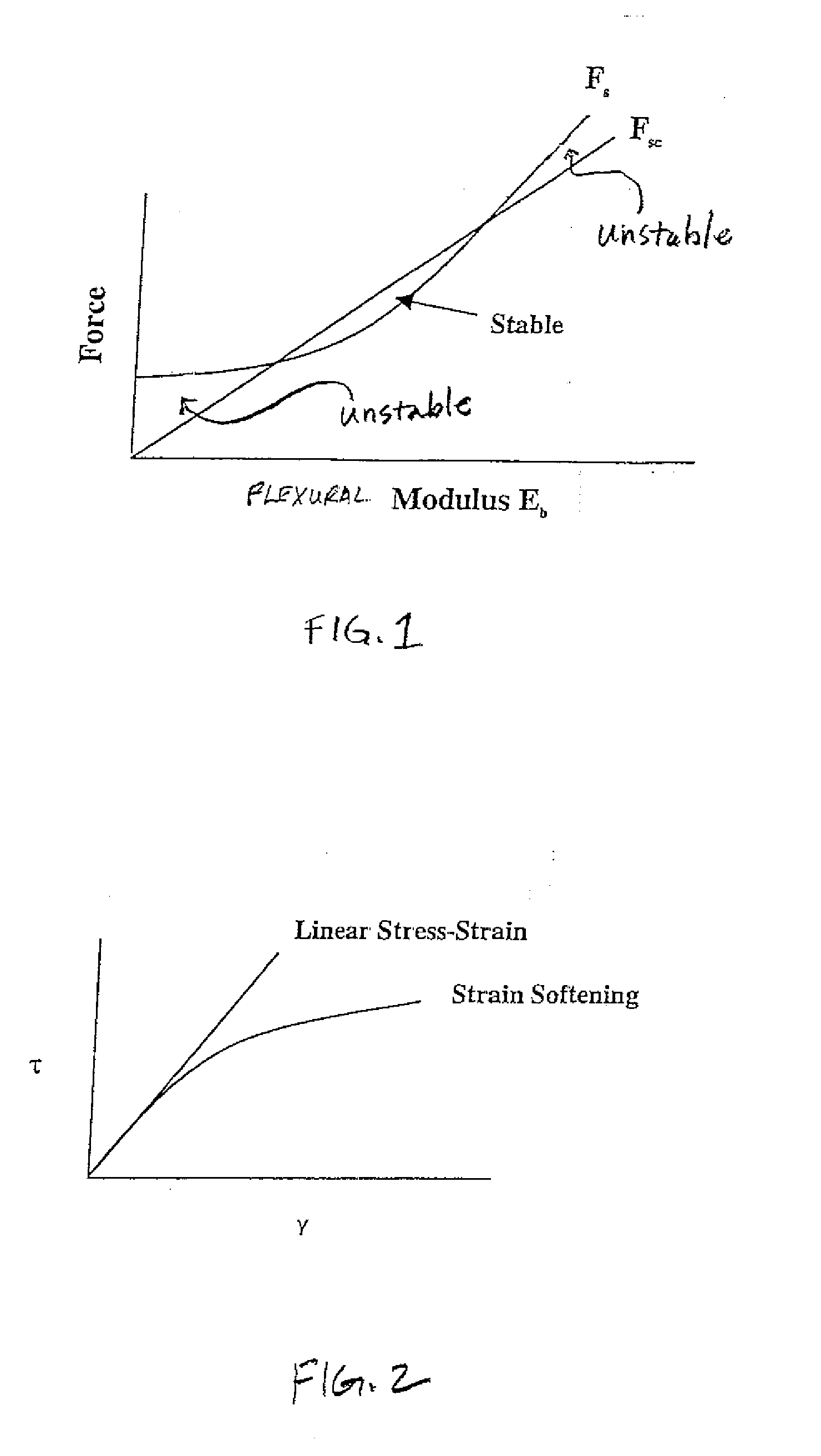

[0030] Specifically, flexural modulus (Eb) is the ratio of stress to strain within the elastic limit. A non-linear, strain softening structure can be broadly defined as a structure wherein the stress τ exhibits a decreasing dependence on strain γ. This is illustrated in FIG. 2 wherein the “strain softening” curve of the disclosed tubing represents a tubing that takes less force (Fs) to push the tubing through a tortuous path than the linear stress-strain tubing of the prior art.

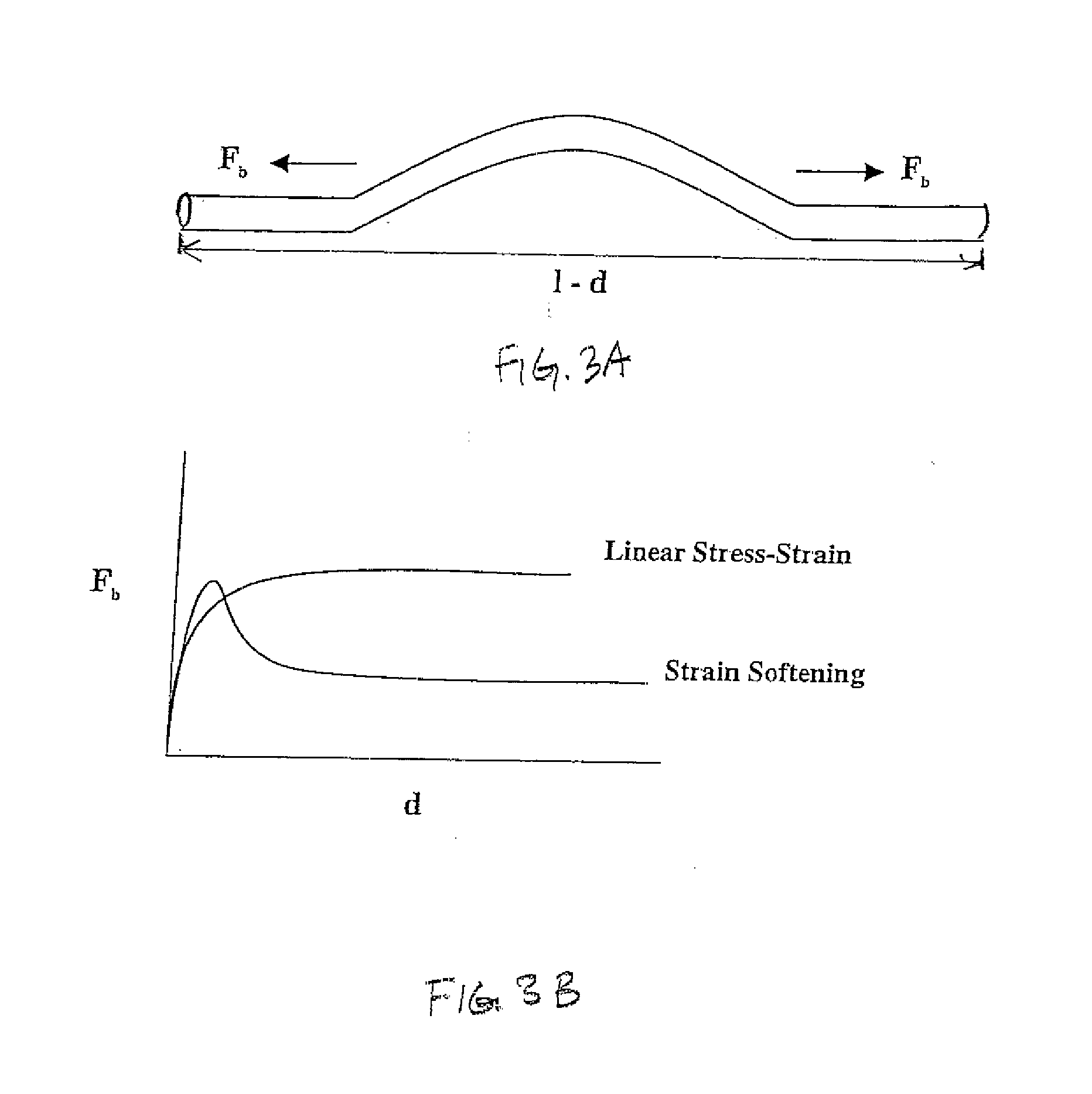

[0031] Furthermore, stress-strain properties have a large effect on the forces developed when a tubing sample traverses a tortuous path. For example, FIGS. 3A and 3B illustrate the forces that arise when a section of the tubing of length l undergoes a bending force Fb and is compressed or bent thereby reducing the length of the tubing by an amount d. Specifically, in FIG. 3A, the tubing of an overall length l has a reduced length l−d due to the bending shown in FIG. 3A. In FIG. 3B, as d approaches zero, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| break elongation | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com