Bolster spring suspension assembly

a suspension system and bolster spring technology, applied in the direction of springs/dampers, mechanical devices, transportation and packaging, etc., can solve the problems of not being able to easily add, not controlling the jounce or roll of the vehicle chassis in relation, and requiring substantial modification of the entire suspension system, so as to reduce jounce, provide a smooth ride, and reduce the effect of joun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

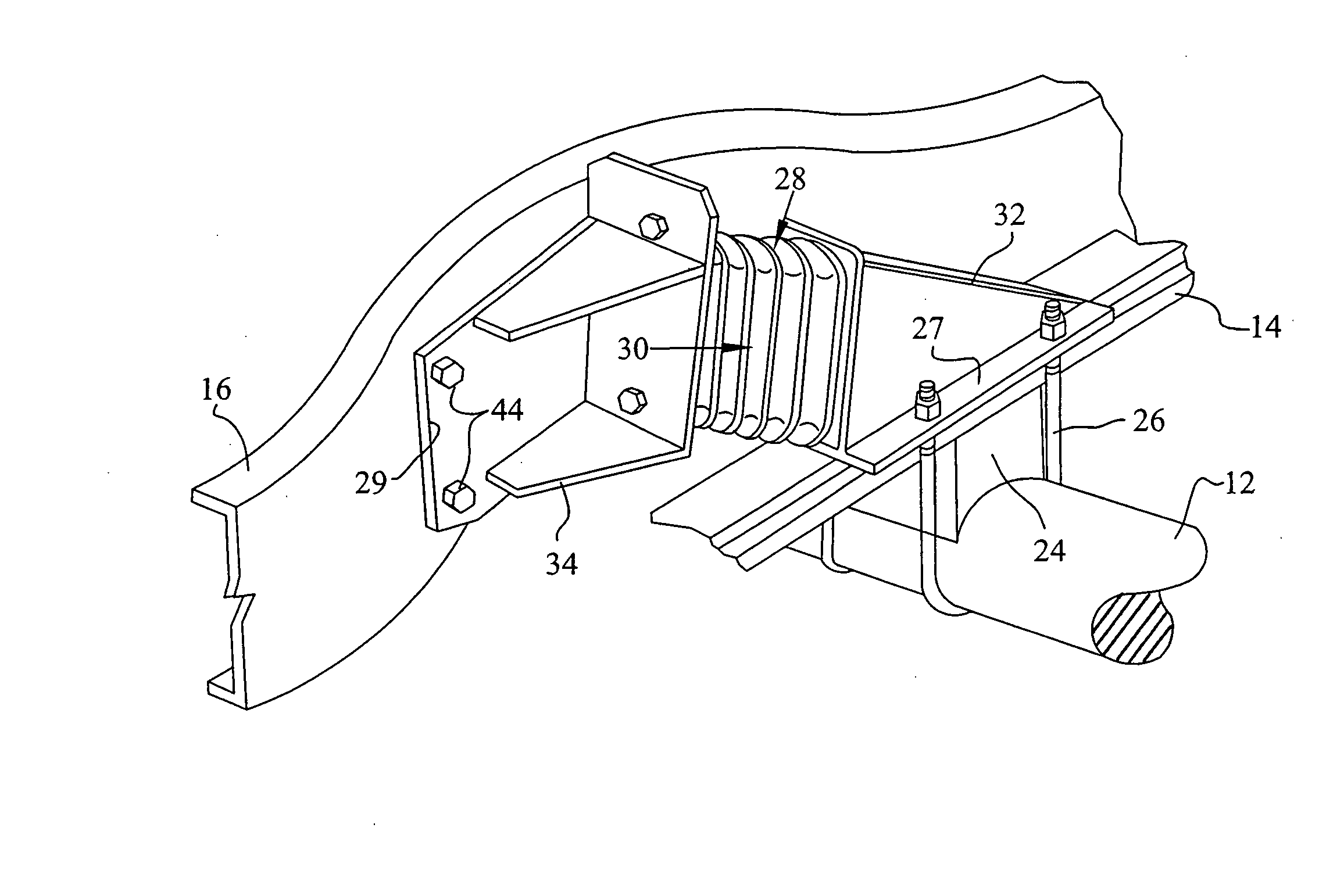

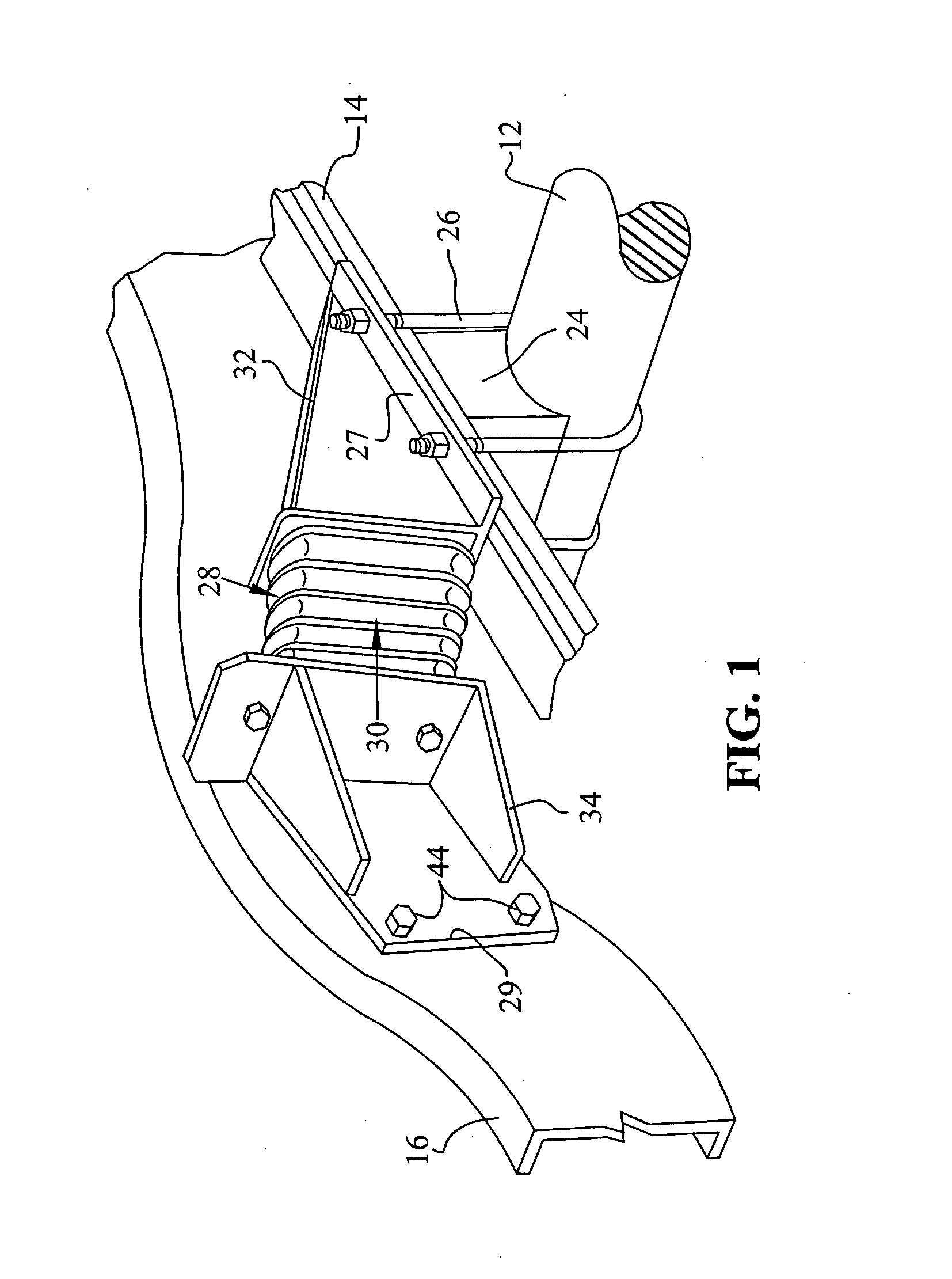

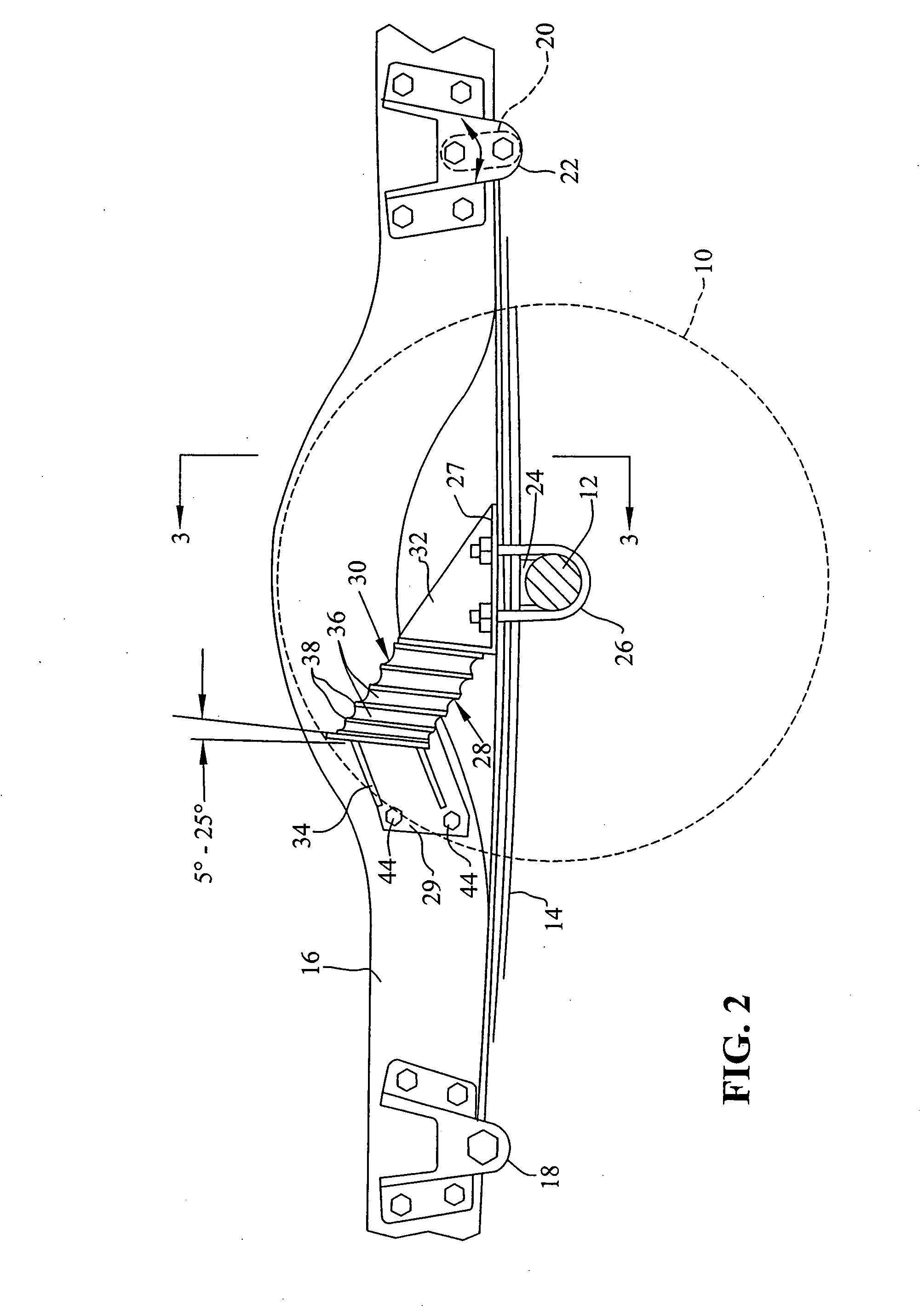

[0018] Referring now to the drawings, a vehicle as partially shown in FIGS. 1-4 includes a wheel 10 shown in broken line form for illustrative purposes mounted to an axle 12. The suspension system for the wheel includes a leaf spring 14 secured to a vehicle frame member 16 with a fixed mounting bracket 18 connected to one end of the leaf spring and a shackle 20 connected to the opposite end of the leaf spring and carried by a second mounting bracket 22 attached to the frame member. Axle 12 is secured to leaf spring 14 with a leaf spring support block 24 disposed between the leaf spring and the axle and a pair of U-bolts 26 on either side of the leaf spring fastened around the axle. The U-bolts 26 extend through the anchor plate 27 of a bolster spring suspension assembly 28 to secure the axle to the leaf spring 14. The opposite end 29 of suspension assembly 28 is secured to frame member 16 with bolts 44. End 29 of suspension assembly 28 is shown both laterally and vertically spaced f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com