Method for using anionic zinc houghite for preparing zinc cathode of zinc-nickel secondary battery

An application method, an anion-type technology, applied in battery electrodes, alkaline battery electrodes, circuits, etc., can solve the problem of reducing the capacity of zinc oxide, and achieve the effects of improving electrochemical performance, long cycle life and good reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

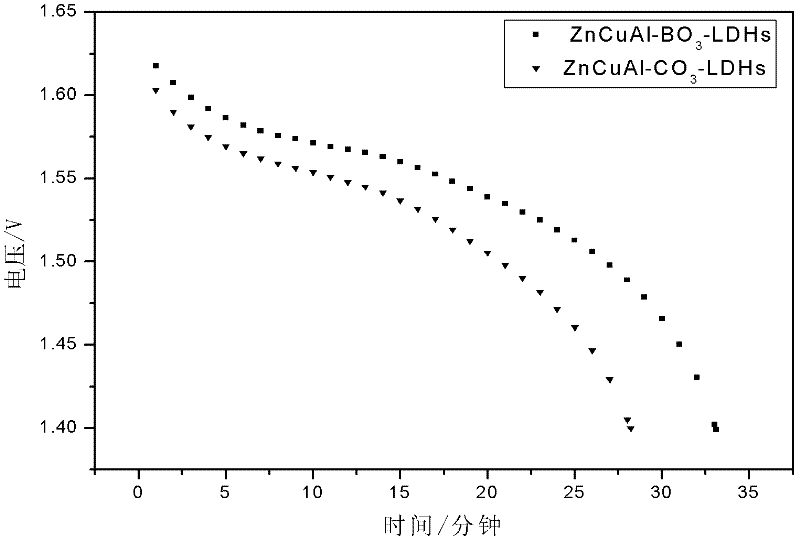

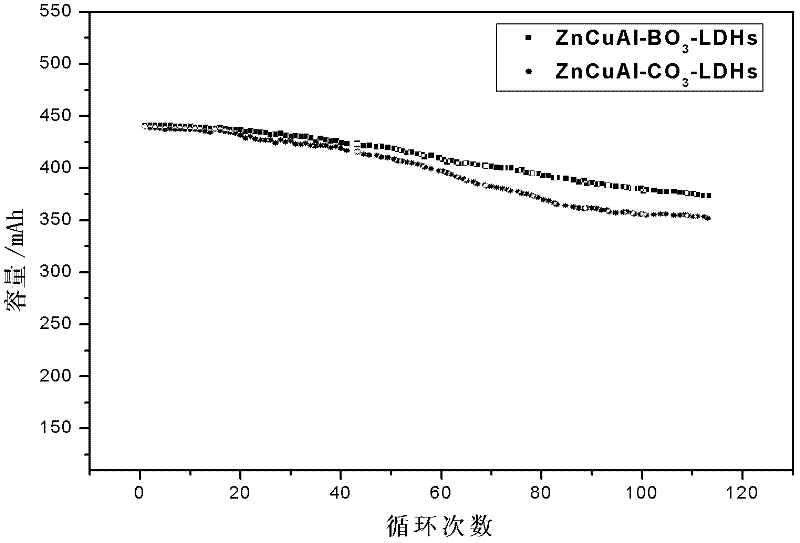

Embodiment 1

[0029] The analytical pure zinc nitrate of 7.72 weight parts and the analytical pure copper nitrate of 1.26 weight parts are dissolved in the deionized water of 100 weight parts, the analytical pure aluminum nitrate of 3.75 weight parts is dissolved in the deionized water of 100 weight parts, will The above two solutions are mixed uniformly to form a salt solution. 3.2 parts by weight of sodium hydroxide and 2.12 parts by weight of sodium carbonate were dissolved in 50 parts by weight of deionized water to form an alkaline solution. Under strong mechanical stirring, slowly add the salt solution and alkali solution dropwise into 50 parts by weight of deionized water, control the pH of the solution to 10.0, continue to stir for 80 minutes, age for 20 hours, and finally filter and wash the precipitate. Dry at 60°C for 4 hours to obtain carbonate-type zinc-copper-aluminum hydrotalcite (m 2+ / M 3+= 3:1) samples. 4.9 parts by weight of the sample was prepared into a hydrotalcite ...

Embodiment 2

[0031] The analytical pure zinc nitrate of 10.69 weight parts and the analytical pure copper nitrate of 1.26 weight parts are dissolved in the deionized water of 100 weight parts, the analytical pure aluminum nitrate of 3.75 weight parts is dissolved in the deionized water of 100 weight parts, Mix the above two solutions evenly to form a salt solution. 5.60 parts by weight of potassium hydroxide and 2.76 parts by weight of potassium carbonate were dissolved in 50 parts by weight of deionized water to form an alkaline solution. Under strong mechanical stirring, slowly add the salt solution and the alkali solution dropwise into 50 parts by weight of deionized water, control the pH of the solution to 10.0, continue to stir for 100 minutes, age for 20 hours, and finally filter and wash the precipitate. Dry at 60°C for 4 hours to obtain carbonate-type zinc-copper-aluminum hydrotalcite (M 2+ / M 3+ = 4:1) samples. 4.9 parts by weight of the sample was prepared into a hydrotalcite ...

Embodiment 3

[0033] The analytical pure zinc nitrate of 13.66 weight parts and the analytical pure copper nitrate of 1.26 weight parts are dissolved in the deionized water of 100 weight parts, the analytical pure aluminum nitrate of 3.75 weight parts is dissolved in the deionized water of 100 weight parts, Mix the above two solutions evenly to form a salt solution. 6.72 parts by weight of potassium hydroxide and 2.76 parts by weight of potassium carbonate were dissolved in 50 parts by weight of deionized water to form an alkaline solution. Under strong mechanical stirring, slowly add the alkaline solution and the alkaline solution dropwise into 50 parts by weight of deionized water, control the pH of the solution to 10.0, continue to stir for 120 minutes, age for 20 hours, and finally filter and wash the precipitate. Dry at 60°C for 4 hours to obtain carbonate-type zinc-copper-aluminum hydrotalcite (M 2+ / M 3+ =5:1) samples. 4.9 parts by weight of the sample was prepared into a hydrotal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com