Quilted cold-weather garment with a substantially uncompressed interior foam layer

a quilted garment and interior foam technology, applied in the field of cold weather garments, can solve the problems of poor wind resistance and bulkiness, unattractive and bulky garments, lack of sufficient dexterity to perform routine movements, etc., to improve wind resistance, improve construction ease, and reduce material and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

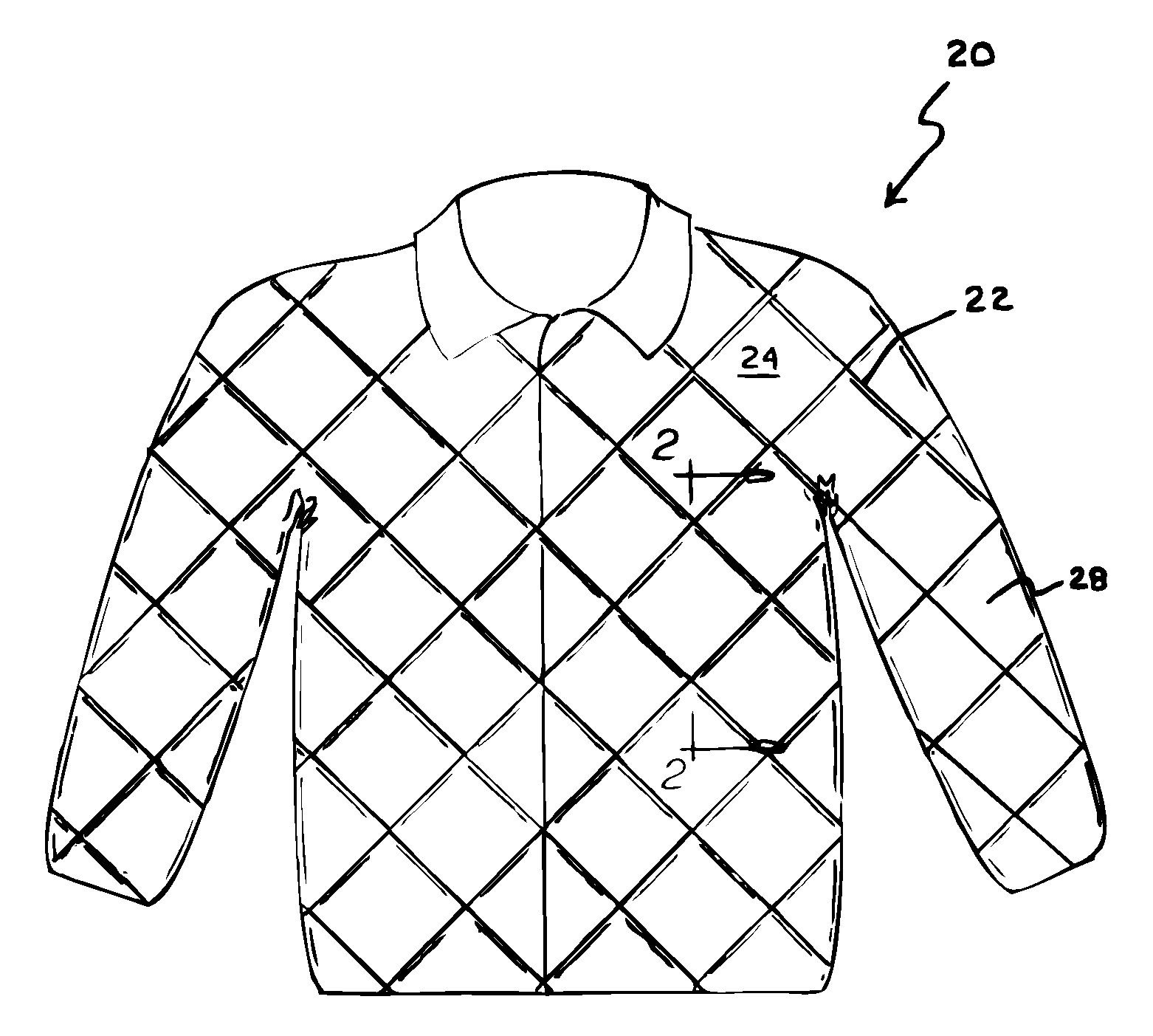

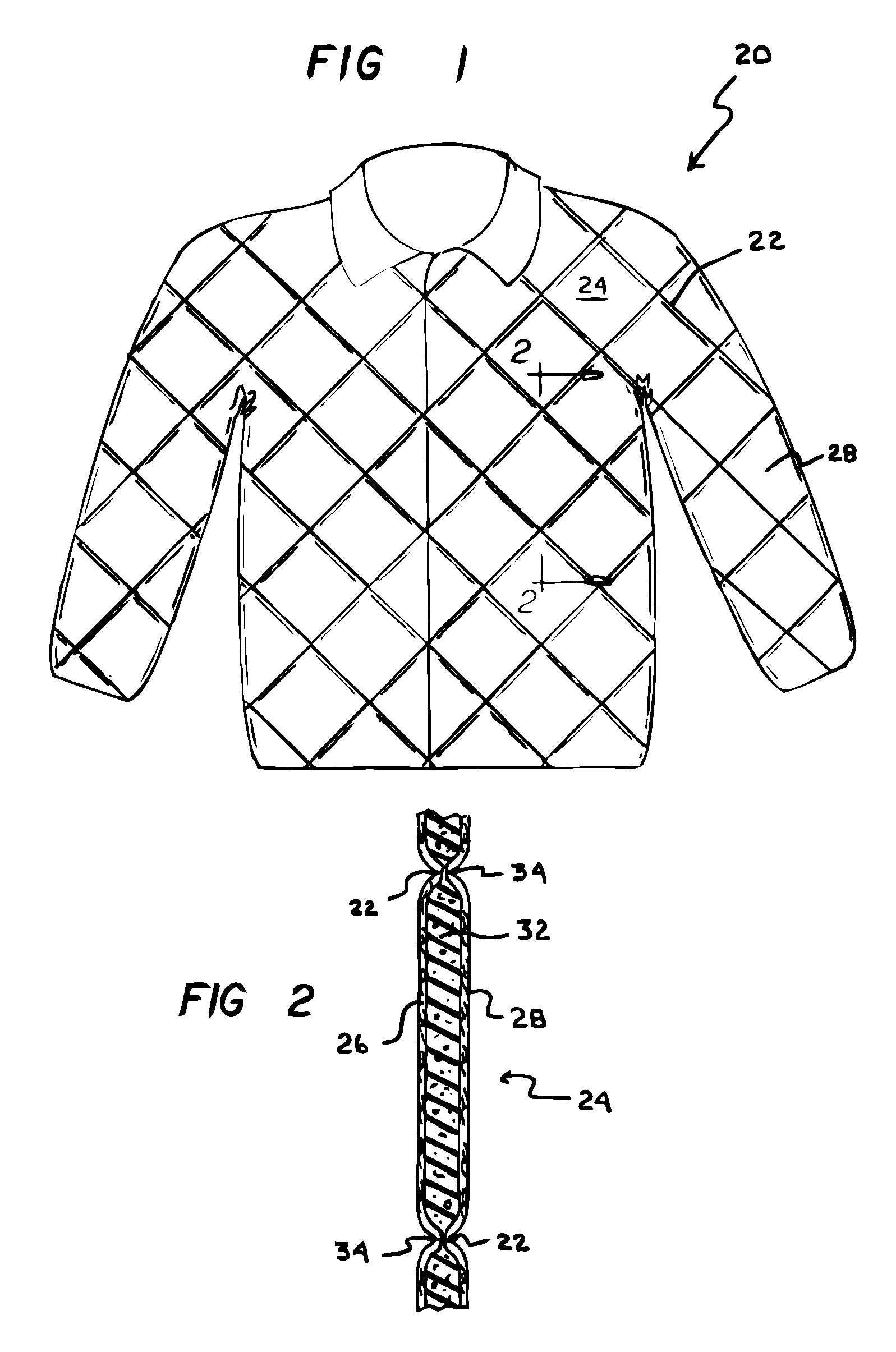

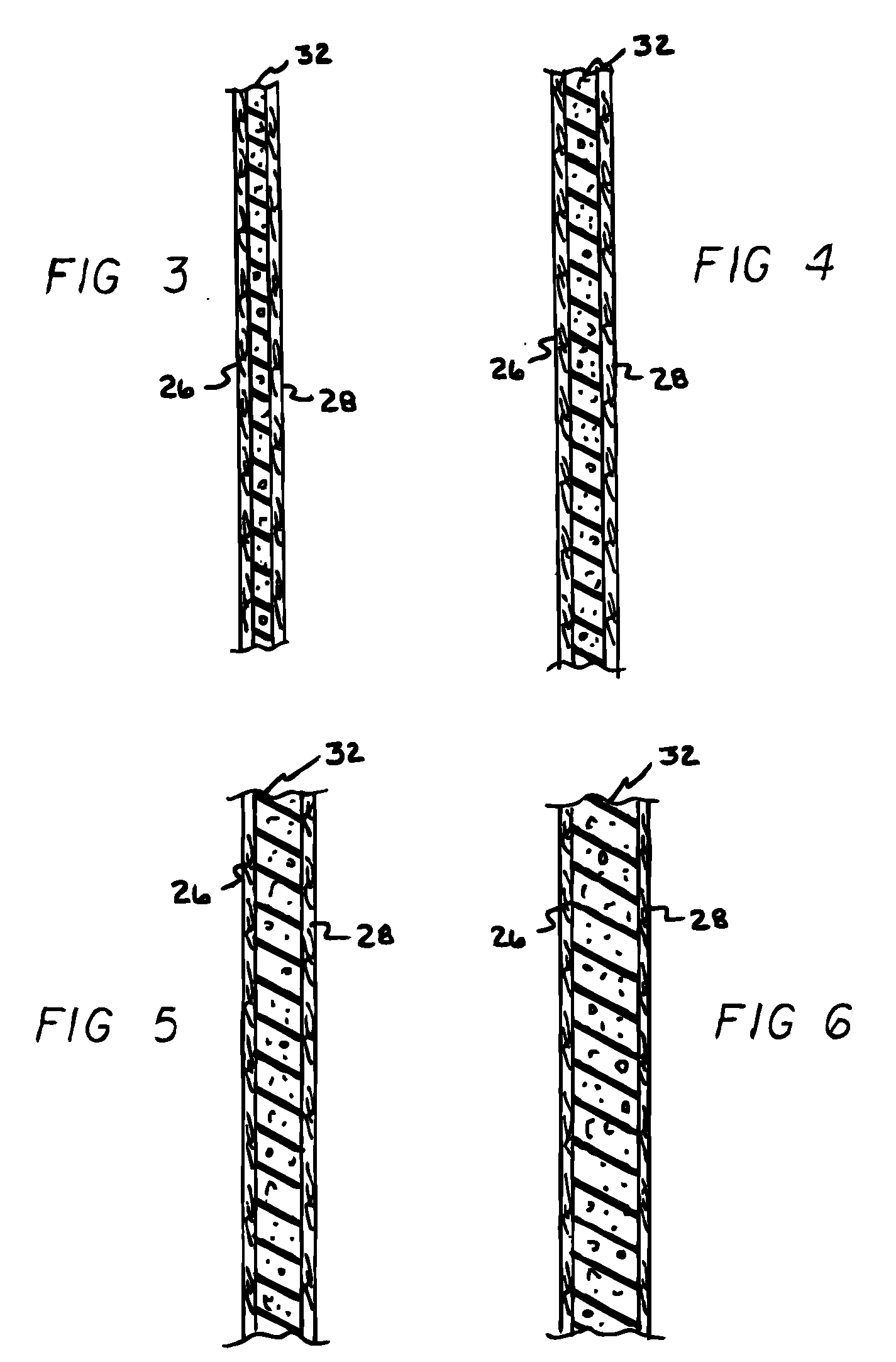

[0032] Referring to the Figures, in which like parts are indicated with the same reference numerals, various views of an exemplary quilted cold-weather garment constructed in accordance with the principles of the present invention are shown. The present invention relates to an improved cold weather garment construction. The construction uses two fabric layers positioned about an intermediate foam layer. To improve range of motion and reduce bulkiness, the three layers are quilted together and the foam is provided in varying thicknesses to match anticipated weather conditions. Additionally, the intermediate foam layer can have a skinned layer adjacent to the exterior layer and a convoluted surface opposite the interior layer. The various components of the present invention, and the manner in which they interrelate, will be described in greater detail hereinafter.

[0033] With reference now to FIG. 1, a cold weather garment constructed in accordance with the principles of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com