Side mounted truck tie-down rail

a truck and side mount technology, applied in the direction of packaging, flexible elements, cargo supporting/securing components, etc., can solve the problems of not allowing for the load to be secured and properly synched, inhibiting the use of bed covers, truck caps or tonneau covers, and not providing defined attachment locations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

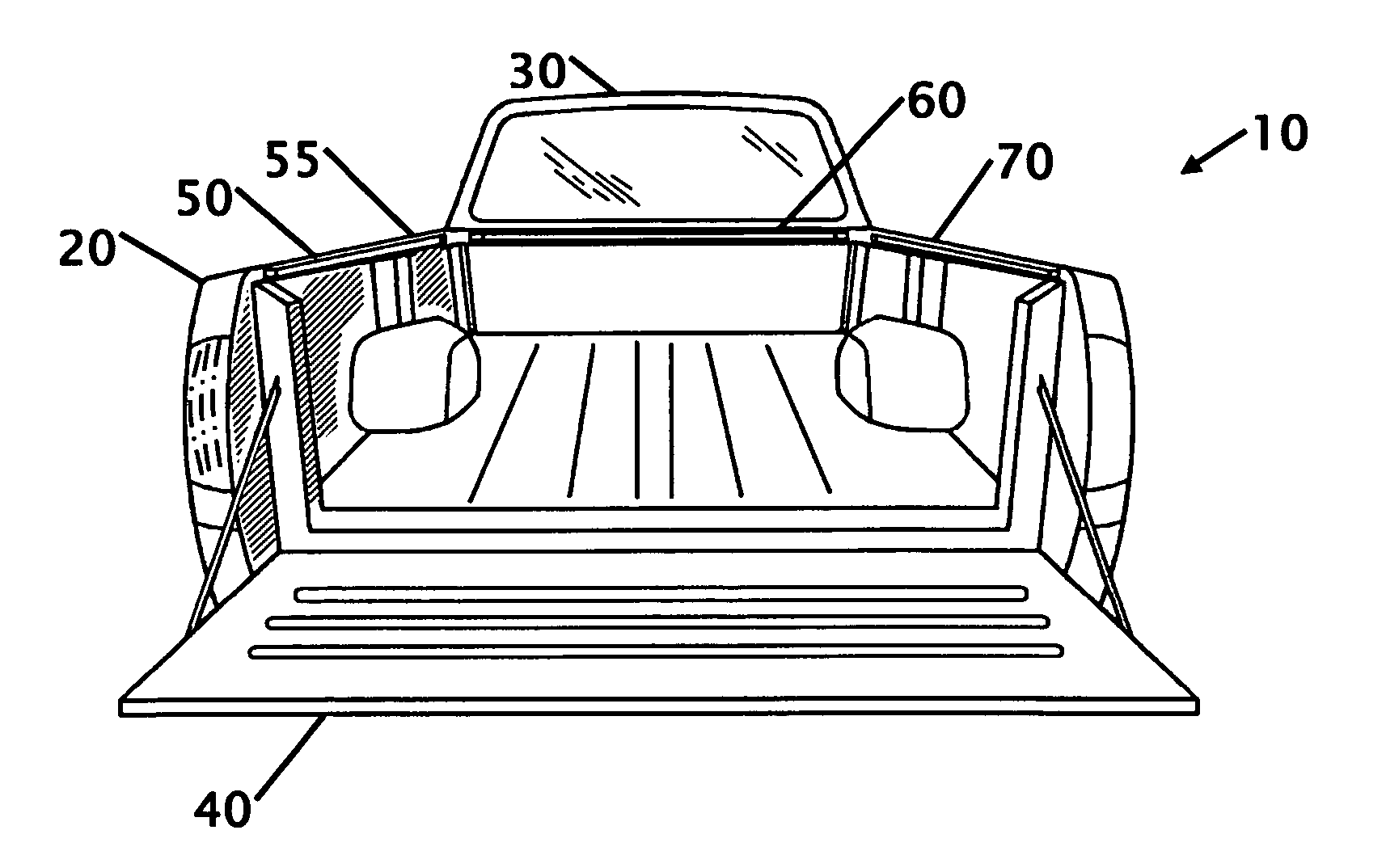

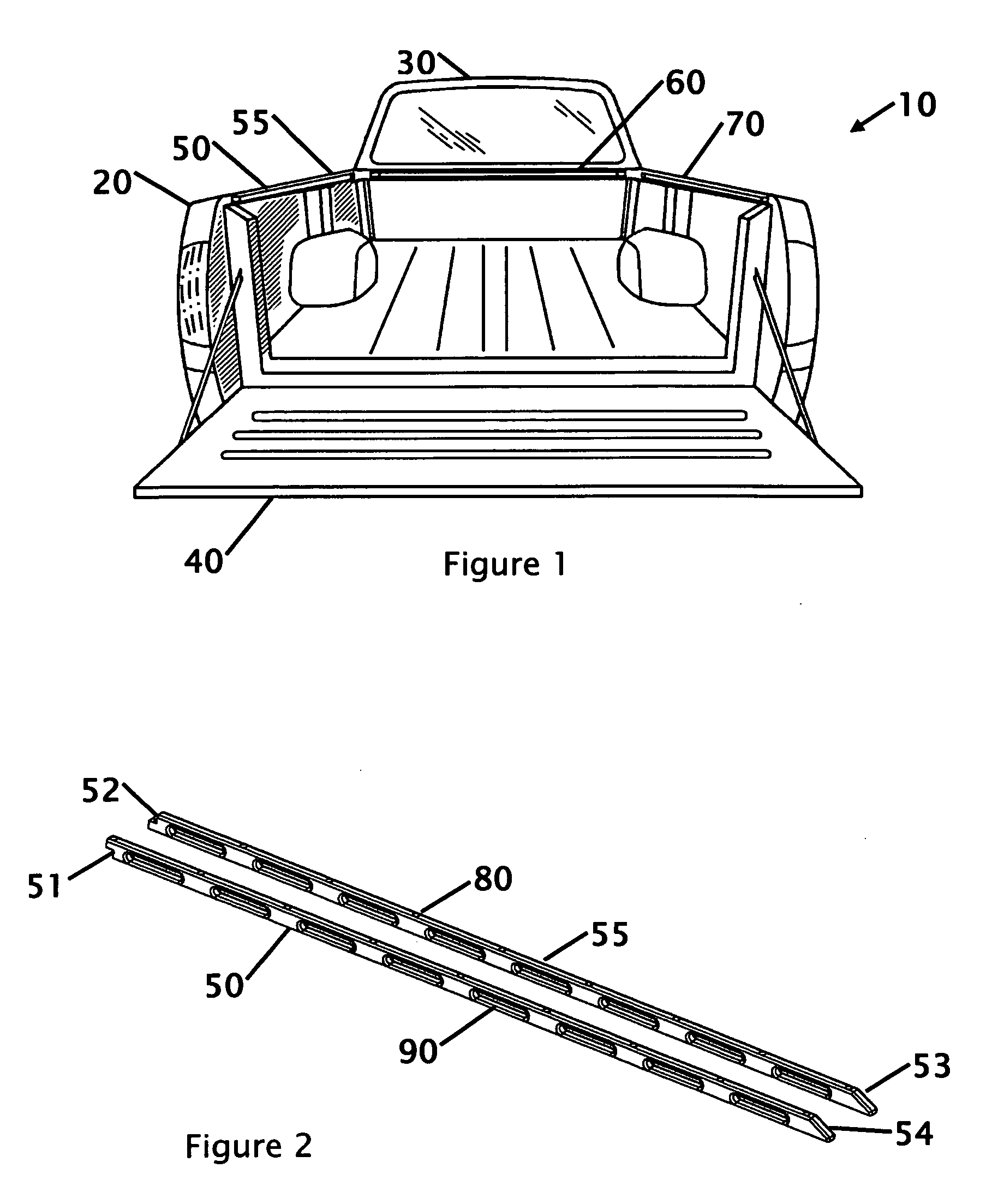

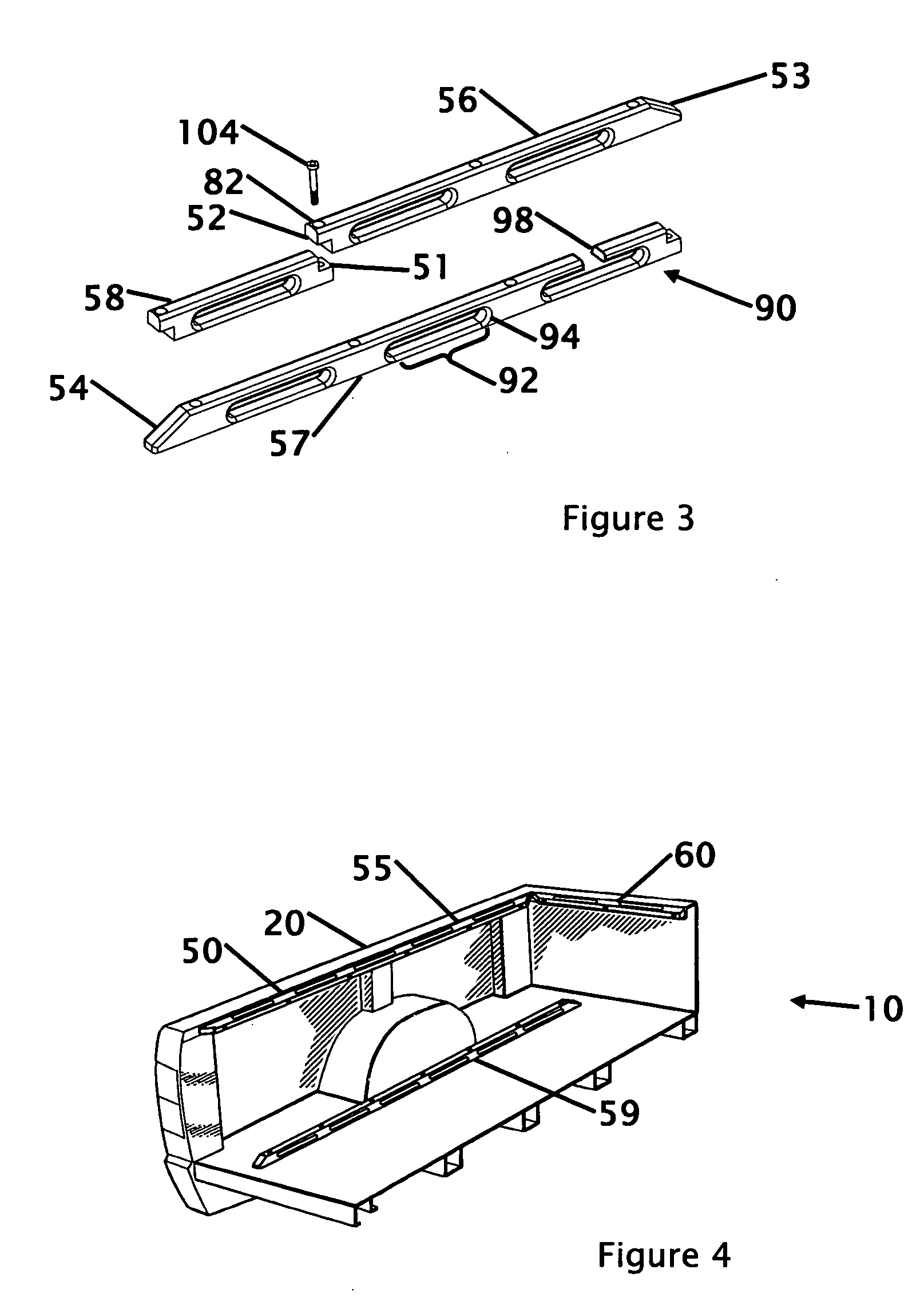

[0023]FIG. 1 shows a view of the side mounted truck tie-downs mounted to the inside of a truck bed. The truck 10 is a typical truck having a front cab section 30 where the driver and any occupants sit. The vehicle has a tailgate 40 that is raised or lowered to allow for placement of items or elongated items. Typically the tailgate is opened an items that will be placed and secured in the back of truck are brought in through the open tailgate. Once the items are brought into the bed of the truck they are secured with tie-downs. In the preferred embodiment the tie downs are located on the inside peripheral edge of the truck bed. In accordance with this embodiment the tie-downs are bolted to the structural flange area formed around the perimeter of the truck bed on the right shown as a single piece 70, left shown in two sections 50 and 55, and the front shown as 60. In securing cargo with most tie-downs that are available today the tie-downs are only available on the right and left sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com