Doll Joint

a doll and joint technology, applied in the field of doll joints, can solve the problems of compromising the lifelike effect of the doll, the doll cannot have a lifelike appearance, and the position cannot be maintained without assistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

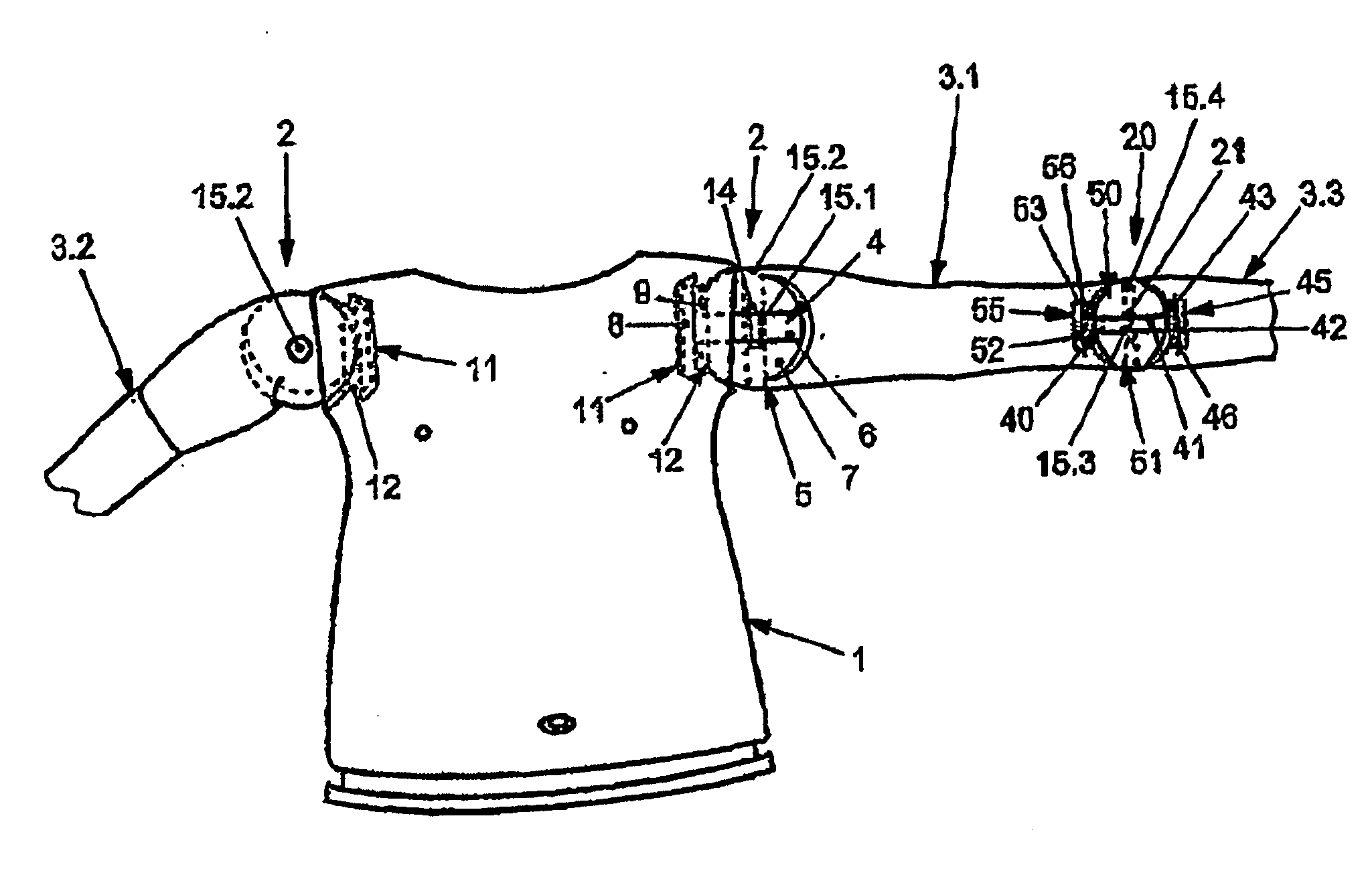

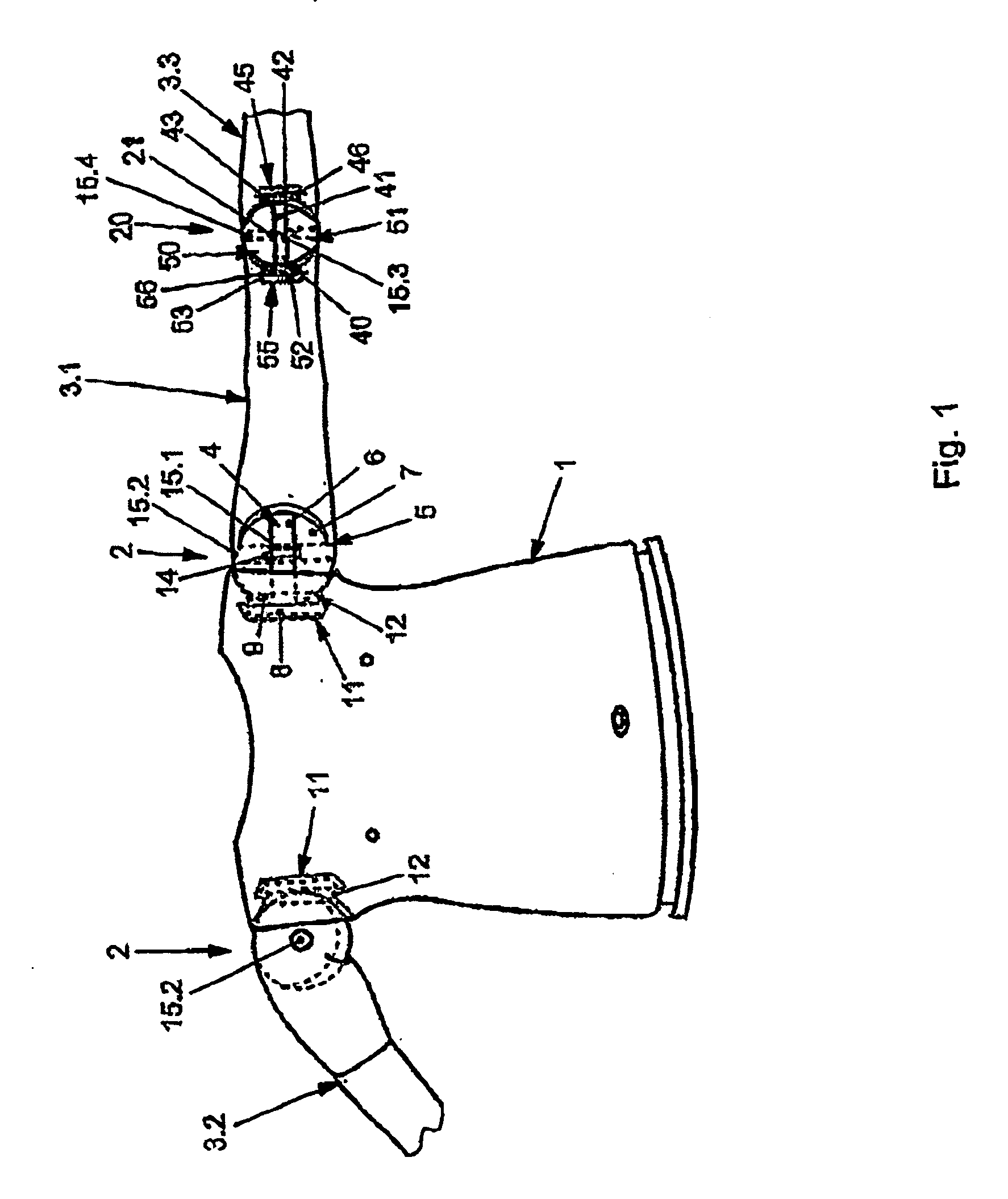

[0035]FIG. 1 depicts the upper region of a doll's body 1 to which a doll's arm part 3.1 or 3.2 is secured via a respective joint 2. At the other end, a further doll's arm part 3.3 is secured on the doll's arm part 3.1 via a further joint 20.

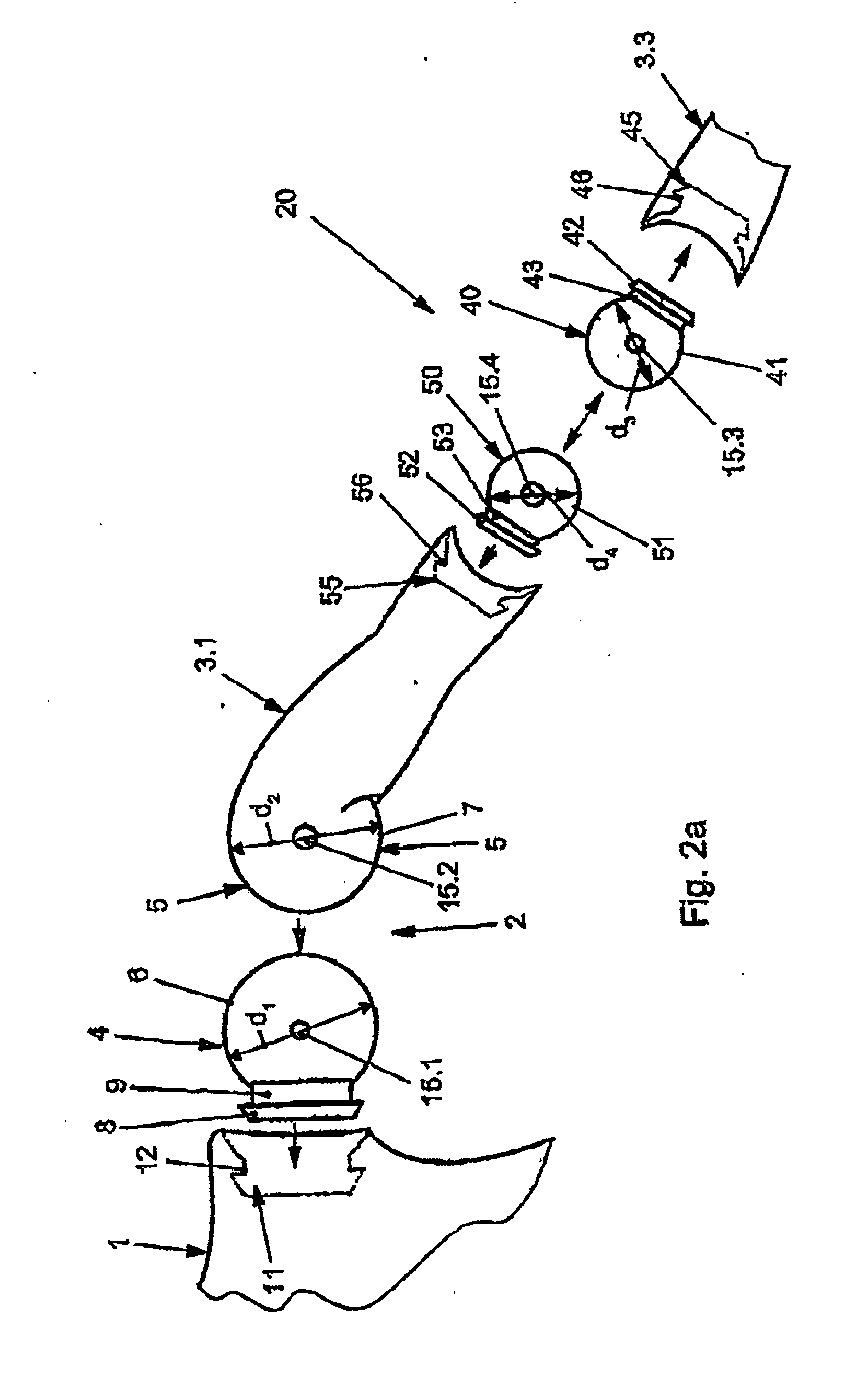

[0036] The joints 2 and 20 are composed, as shown in FIGS. 2a and 2b, of a rotary element 4, 40, preferably in the form of a disk, and of a spherical end area 5 of the doll's arm part 3.1 itself or a spherical element 50. A diameter d1, d3 of the rotary element 4, 40, respectively, corresponds to a diameter d2, d4 of the spherical end area 5 of the doll's arm part 3.1 and the spherical element 50, so that outer faces 6, 7 of the rotary element 4 and of the spherical end area 5 or outer faces 41, 51 of the rotary element 40 or of the spherical end 50 lie almost in one plane in the position of use and rest flush on one another.

[0037] The rotary element 4, 40 is also assigned a holding element 8, 42, respectively, which is assigned a guide 9, 43, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com