Ground freezing method and apparatus with geothermal gradient compensation

a geothermal gradient and ground freezing technology, applied in the field of artificial ground freezing, can solve the problems of uneven subterranean frozen barrier formation, lack of uniform ground freezing from top to bottom, long time, etc., and achieve the effect of improving functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

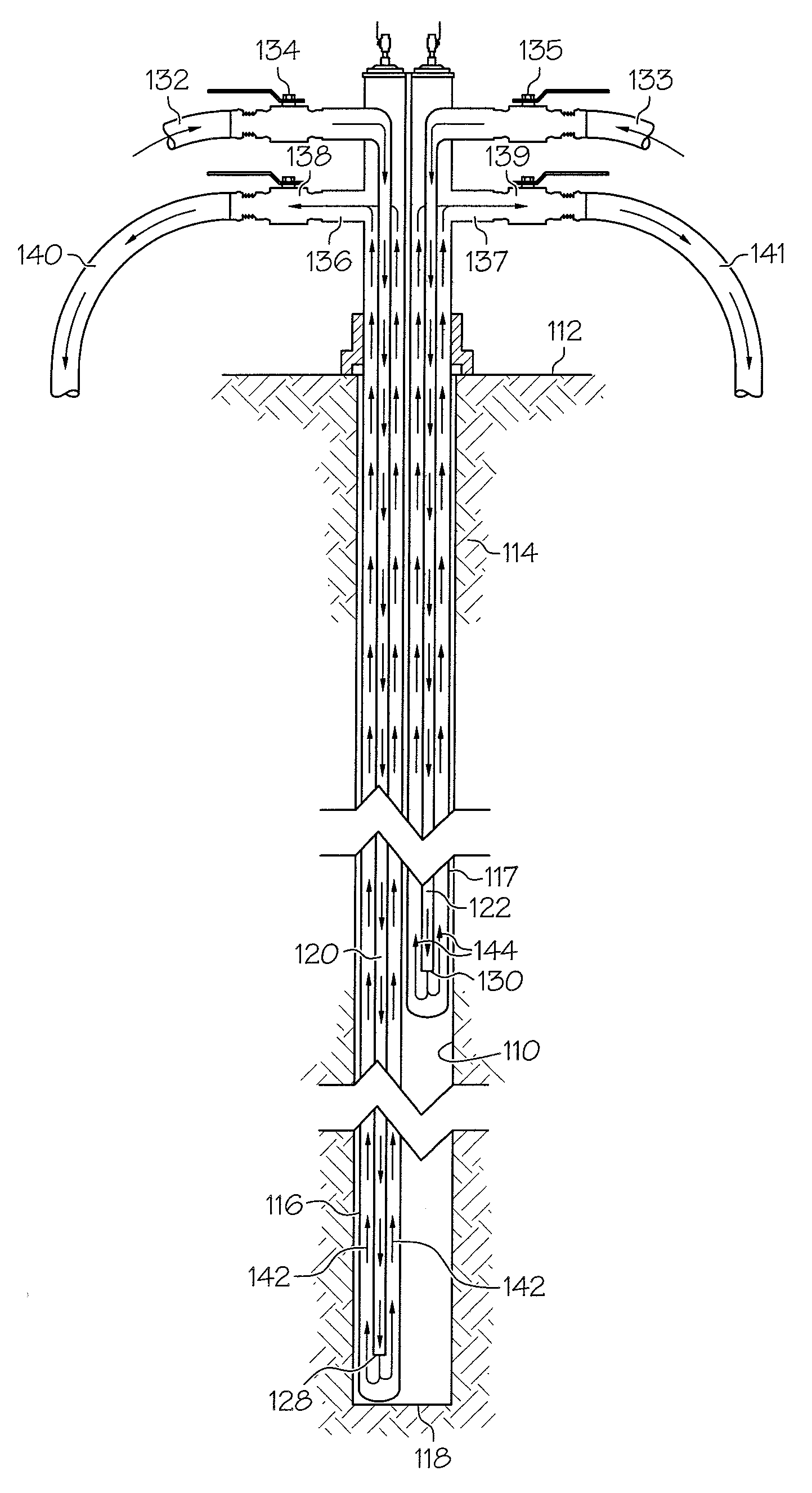

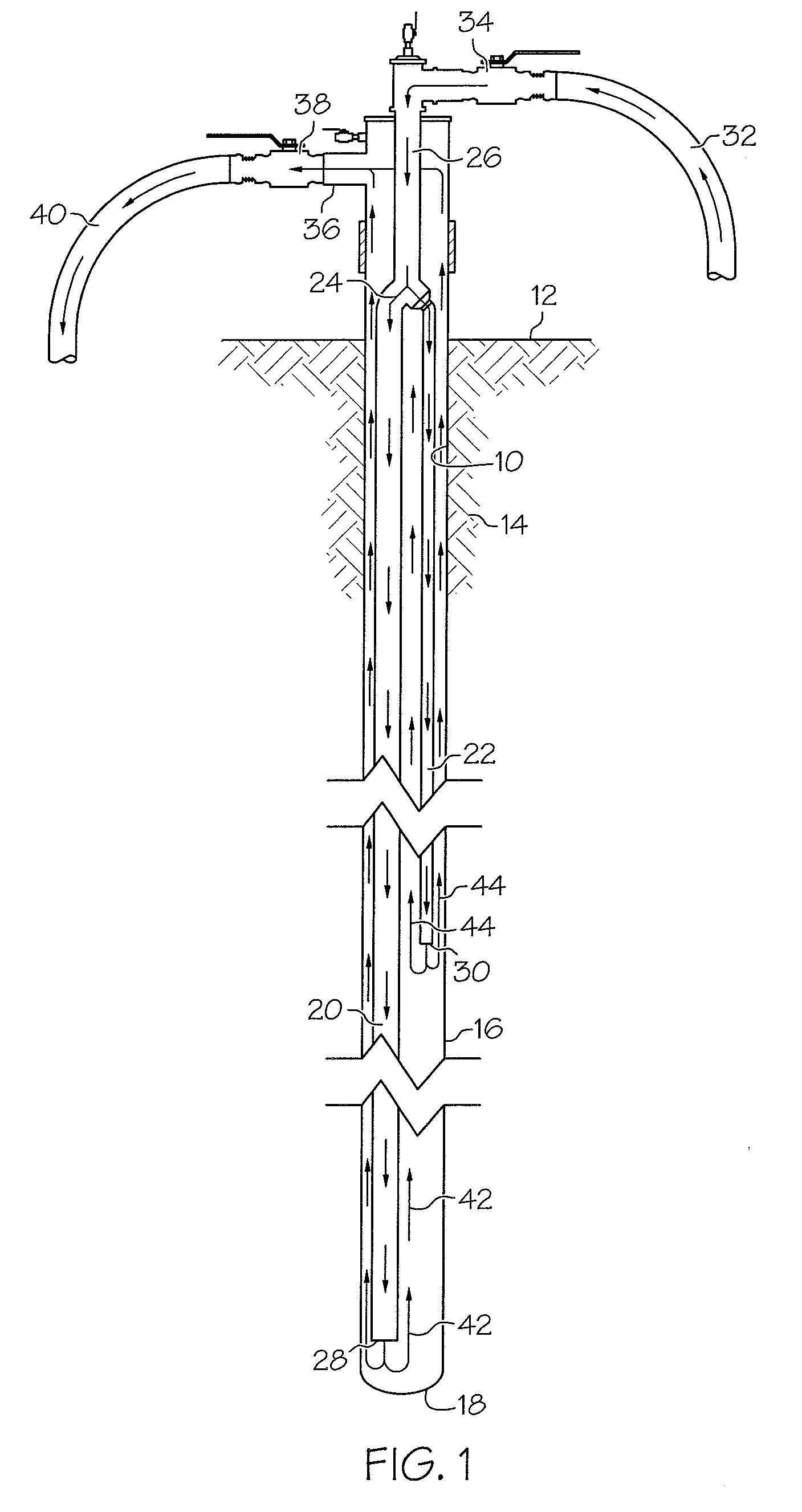

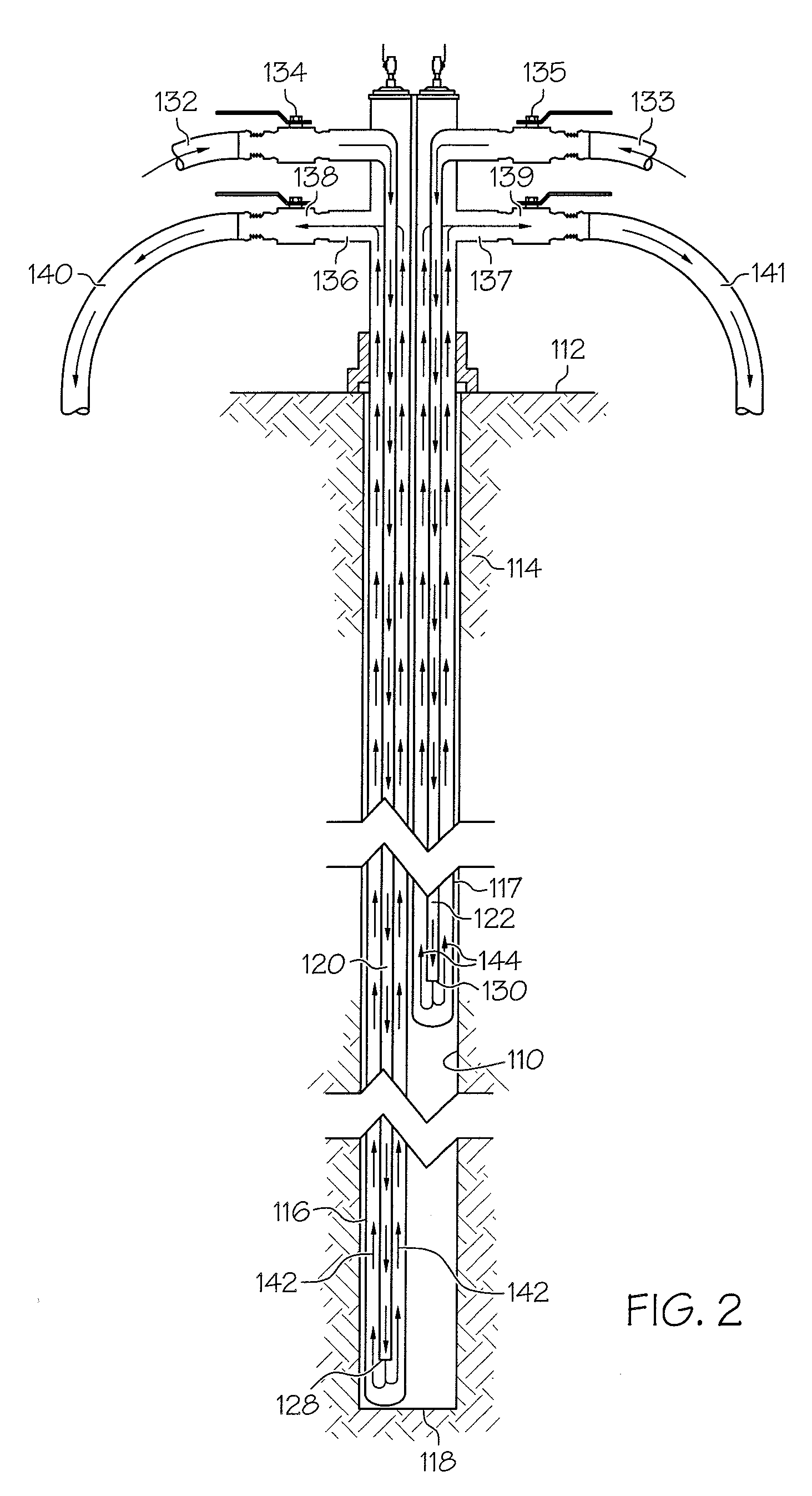

[0013]Referring now to the drawings in more detail and initially to FIG. 1, the present invention is directed to a method and apparatus for ground freezing which involves drilling of a bore 10 downwardly from the surface 12 into the ground or earth 14. A freeze pipe 16 which may be constructed of steel or another metal is installed in the bore 10 generally in contact with the sidewall of the bore. The freeze pipe 16 may extend to the bottom or base 18 of the bore 10.

[0014]Extending side by side within the freeze pipe 16 are a pair of feed pipes 20 and 22. At their upper ends, pipes 20 and 22 are connected by a Y fitting 24 with a common supply pipe 26. Pipe 20 is substantially longer than pipe 22 and extends downwardly from the Y fitting 24 to an open lower end 28 which is spaced slightly above the bottom of the freeze pipe 16 near the base 18 of the bore. Pipe 22 has an open lower end 30 which is located well above end 28 of pipe 20 at a mid-depth location within the freeze pipe 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com