Gas-permeable plug and method for manufacturing the same

a technology of gas-permeable plugs and gas-liquid injection, which is applied in the direction of sealing, electrical apparatus casings/cabinets/drawers, other domestic articles, etc., can solve the problems of affecting the adhesion performance and quality, and achieve the effect of raising the permeation resistance against gas and liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

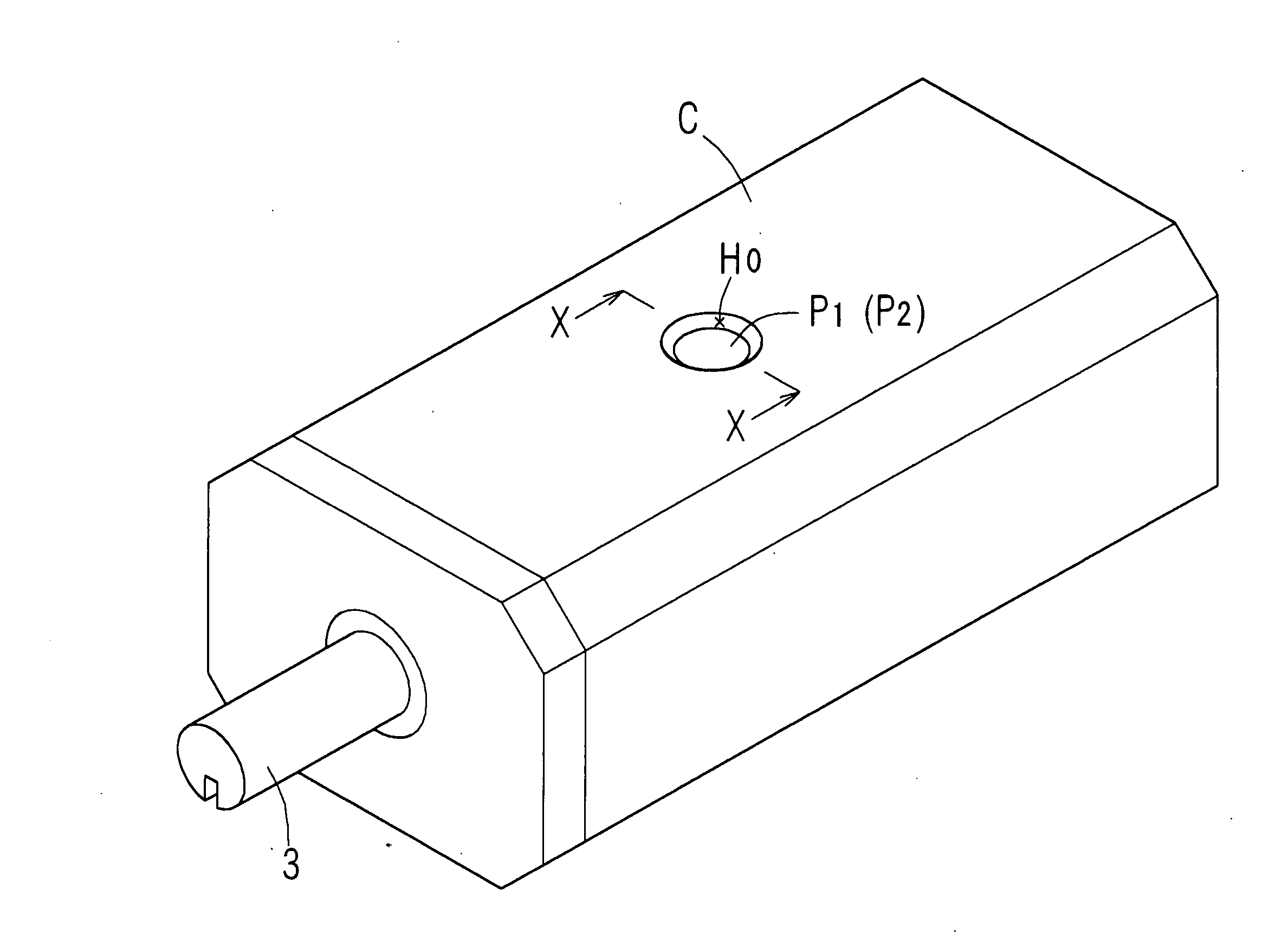

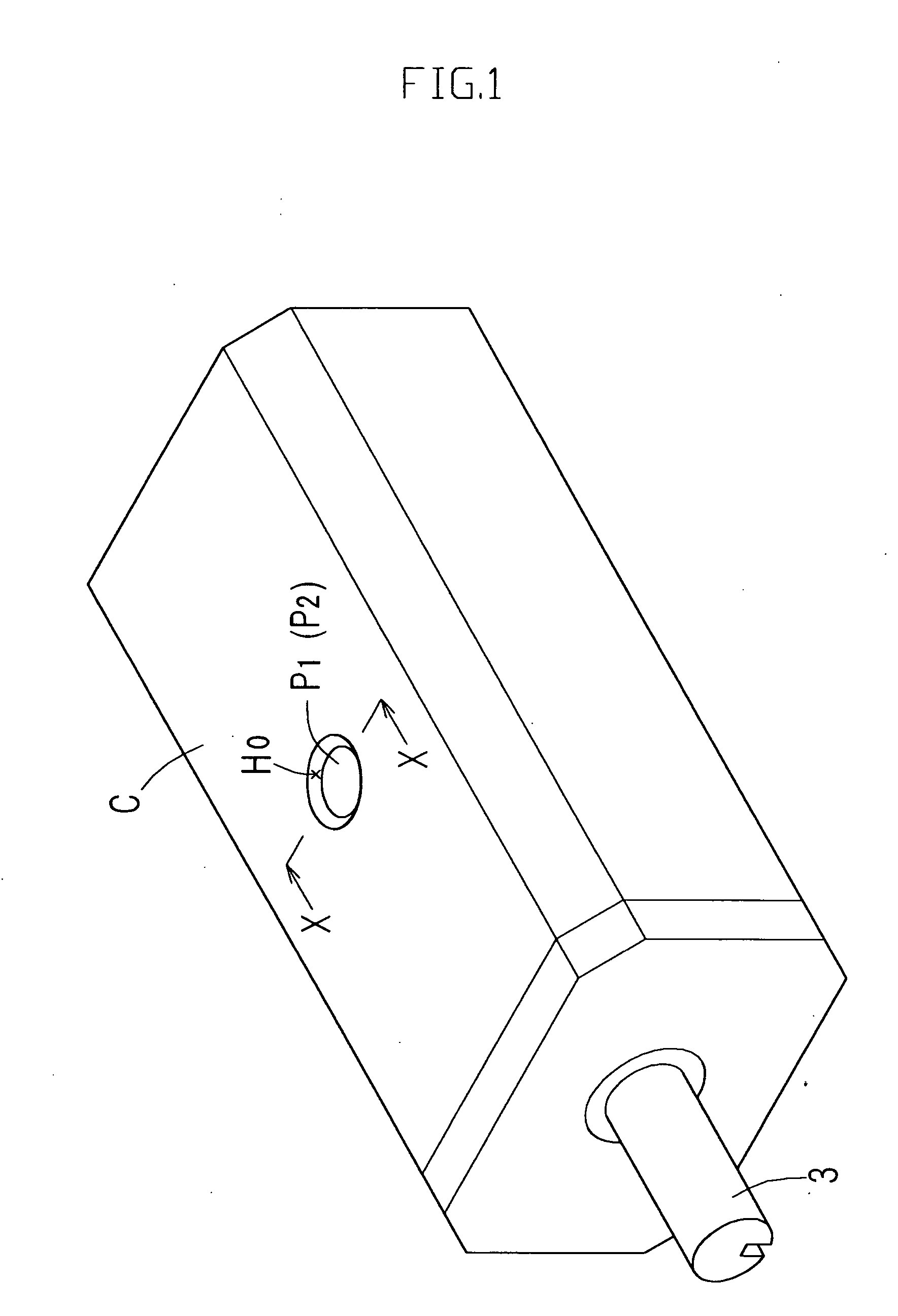

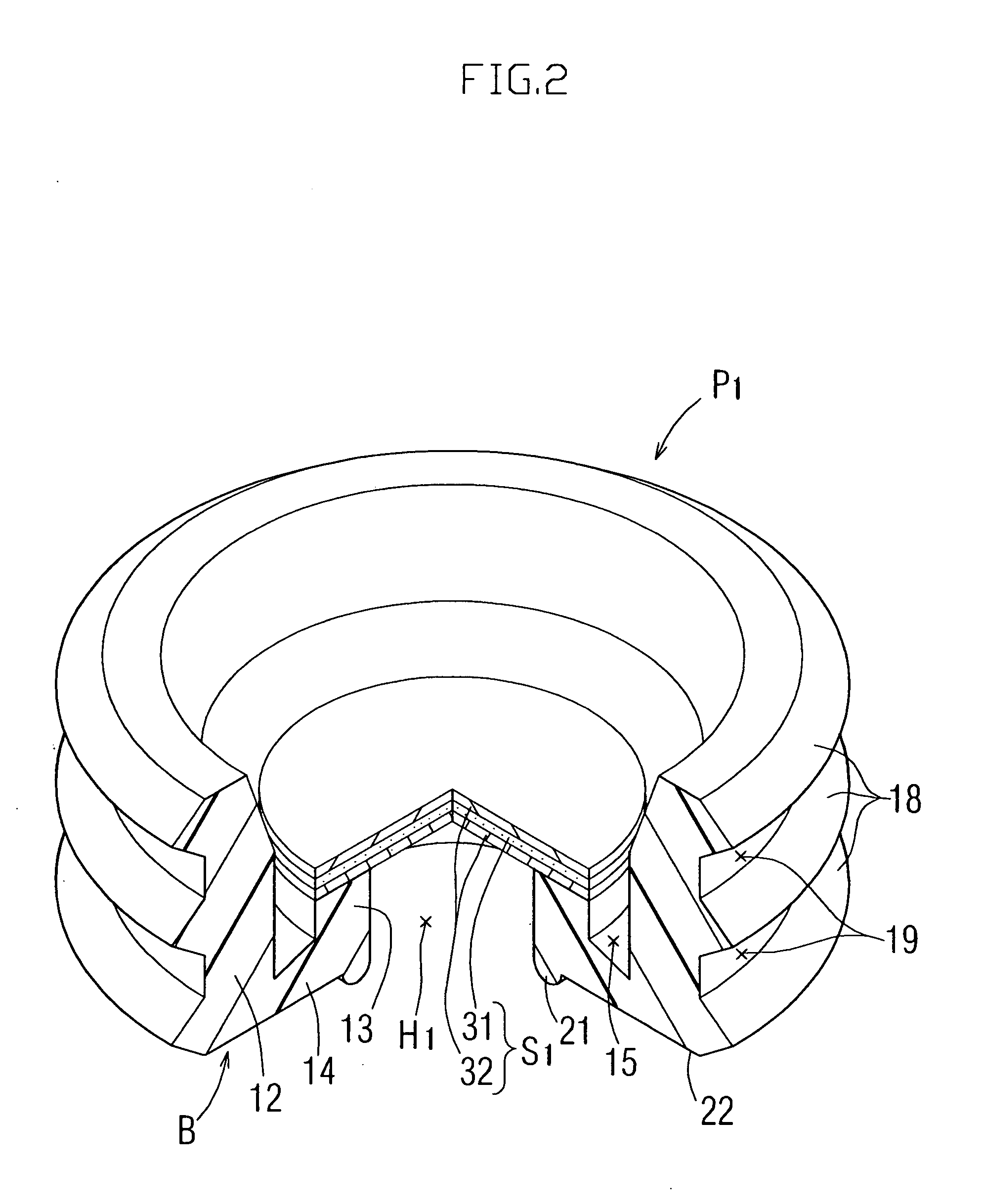

[0058] Hereinafter, the present invention will be described in more detail in relation to the embodiments. FIG. 1 is a perspective view of a state where a vehicle electric motor (not shown) is housed in a motor casing (hereinafter simply referred to as “casing”) C in which a gas-permeable plug P1 of a first embodiment of the invention is inserted. FIG. 2 is a perspective view in which a part of the gas-permeable plug P1 of the first embodiment of the invention is cut away, FIG. 3 is a sectional view showing a state before the gas-permeable plug P1 is inserted in an insertion hole H0 of the casing C. FIG. 4 is a sectional view (enlarged sectional view along line X-X of FIG. 1) after the insertion. Incidentally, in FIGS. 2, 3, 4 or the like, with respect to the illustration of a “permeable sheet”, since illustration of the actual size of the permeable sheet is impossible, the thickness is considerably enlarged in the illustration. As shown in FIGS. 1 to 4, in the casing C in which an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dwelling pressure | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com