Method and apparatus for loading fibers or cellulose which are contained in a suspension with a filler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

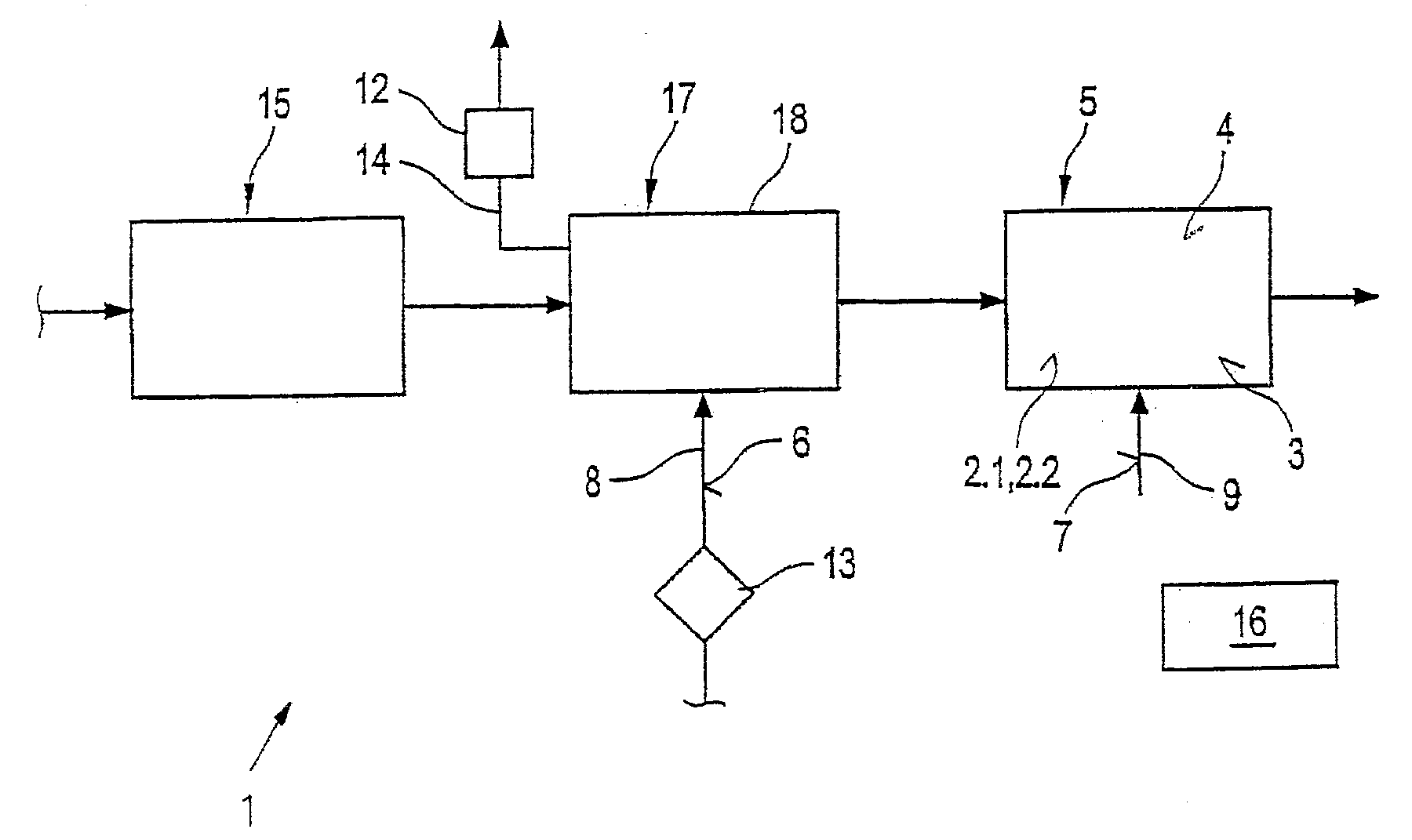

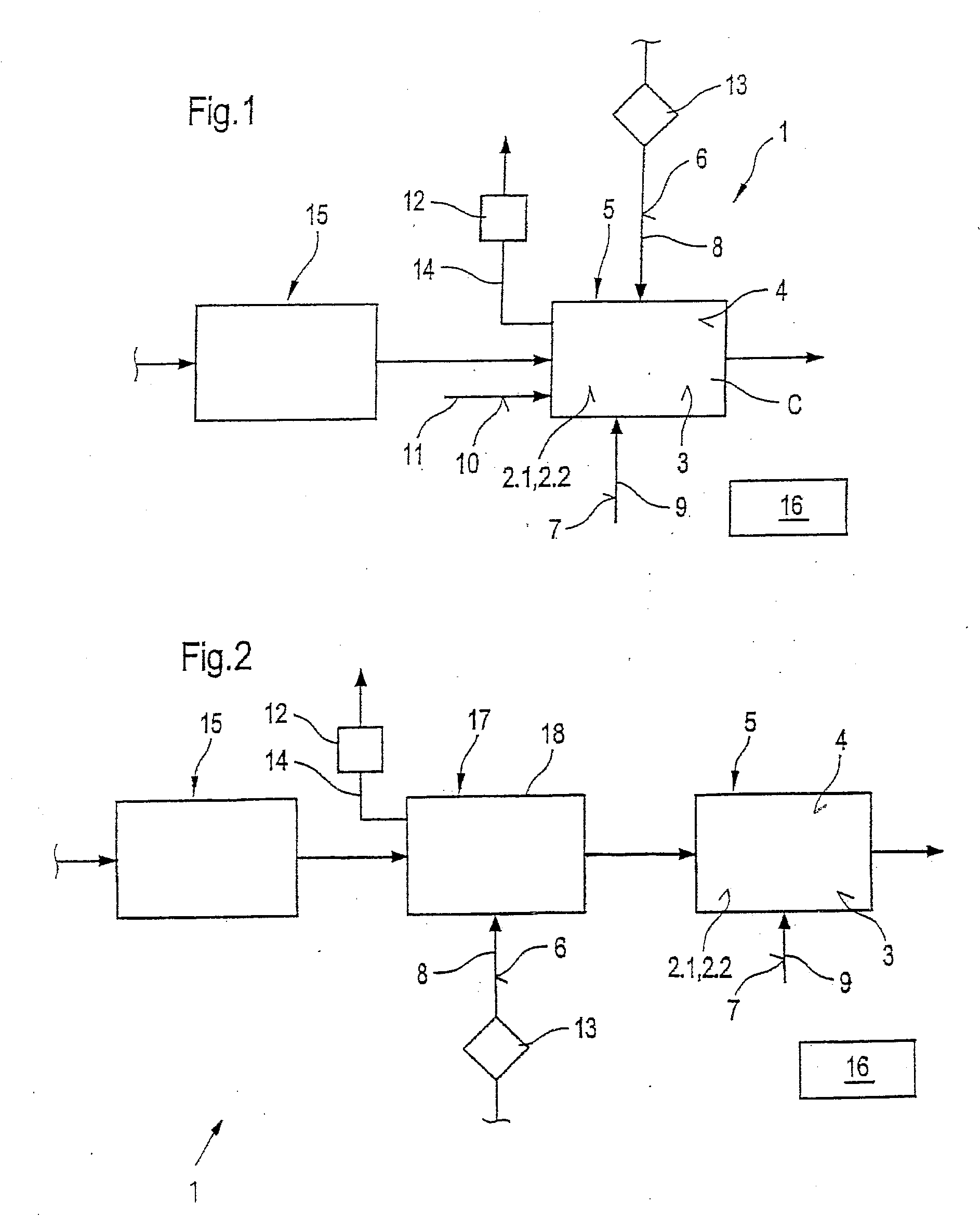

[0040] Referring now to the drawings, and more particularly to FIG. 1, there is shown a schematic depiction of a device 1 for loading fibers 2.1 or cellulose 2.2 which are contained in a suspension 3 with a filler 4 by way of a chemical precipitation reaction, wherein the fibers 2.1 or the cellulose 2.2 in form of a suspension 3 are made available with a pre-determined solids concentration c.

[0041] The apparatus 1 includes reactor 5 in which the fibers 2.1 or the cellulose 2.2 in form of a suspension 3 to which carbon dioxide 6 has been added are mixed with milk of lime or slaked lime 7, thereby triggering and extensively, such as completely, concluding the chemical precipitation reaction. The carbon dioxide 6 can be added to the suspension 3 as pure carbon dioxide and / or as flue gas.

[0042] In the example of apparatus 1 depicted in FIG. 1 the addition of the carbon dioxide 6 and mixing of the milk of lime or slaked lime 7 occurs in batch operation.

[0043] The reactor 5 includes at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com