Ventilated housing and assembly

a technology of ventilated housing and housing housing, which is applied in the direction of combustion treatment, modification using gaseous coolants, light and heating apparatus, etc., can solve the problems of loss of potential revenue, the inability of cable management systems to meet the requirements of industry standards for both front and rear dressing of cables, and the overheating of the upper unit, etc., to achieve the effect of saving vertical space, reducing requirements, and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

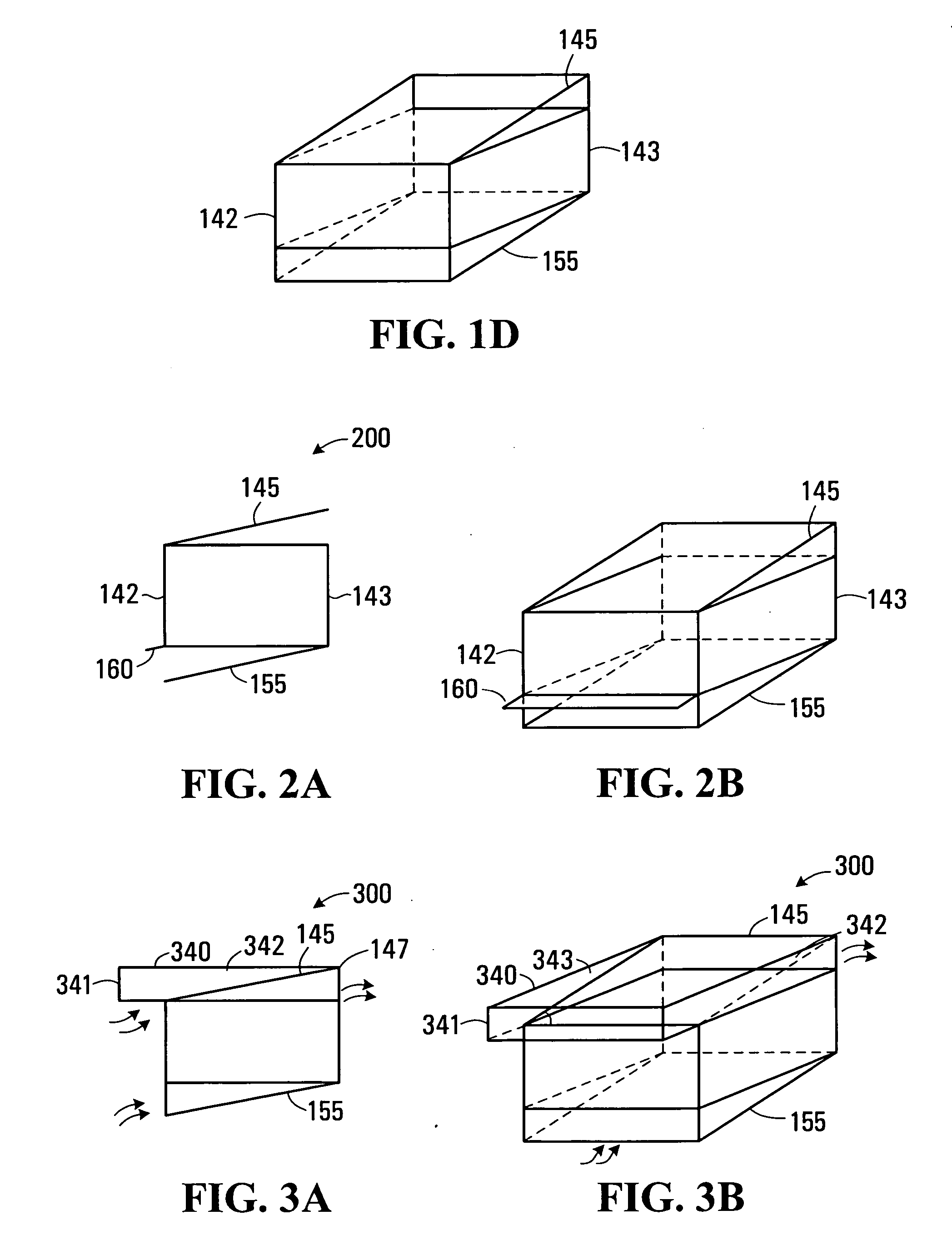

[0030] For ease of reference, the same reference numerals are used to refer to parts that perform the same function in each embodiment.

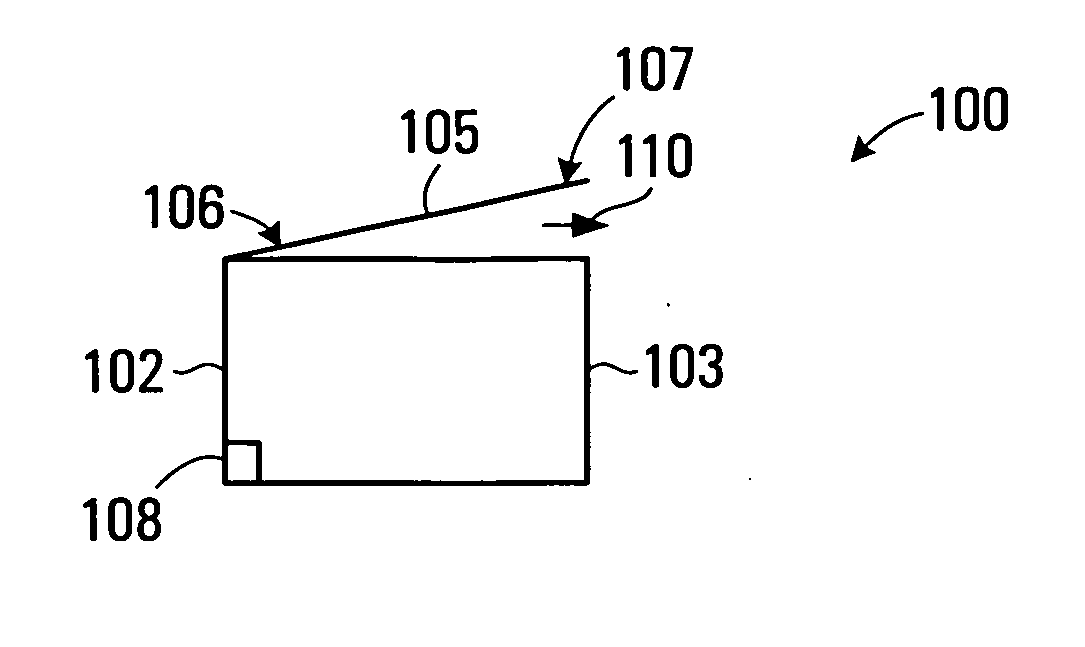

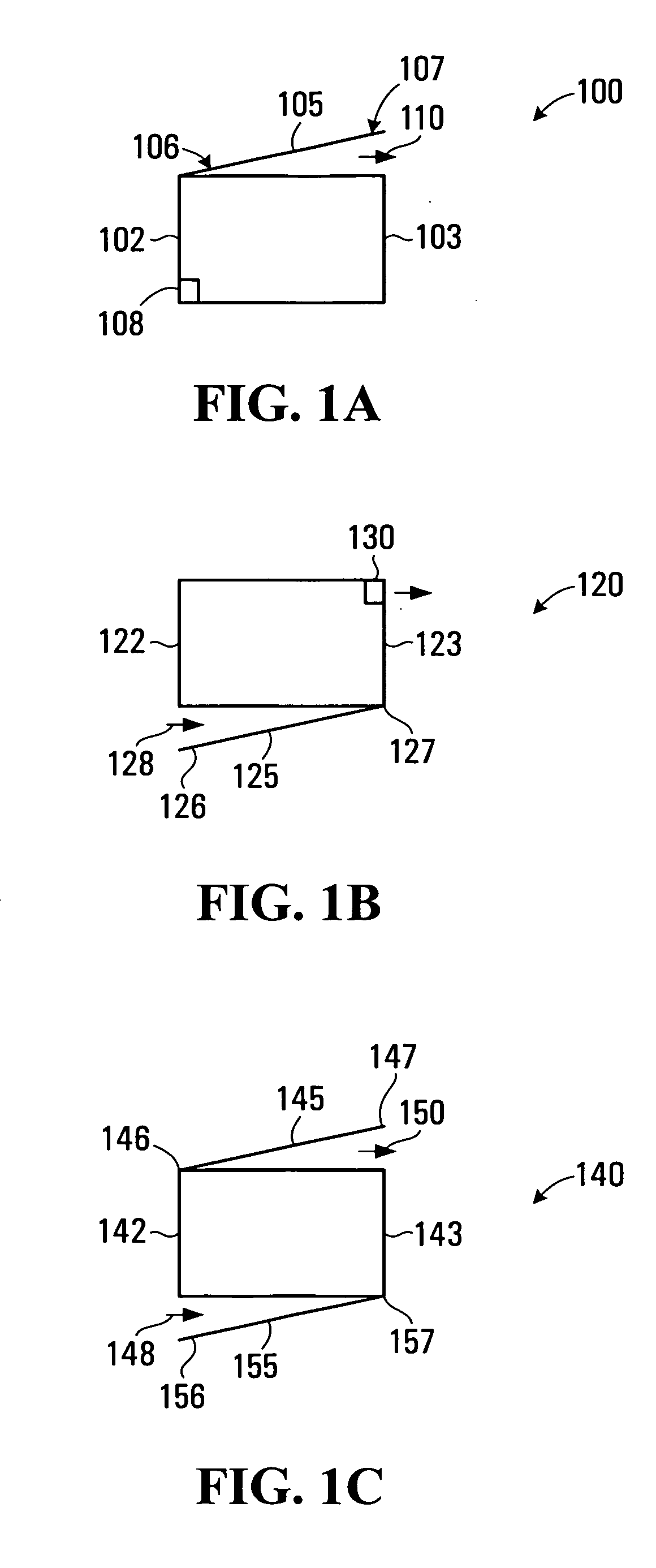

[0031] Referring to FIG. 1A, one embodiment of a ventilated housing 100 for accommodating one or more component comprises opposed first and second spaced-apart end portions 102 and 103. An upper air barrier 105 extends at least partially between the first and second end portions 102 and 103 and has an upper surface. In some embodiments, the upper air barrier 105 defines an upper surface of the ventilated housing 100. In other embodiments, the housing also comprises a louver structure or a perforated support (not shown) above the upper air barrier 105. The upper air barrier 105 limits upward movement of air inside the housing 100. A first part 106 of the upper air barrier 105 proximate the first end portion 102 is positioned at a level below the level of a second part 107 of the upper air barrier 105 proximate the second end portion 103. An inlet 108...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com