External cavity laser

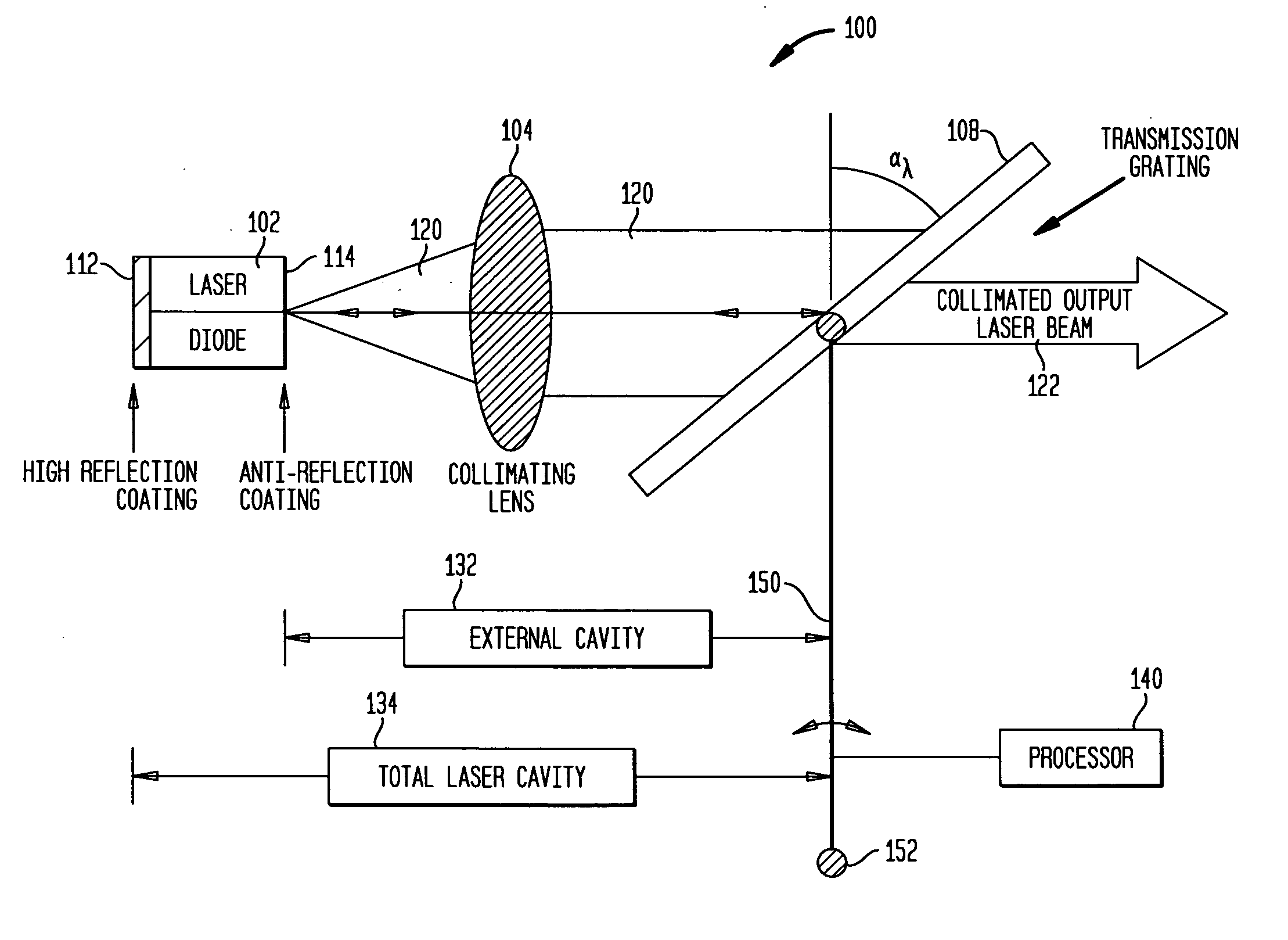

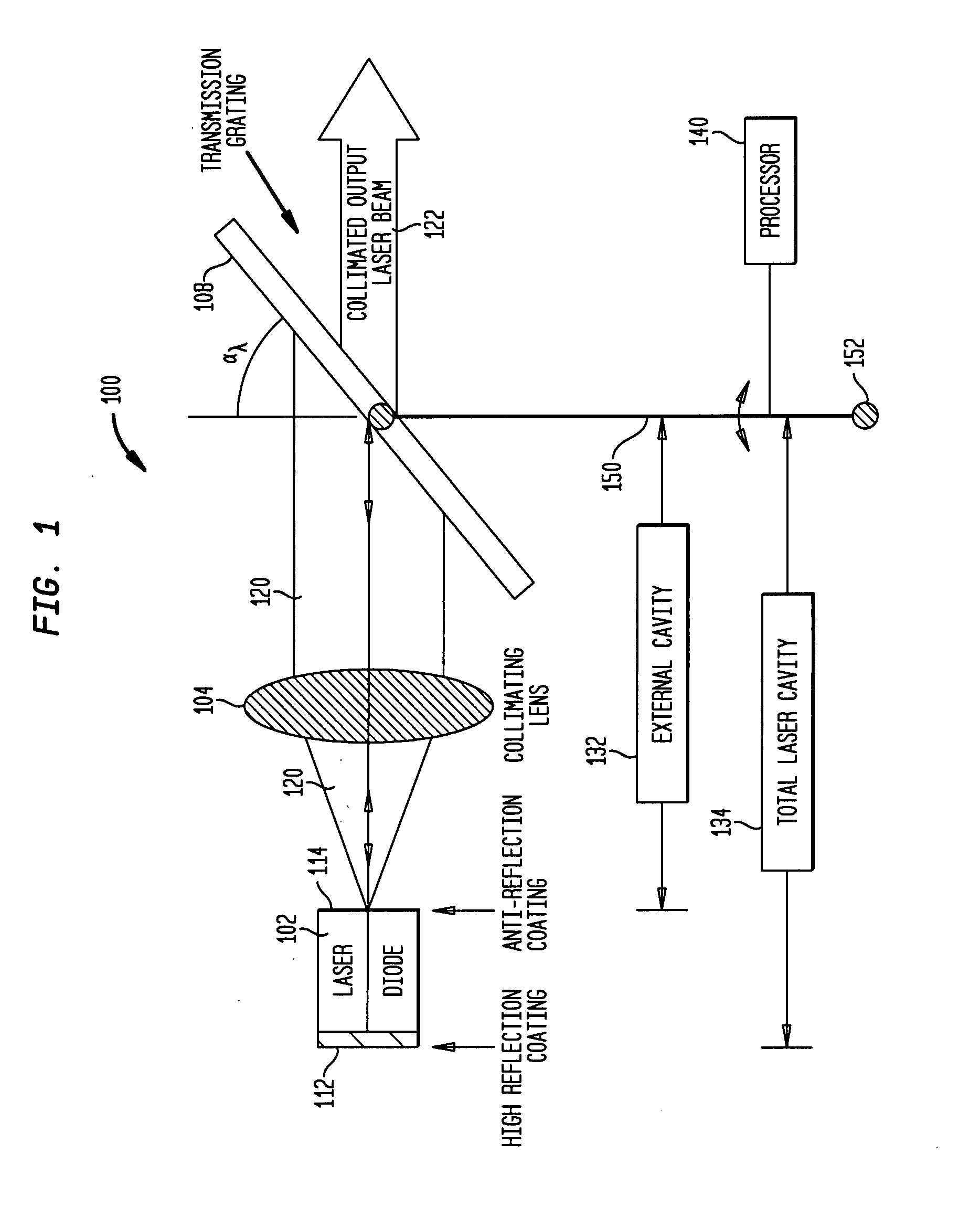

a laser and external cavity technology, applied in the field of external cavity lasers, can solve the problems of laser system instability, laser output hopping and other times of laser system hopping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

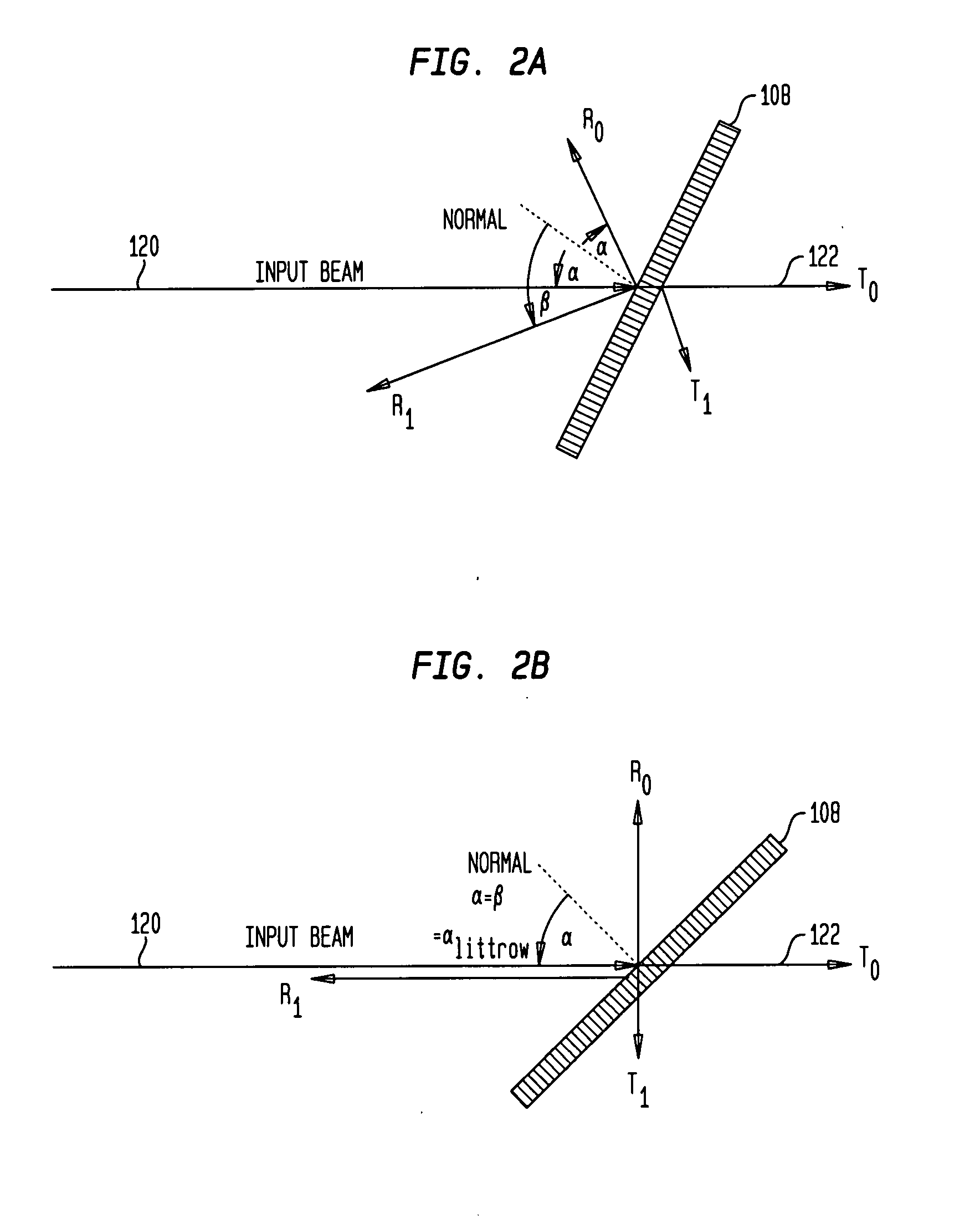

Embodiment Construction

[0030]It is advantageous to define several terms before describing the invention. It should be appreciated that the following definitions are used throughout this application.

Definitions

[0031]Where the definition of terms departs from the commonly used meaning of the term, applicant intends to utilize the definitions provided below, unless specifically indicated.

[0032]For the purposes of the present invention, the term “light source” refers to a source of electromagnetic radiation having a single wavelength or multiple wavelengths. The light source may be from a laser, a laser diode, one or more light emitting diodes (LEDs), etc.

[0033]For the purposes of the present invention, the term “coherent light beam” refers to a beam of light including waves with a particular (e.g., constant) phase relationship, such as, for example, a laser beam.

[0034]For the purposes of the present invention, the term “processor” refers to a device capable of executing instructions and / or implementing logic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com