Method and process of non-isothermal aging for aluminum alloys

a non-isothermal aging and aluminum alloy technology, applied in the field of non-isothermal heat treatment of aluminum alloys, can solve the problems of incoherent matrix, low yield strength, long aging time, etc., and achieve the effects of increasing costs, long aging times, and high amounts of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

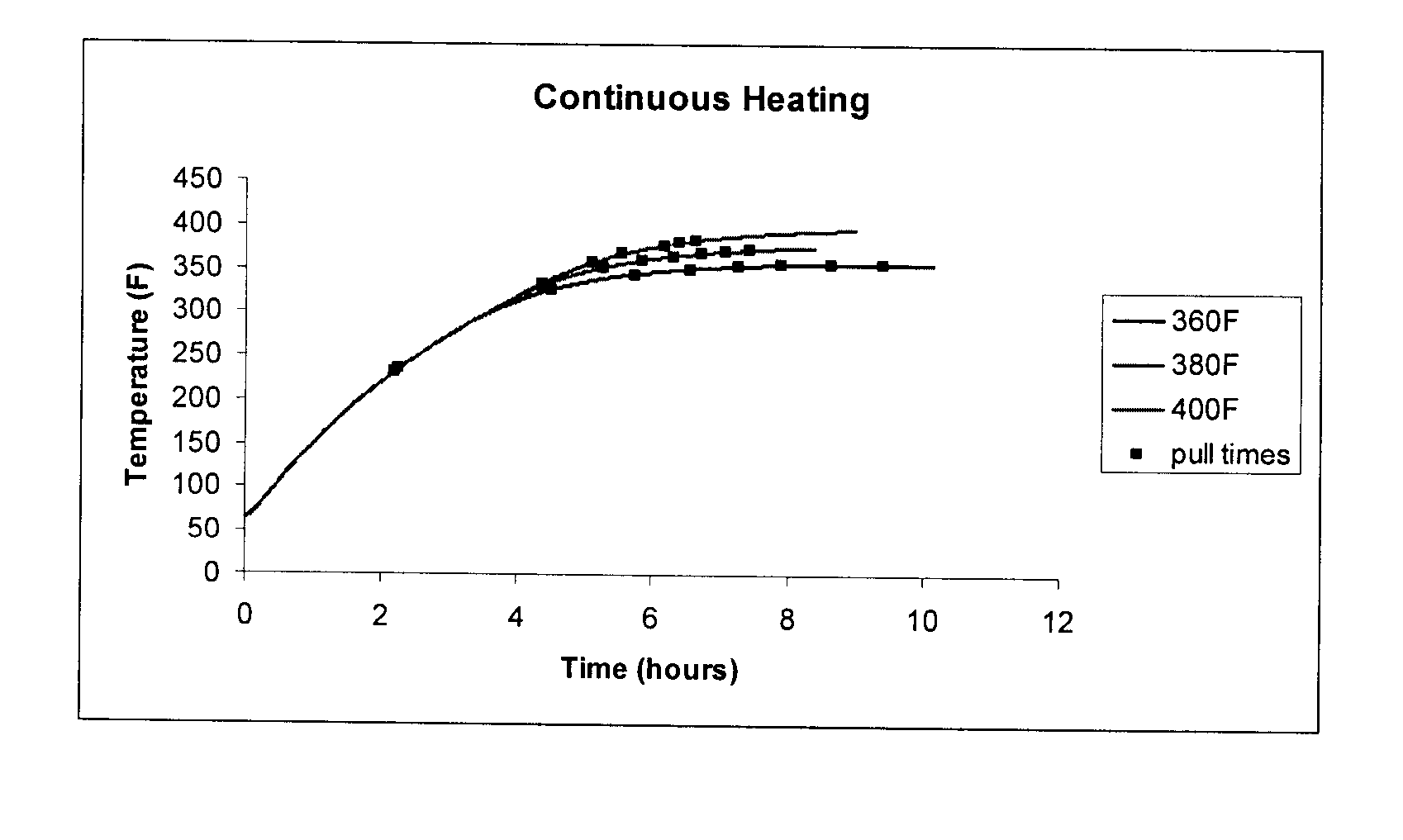

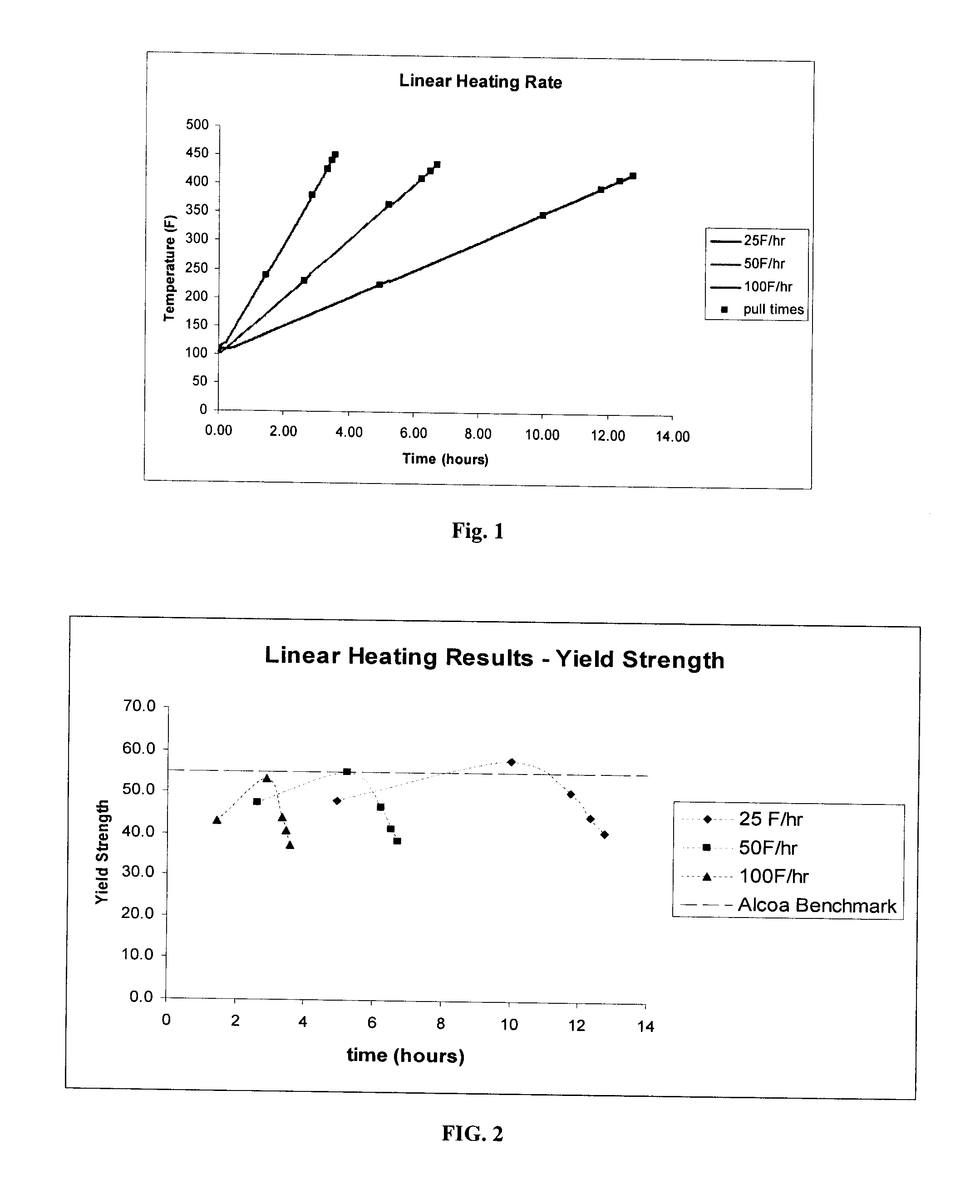

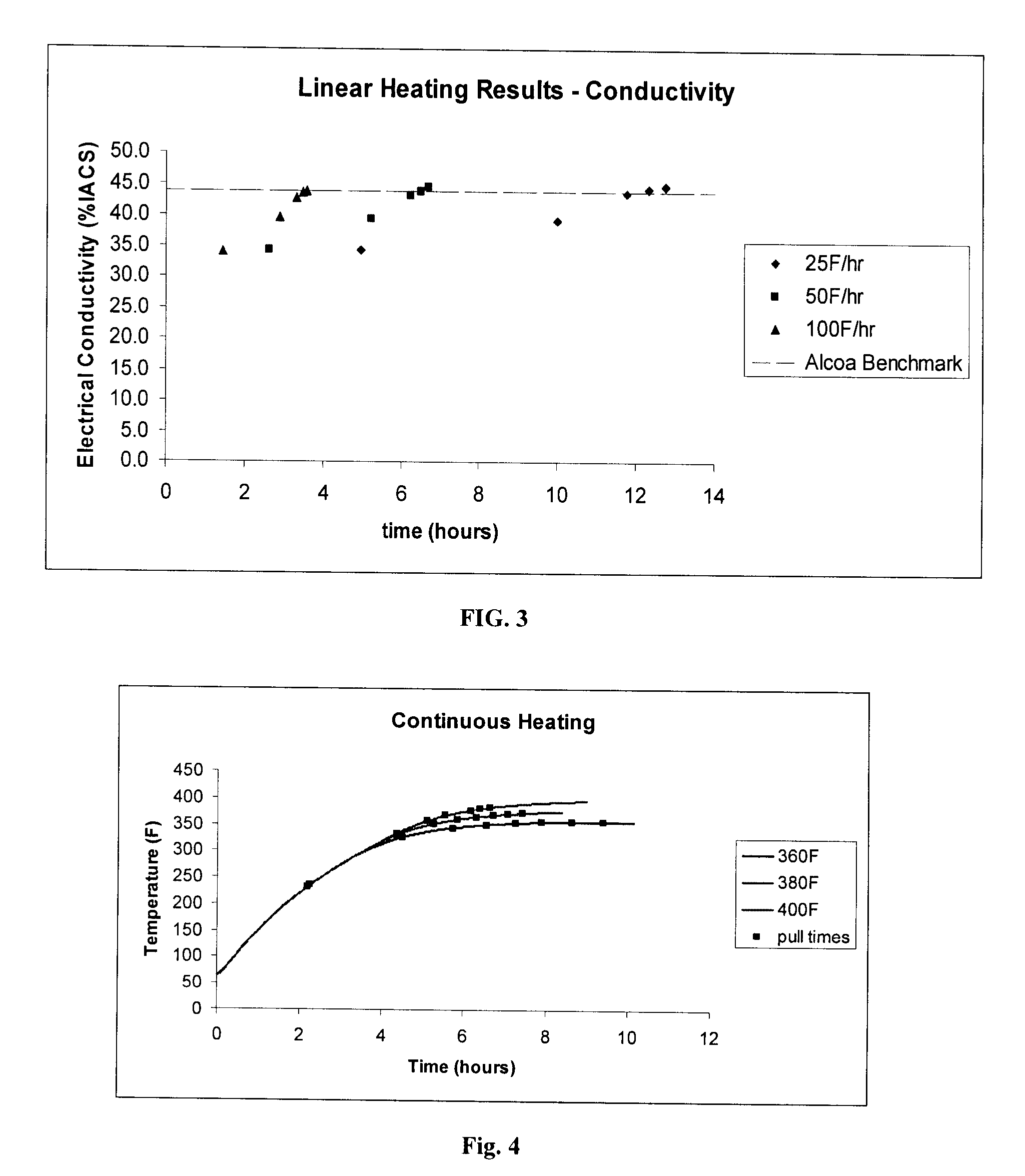

[0022] In accordance with the present disclosure, an aluminum base alloy is aged in a non-isothermal process with continuous heating. By providing a continuously increasing heat rate, the separate aging stages at different temperatures can be replaced. In exemplary embodiments, the heating rate is increase linearly.

[0023] In addition to aluminum alloys, other precipitation hardenable alloys can also be aged in a non-isothermal process. For example, copper and nickel alloys are precipitation hardenable alloys that could be aged using the disclosed non-isothermal aging process.

[0024] In particular embodiments, the non-isothermal aging method is used with 7000 series aluminum alloys. The 7000 series alloy comprises aluminum, about 1.5 to 14 wt. % zinc, 0.8 to 3.8 wt. % magnesium, 0.25 to 2.6 wt. % copper and at least one additional alloying element selected from the group consisting of 0.05 to 0.4 wt. % chromium, 0.1 to 0.75 wt. % manganese, 0.05 to 0.3 wt. % zirconium, 0.05 to 0.3 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com