Deck mounted pull riser tensioning system

a technology of tensioning system and riser, which is applied in the direction of drilling pipes, vessel construction, transportation and packaging, etc., can solve the problems of frequent maintenance of tensioner units, and achieve the effect of reducing the overall footprint of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

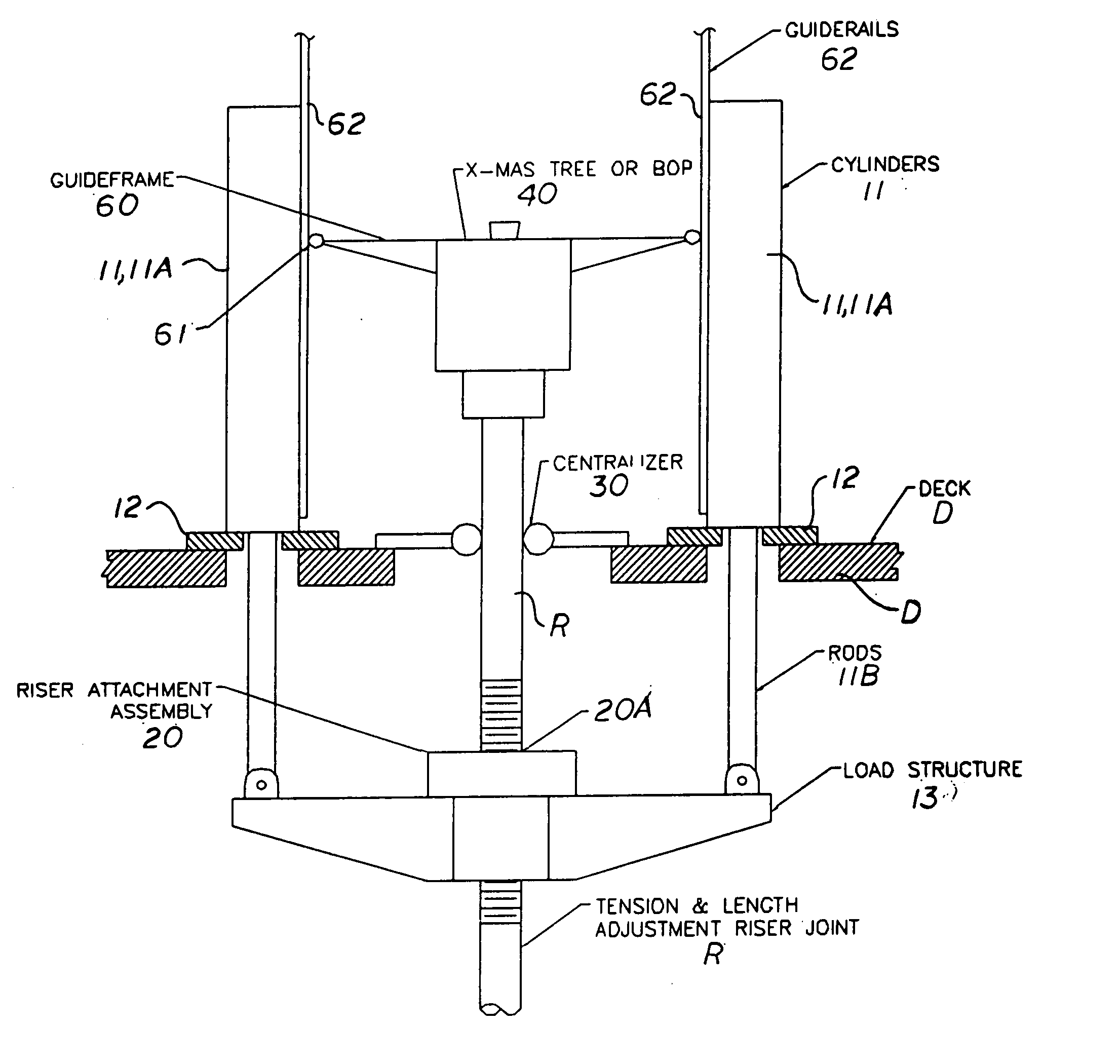

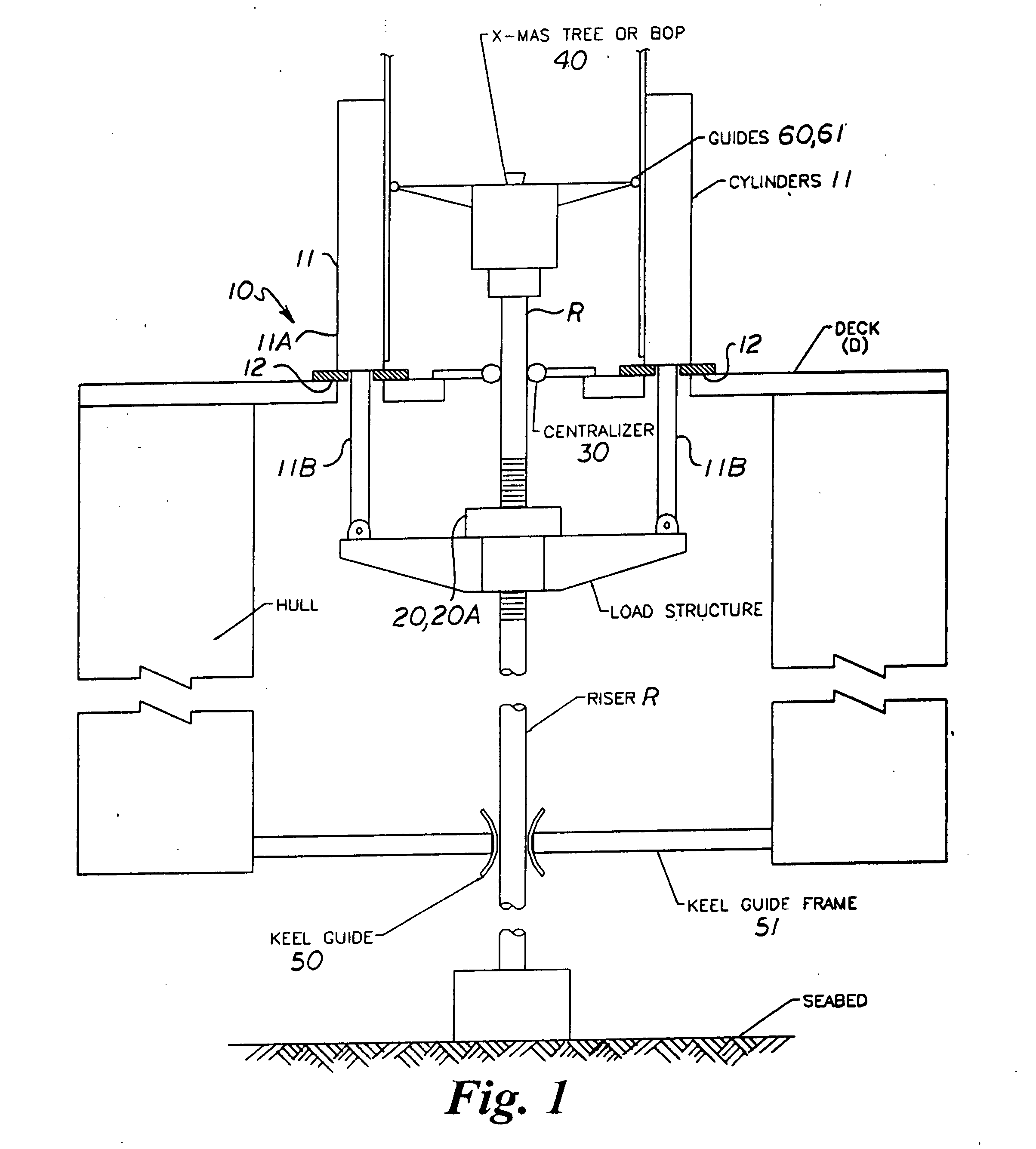

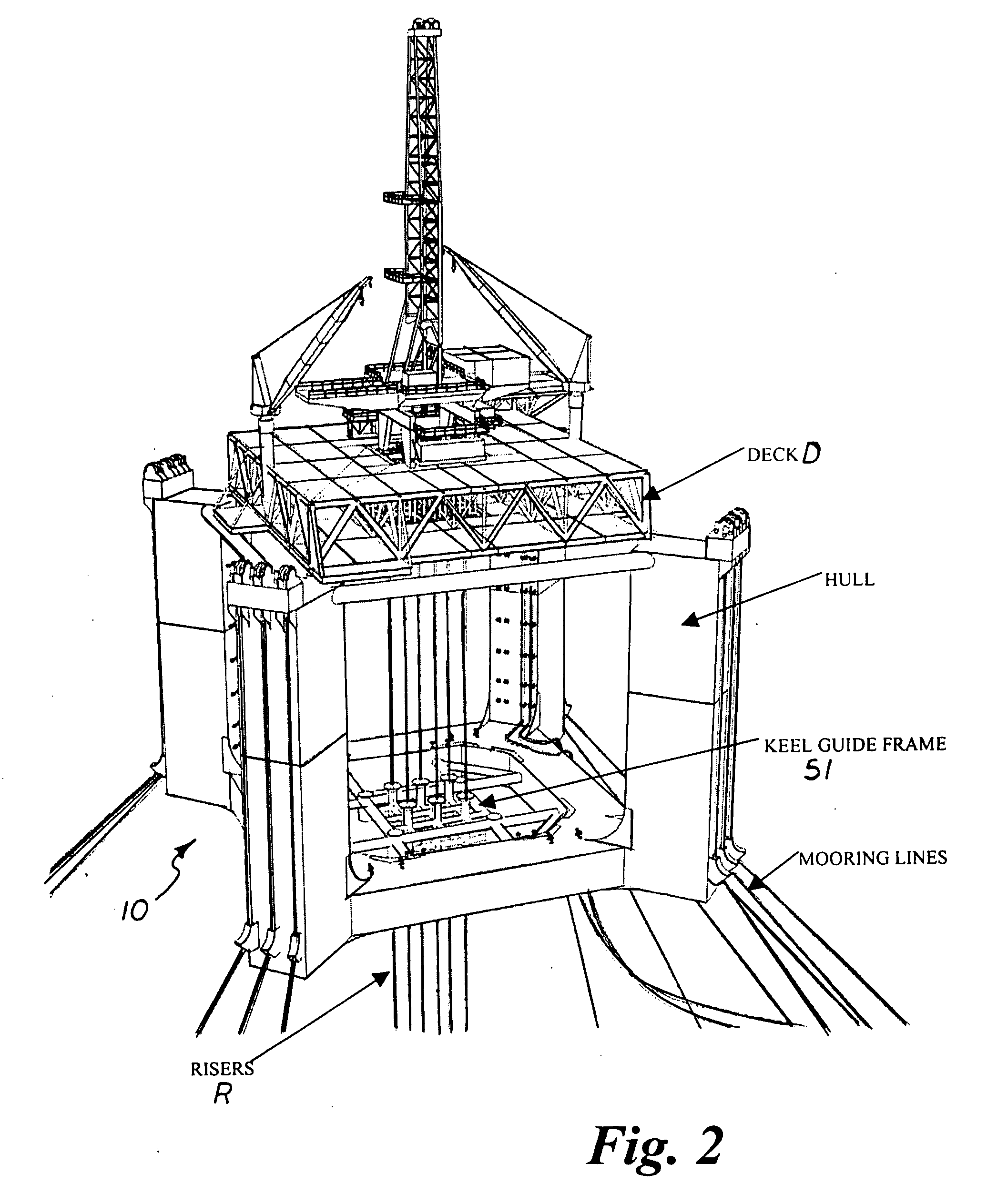

[0038] Several preferred embodiments of the present deck mounted riser tensioning system are described herein for use in tensioning a riser connected with a floating oil and gas drilling and / or production platform or vessel. As described hereinafter, the riser tensioning system utilizes multiple (at least two), direct acting tensioner cylinders configured in a manner to minimize the overall footprint of the tensioner system and to achieve maximum tensioner stroke with minimum overall length of the cylinders. Several preferred embodiments are described below wherein the tensioner cylinders are disposed in a vertical, a near vertical, or a vertically offset orientation, and supported at a lower deck level or upper deck level of the platform or vessel and may be rigidly fixed to the supporting deck or supported by various bearing supports to substantially prevent or to allow relative rotational movement between the cylinders and the deck on which they are supported.

[0039] In the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com