Heated glass panels and methods for making electrical contact with electro-conductive films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

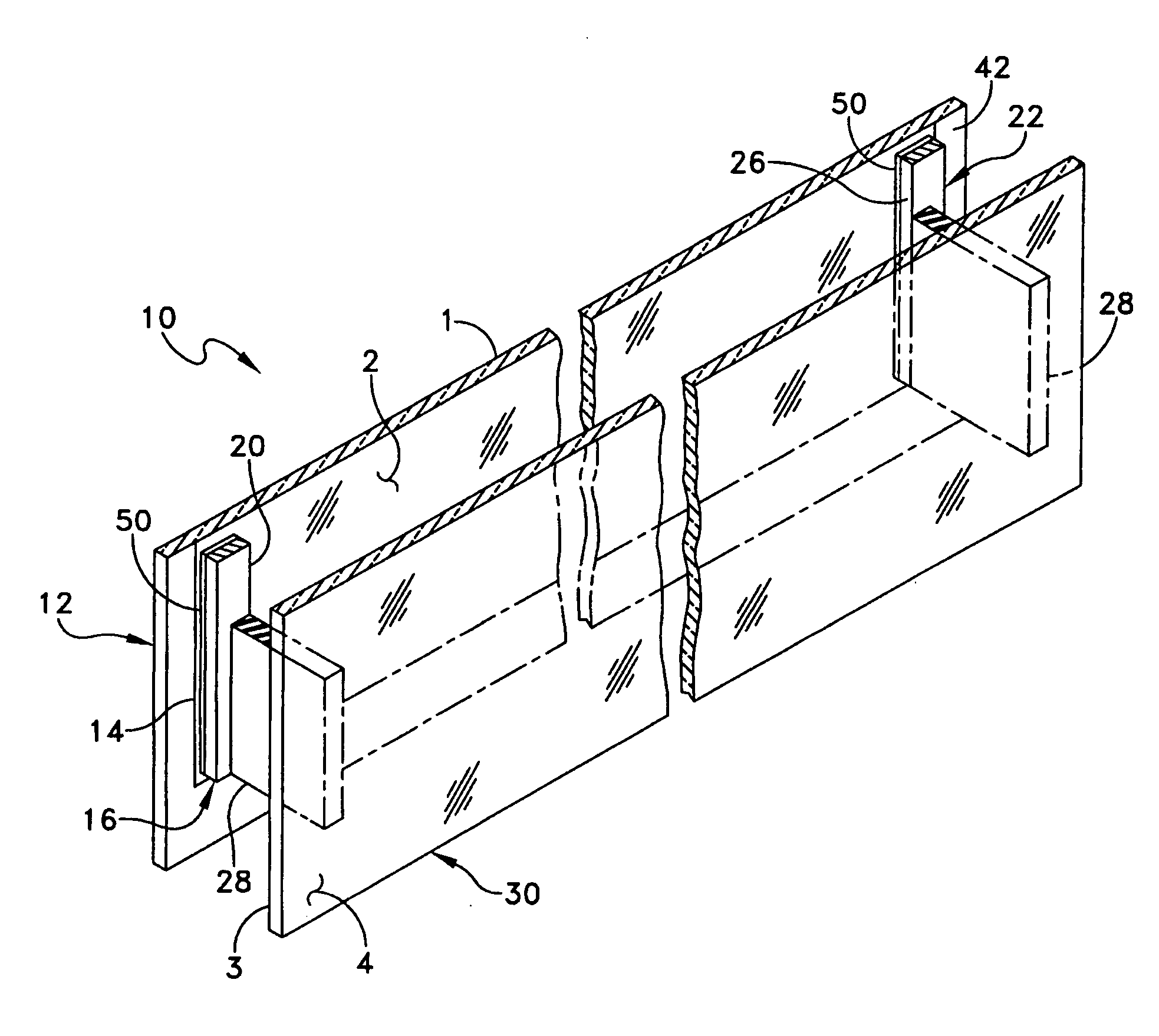

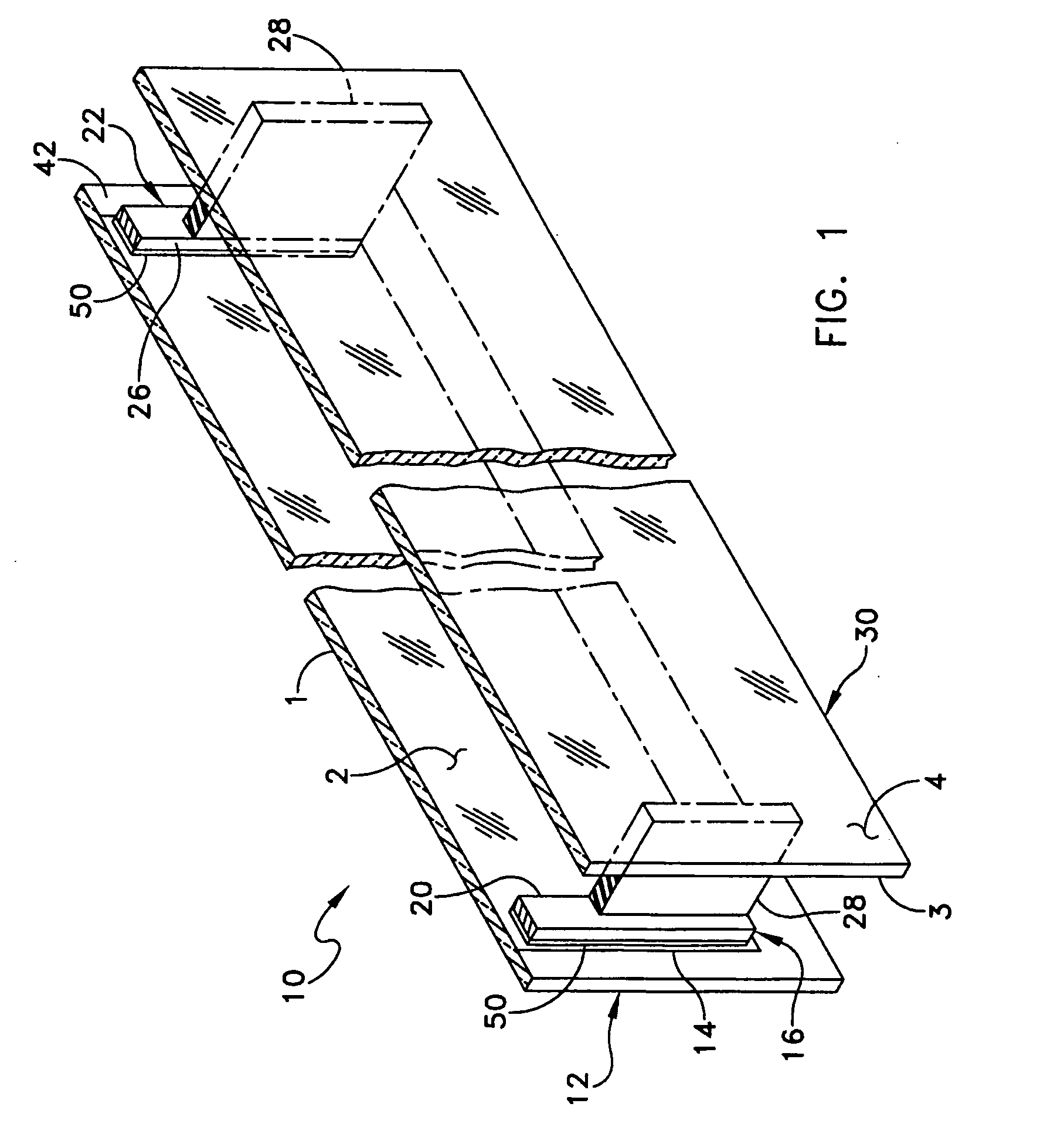

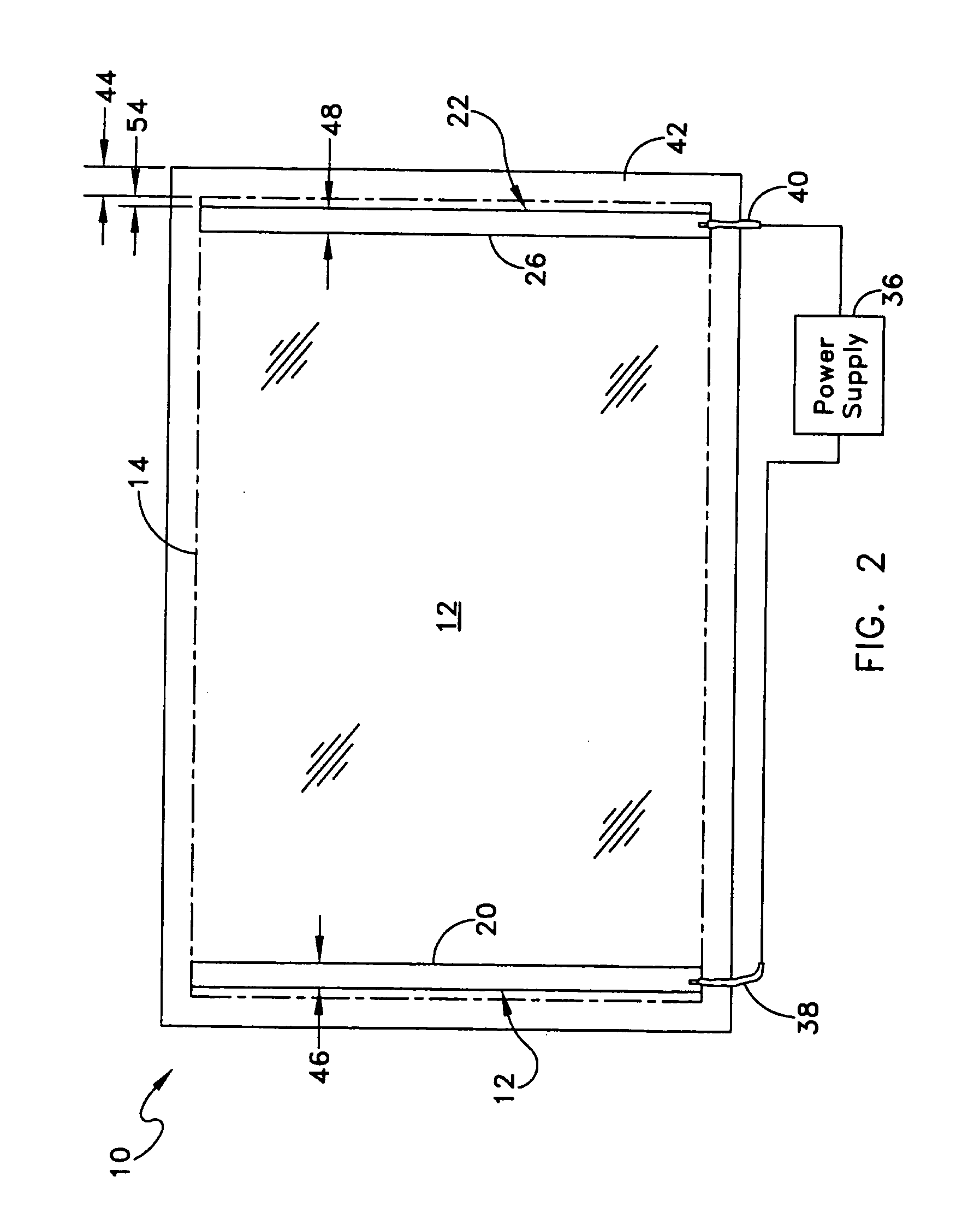

[0021] One embodiment of a heated glass panel 10 according to the teachings provided herein is best seen in FIGS. 1-3 and may comprise a first glass sheet 12 having an electro-conductive film 14 provided thereon. A first conductor 16 or bus bar is positioned at a first location 20 on the electro-conductive film 14. A second conductor 22 is positioned at a second location 26 on the electro-conductive film 14, as best seen in FIG. 2. A resilient material 28 is positioned on the first and second conductors 16 and 22. A second glass sheet 30 is positioned on the resilient material 28 in the manner best seen in FIG. 3, so that the resilient material 28 and conductors 16, 22 are sandwiched between the first and second glass sheets 12 and 30. The first and second glass sheets 12 and 30 are held together so that they exert a compressive pressure (illustrated by arrows 32) on the resilient material 28 and the first and second conductors 16 and 22, thereby holding the first and second conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com