Pre-wired power distribution system

a power distribution system and pre-wire technology, applied in the direction of electrical apparatus casings/cabinets/drawers, lighting conductor installation, coupling device connection, etc., can solve the problem of impracticality in testing each wired installation for conformance to construction standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 200

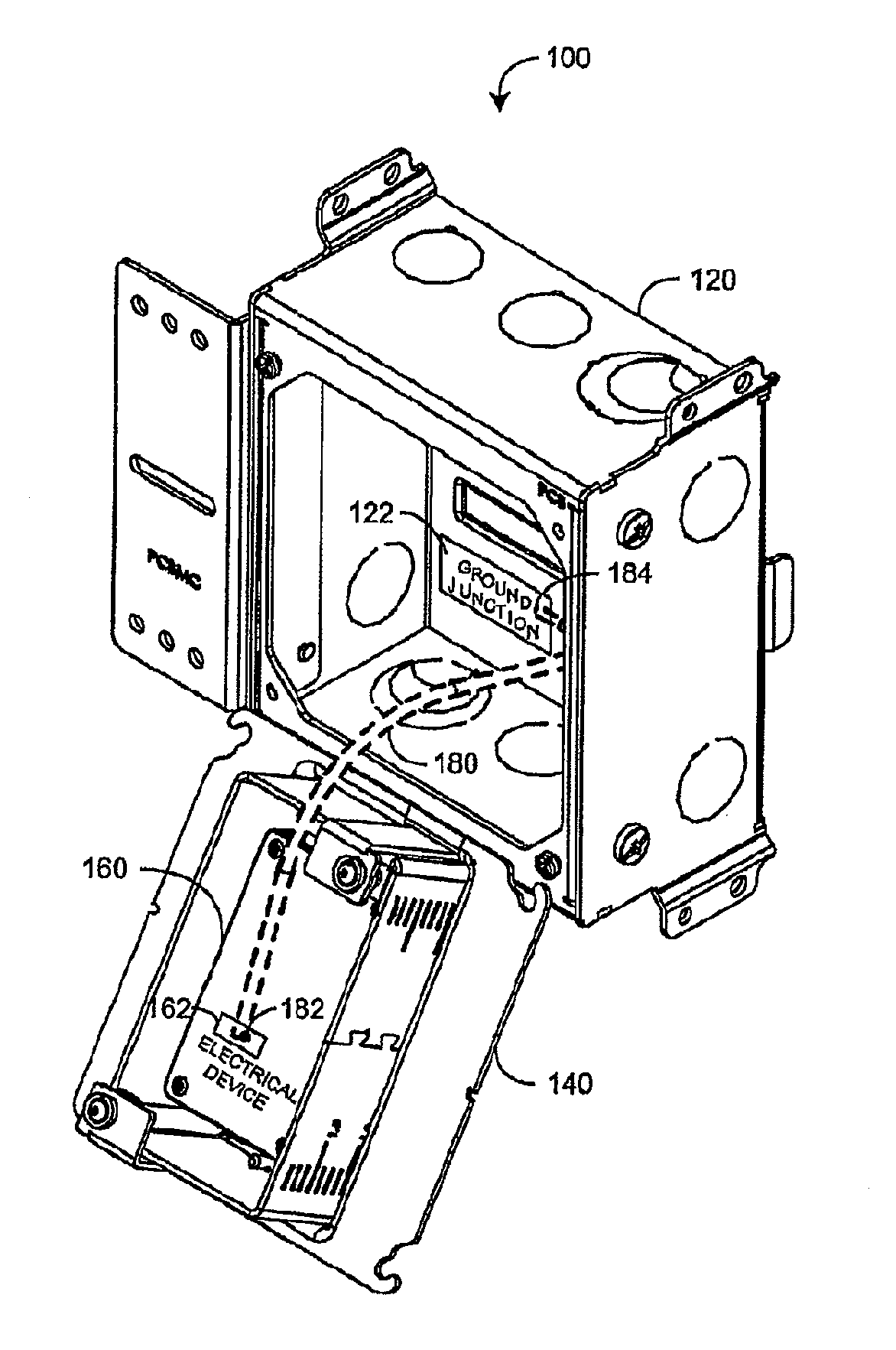

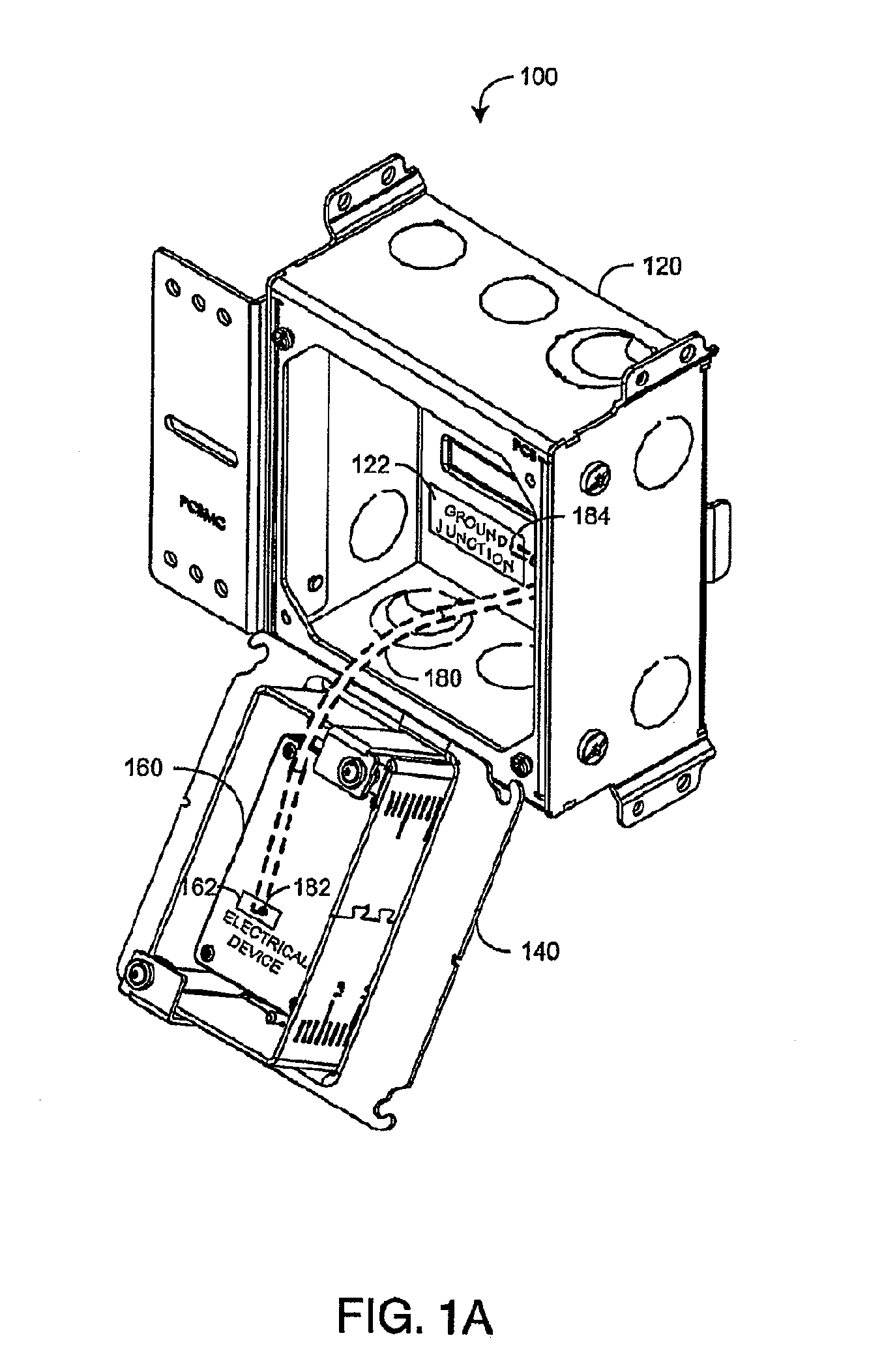

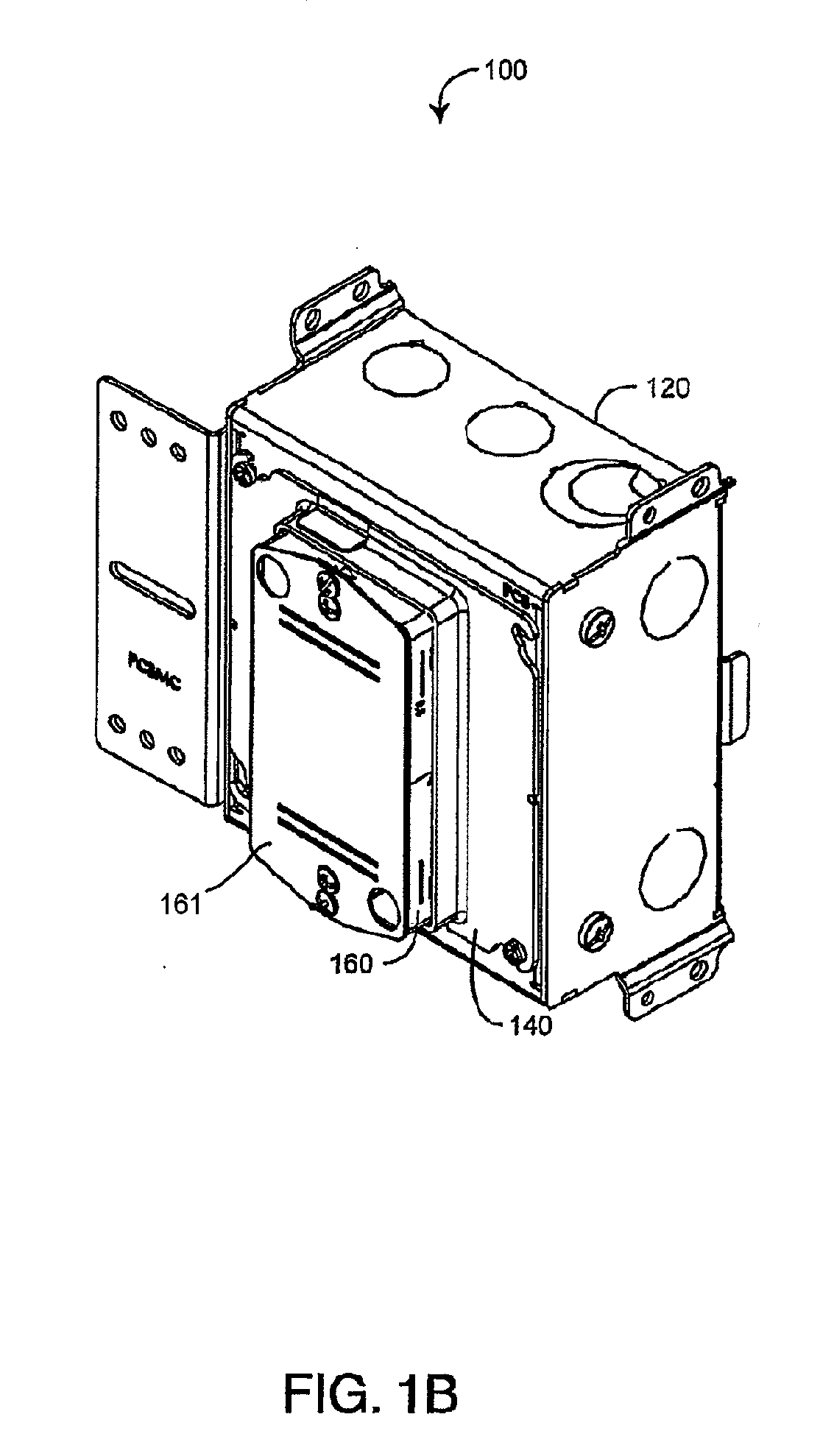

[0020]FIG. 2 illustrates a pre-wired power distribution system embodiment 200 having a wiring module 260 pre-wired with push-wire connectors 250. A ground wire 280 extends between the wiring module 260 and an electrical box 120. In some embodiments, the ground wire 280 includes a push-wire connector at some point along its length to be connected to a ground cable fed into the electrical box 120 along with other power distribution cables. The ground wire 280 has a first end 282 attached to a ground push-wire connector 252 and a second end 284 secured to a ground attachment point 222 in the interior of the electrical box 120. In some embodiments, the ground attachment point 222 is a screw terminal. The push-wire connectors 250 are connected to internal crimp wires of the wiring module 260 and adapted to accept power and ground wires from cables (not shown) routed to the electrical box 120. An electrician can easily and quickly attach the power wires to the appropriate push wire connec...

embodiment 300

[0021]FIG. 3 illustrates another pre-wired power distribution system embodiment 300 having a wiring module 360 with internal push-wire connectors 350. A ground wire 280 extends between the wiring module 360 and an electrical box 120. The ground wire 280 has a first end 282 attached to a ground push-wire connector 352 and a second end 284 secured to a ground attachment point 222 in the interior of the electrical box 120. The push-wire connectors 350 are adapted to accept power and ground wires from cables (not shown) routed to the electrical box 120.

[0022]FIG. 4A is a front perspective view of an embodiment of a wiring module 460 having internal push-wire connectors 407. The wiring module 460 has a mounting bracket 406 with an aperture 401 to mount the wiring module 460 to an adjustable plaster ring (e.g., 140) and an aperture 402 to attach a protective cover (e.g., 161) to the wiring module 460. The wiring module 460 also includes shielded connectors 403 for receiving a functional m...

embodiment 500

[0025]FIG. 5 illustrates a pre-wired power distribution system embodiment 500 having a 3-gang electrical box 520, a 3-gang adjustable plaster ring 540, a ground bus bar 550 mounted directly to the electrical box 520, three wiring modules 560 attached to the plaster ring 540 and a multiple wire ground lanyard 580. The ground lanyard 580 extends between the bus bar 550 and ground terminals 562 on each of the wiring modules 560. The bus bar 550 is configured to accept additional ground wires from power cables routed to and from the electrical box 520. As such, the ground lanyard 580 supports the plaster ring 540 in the open position shown, providing a wiring platform for the electrician to wire all three wiring modules 560 as a unit without having to handle and hold each of the wiring modules individually during the wiring process.

[0026] Advantageously, the bus bar 550 is configured to allow the attachment of multiple ground wires 580 so as to provide ground connections for not only wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com