Balanced Rotary Engine

a rotary engine and balanced technology, applied in the direction of positive displacement engines, engines with rotating cylinders, reciprocating piston engines, etc., can solve the problems of reducing the effective chamber, affecting the combustion process, and not being suitable for mixture use, so as to achieve the effect of favoring the dissipation of heat generated during combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

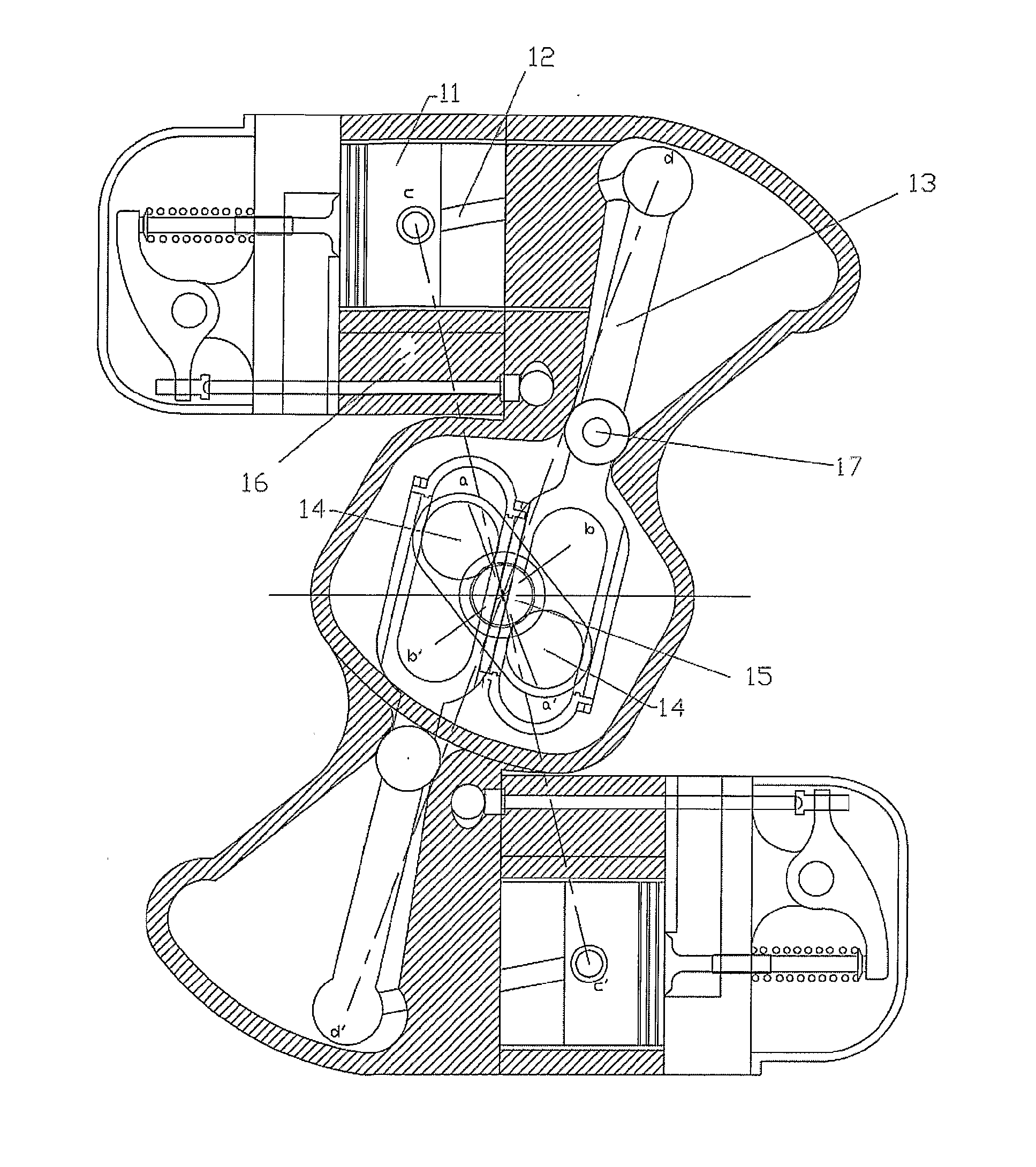

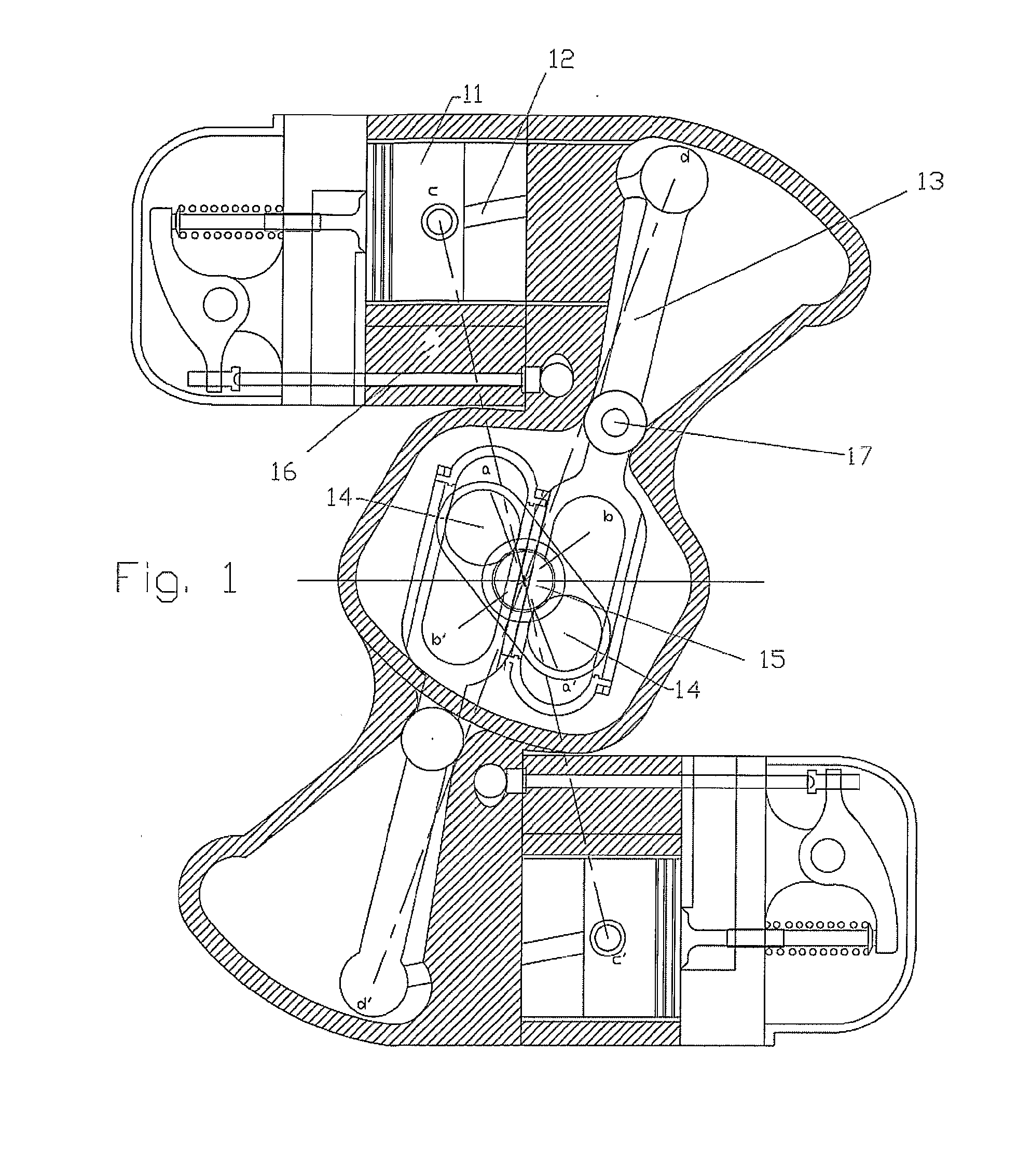

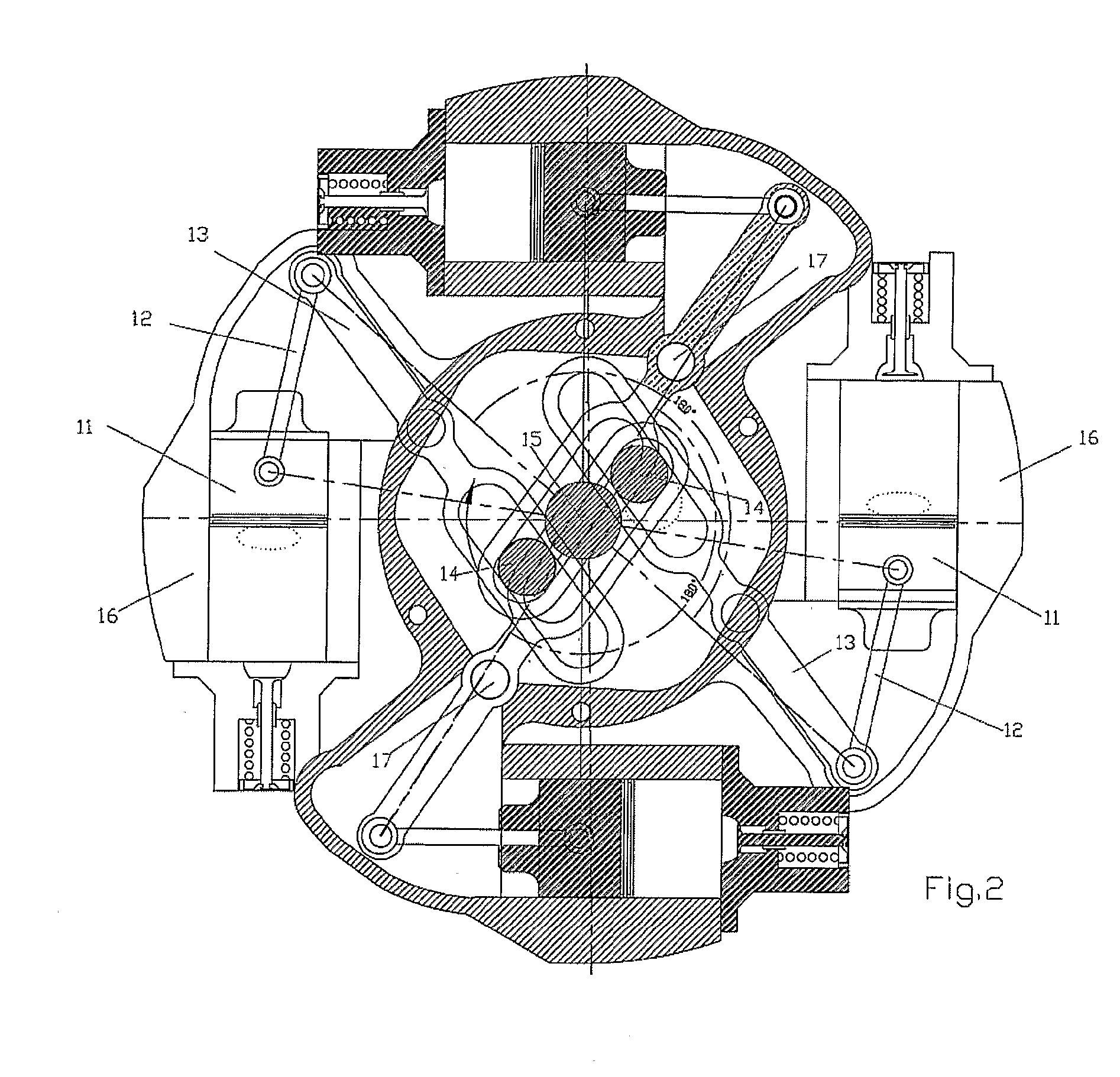

[0023] As can be seen in the attached drawings, there are two preferred embodiments for the balanced rotary engine. The first embodiment shows a balanced rotary engine (FIGS. 1, 2 and 3) whereas the second embodiment shows a self-powered balanced rotary engine (FIGS. 4, 5, 6, 7, 8, 9 and 10).

[0024] In the balanced rotary engine, the pistons (11) (FIGS. 1, 2 and 3) are coupled by means of their connecting rods (12) and the pivoted lever (13), to a gudgeon (14) of the crankshaft (15), which is shifted the same number of degrees ads the cylinders (16), thus obtaining in its linear alternative shifting during the rotation of the assembly (the block with these elements rotates in one direction and the crankshaft in the other) that they remain permanently balanced, either due to the opposite one or as a whole, in the case of an engine with an odd number of cylinders (FIG. 3). This arrangement allows coupling (FIG. 2) two pistons (11) to the same gudgeon (14) of the crankshaft (15) provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com