Burner structure

a burner and burner technology, applied in the direction of burners, combustion types, pulverizing fuel combustion burners, etc., can solve the problems of difficult to achieve the desired distribution rate of the rich portion nozzle, affecting ignition performance or combustion stability, etc., to achieve low combustibility, high ignition performance and combustion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

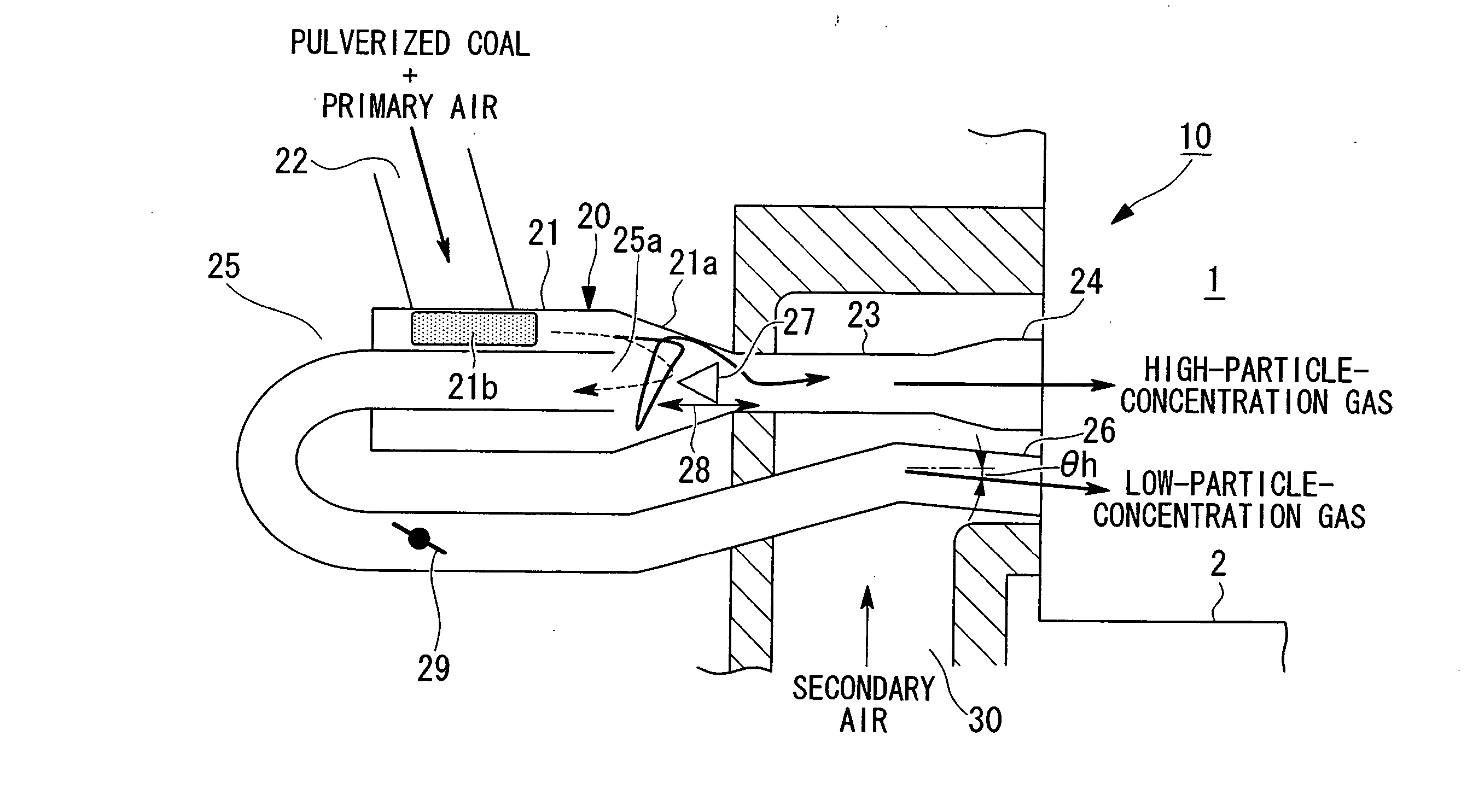

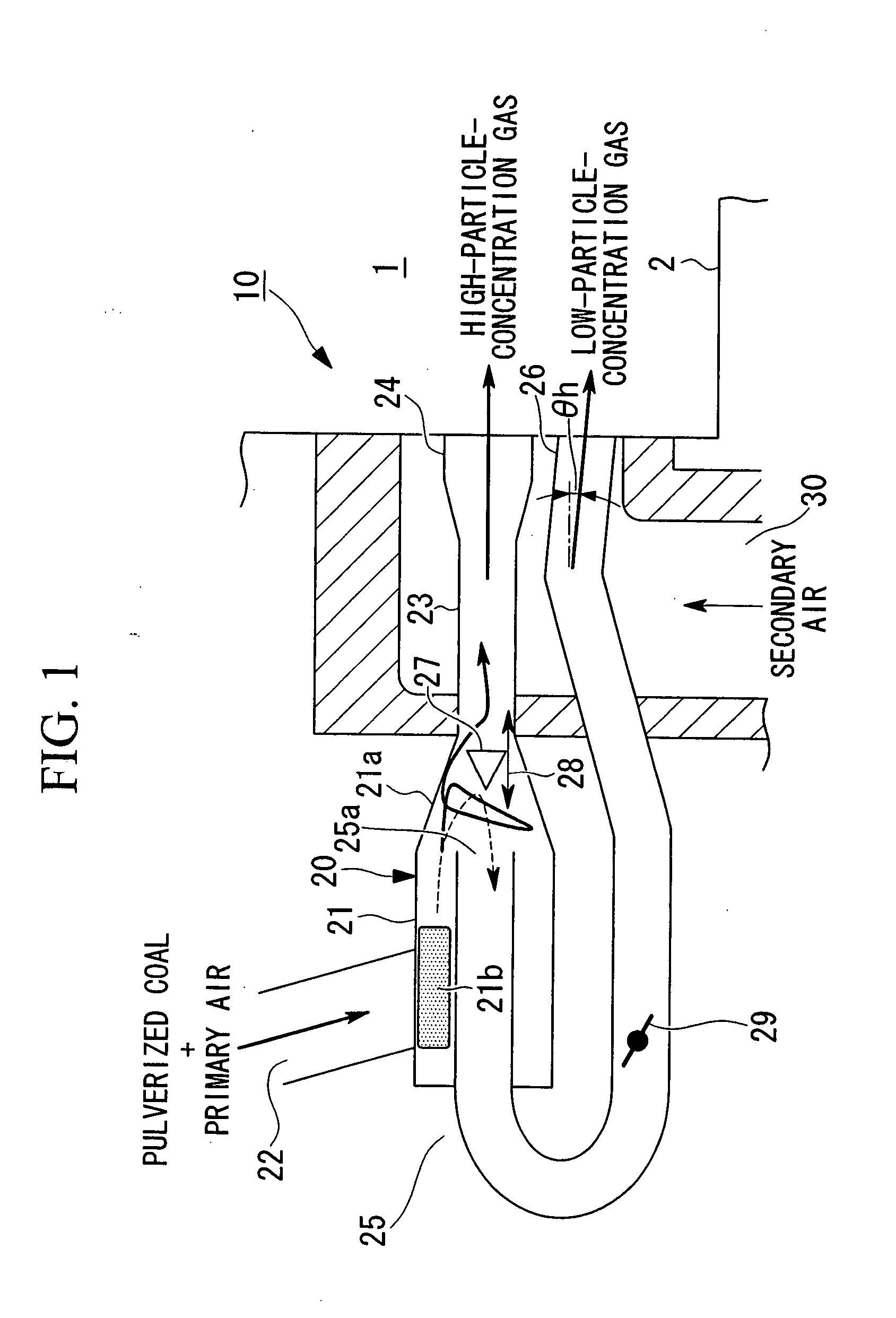

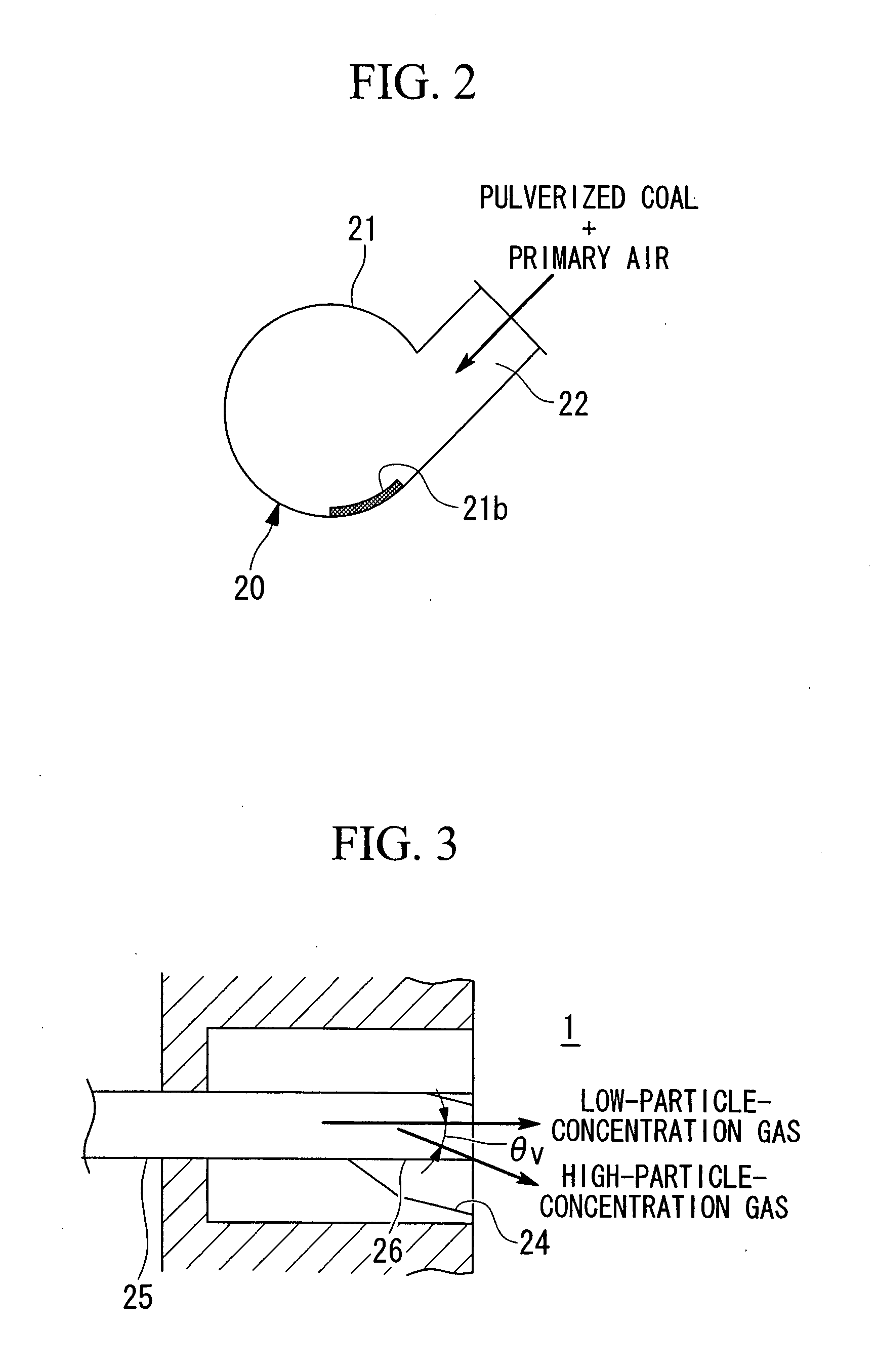

[0033] Hereinafter, an embodiment of a low combustibility fuel firing burner according to the present invention will be described with reference to the accompanying drawings.

[0034] A low combustibility fuel firing burner (hereinafter simply referred to as “burner”) 10 of FIGS. 1 to 3 is provided in, for example, a furnace 1 of a pulverized coal boiler or the like. The burner 10 burns a powder (fine powder) of a low combustibility fuel supplied together with an air in the furnace 1. Specific examples of the low combustibility fuel include anthracite and petroleum coke.

[0035] The following description is directed to the burner 10 supplied with a fuel that is pulverized coal obtained by pulverizing anthracite as a low combustibility fuel.

[0036] The burner 10 is composed of a pulverized coal supply system supplied with pulverized coal together with a primary air at a relatively low temperature, about 100° C., and a secondary air system supplied with a secondary air at a relatively hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com