System design and cooling method for LP steam turbines using last stage hybrid bucket

a technology of steam turbines and cooling systems, applied in the direction of liquid fuel engines, machines/engines, mechanical equipment, etc., can solve the problems of reducing reliability, blades contributing to higher disk stresses, and low performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

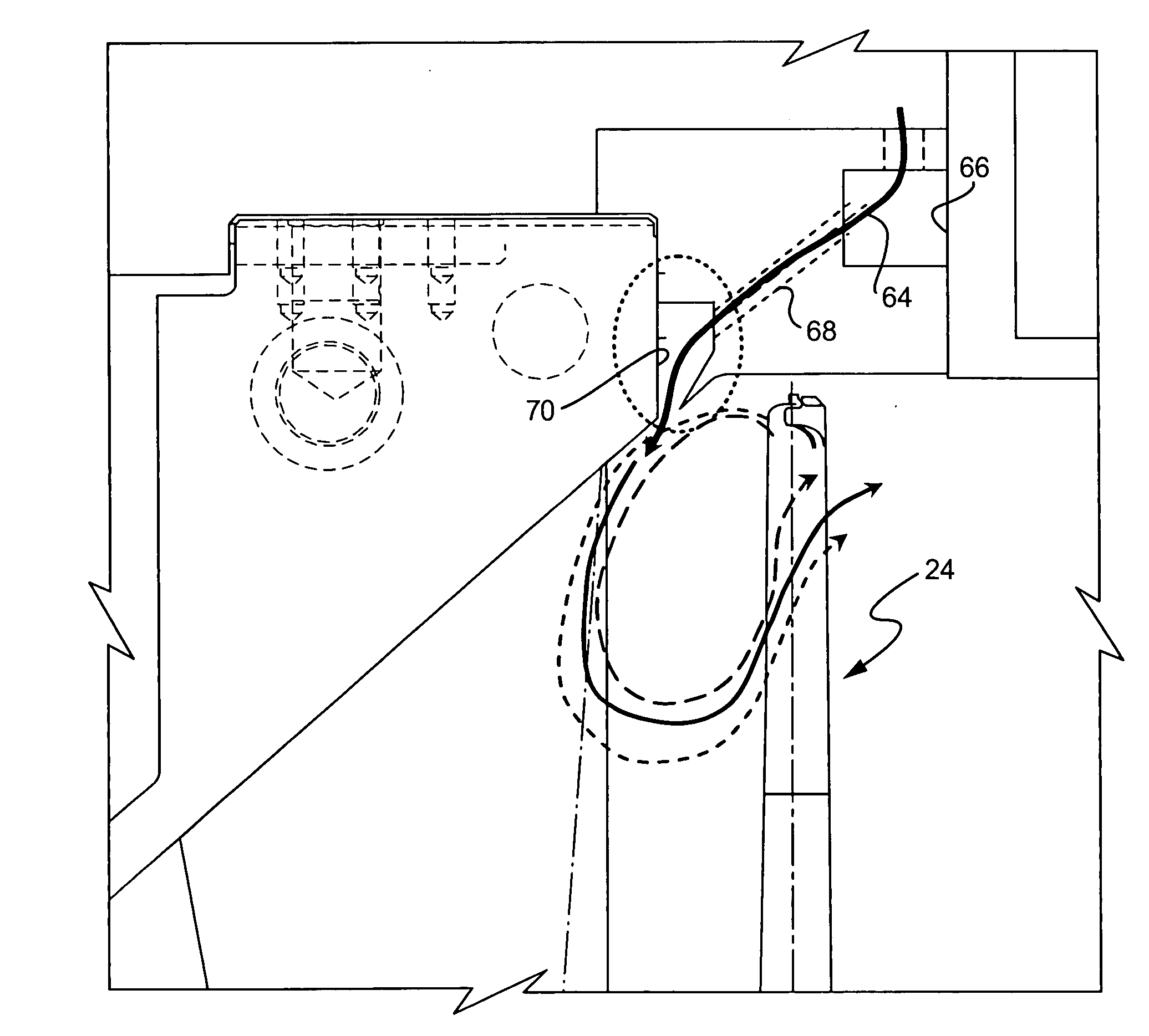

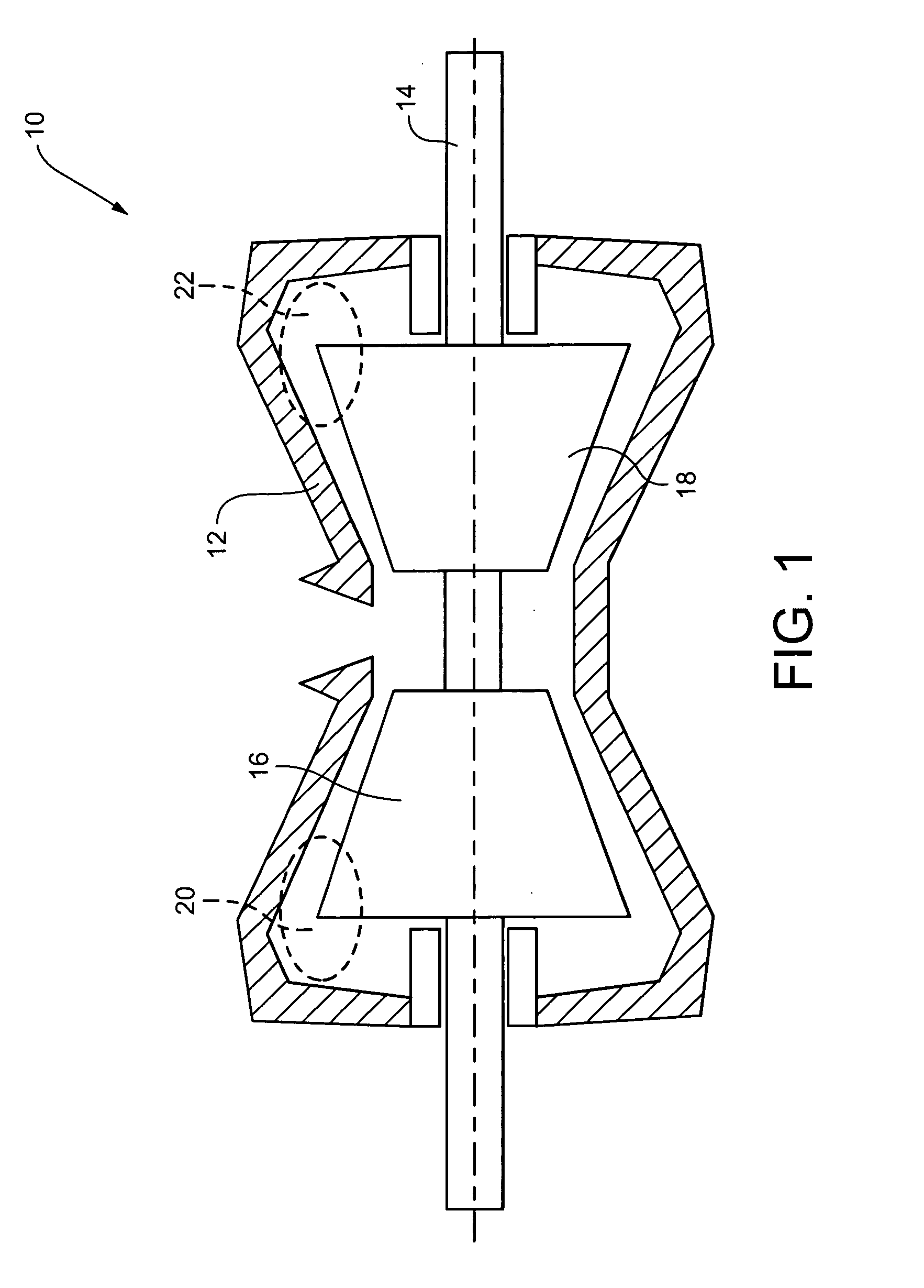

[0017]FIG. 1 is a schematic diagram of a double-flow, low pressure turbine 10 including a turbine casing 12, rotor 14 and a plurality of wheels in two turbine sections indicated at 16, 18. The areas 20, 22 circled in dotted lines represent the radially outermost regions of the last stage blades that have been shown to experience the most windage heating during partial load conditions. Thus, in example embodiments of the invention, steam or water injection, steam extraction, and / or water sprays are used to cool the nozzles and / or buckets of the last stage(s), so that the advantages of hybrid blades for such stage(s) can be realized.

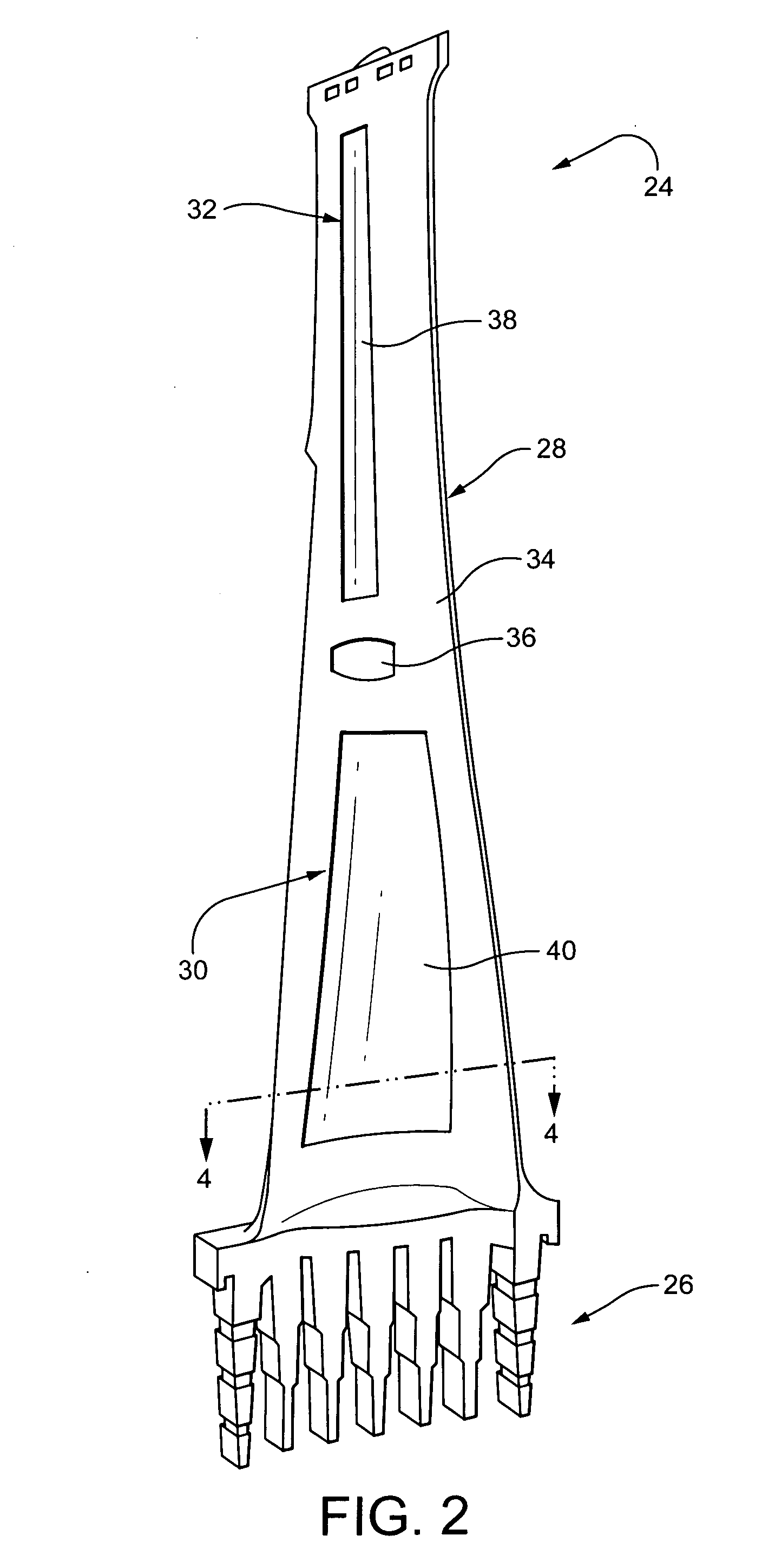

[0018]FIG. 2 schematically shows an example construction of a hybrid steam turbine blade 24. The steam turbine blade includes a shank portion 26 and an airfoil portion 28. The airfoil portion has an operating temperature range, a design rotational speed, a blade root attached to the shank portion, a blade tip, and a radial axis extending outward toward the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com