High strength fin louver design

a technology of louvers and fins, which is applied in the direction of tubular elements, lighting and heating apparatus, and stationary conduit assemblies, etc., can solve the problems of low overall thermal efficiency of heat exchangers, louvered fins, and unlouvered fins, so as to improve the strength of heat exchangers. , the effect of high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

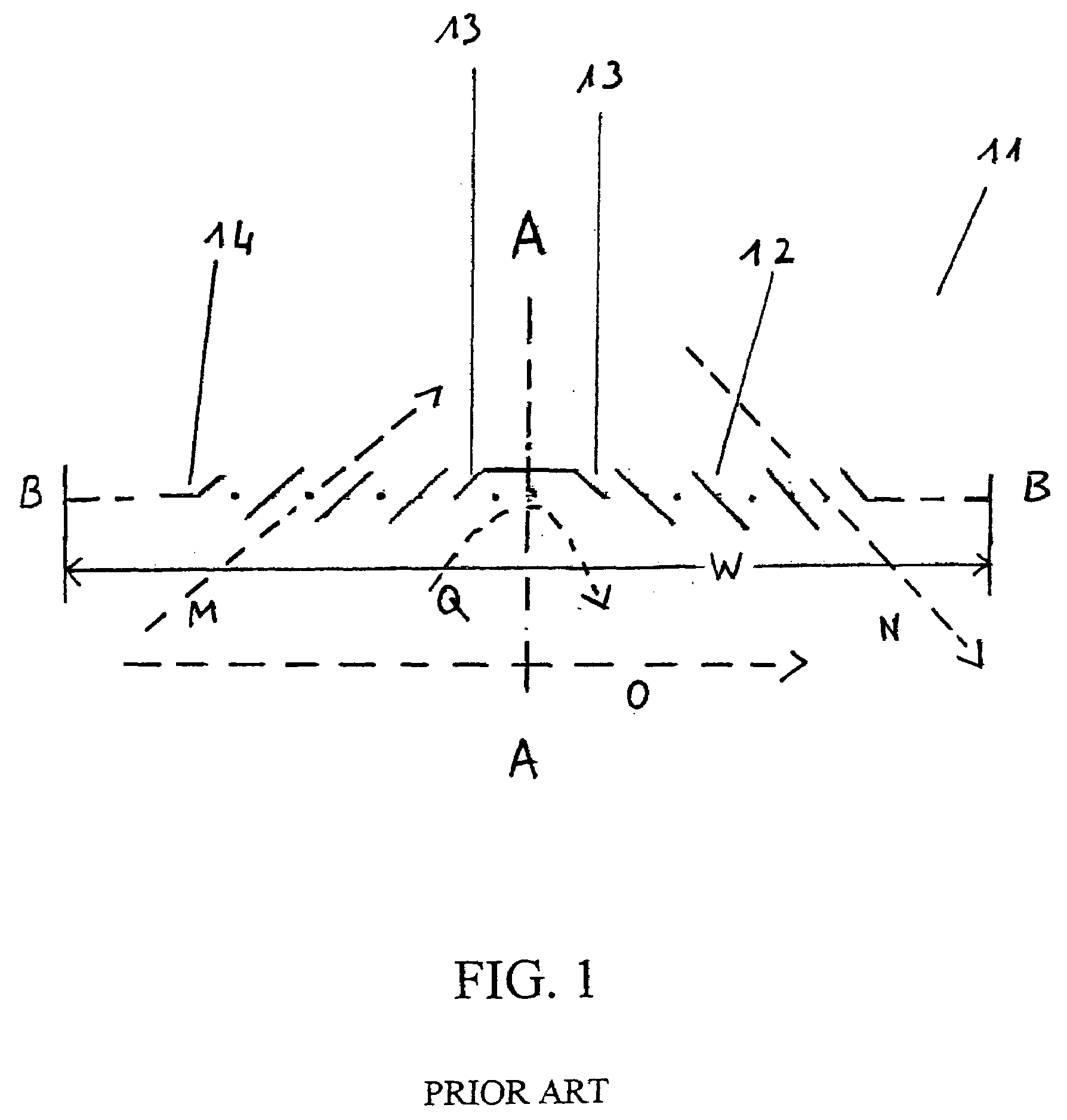

[0035]FIG. 1 illustrates a prior art fin (11) having louvers (12, 14) in a pattern symmetrical around line A - - - A and oriented in a column Axis (A - - - A) represents fin length direction. M represents air flow through one block of non three-piece louver. N represents air flow through another block of non three-piece louver. Q represents air flow at reversal louver. Breaking louver (14), non three-piece louver (12) and reversal louver wings (13) are shown.

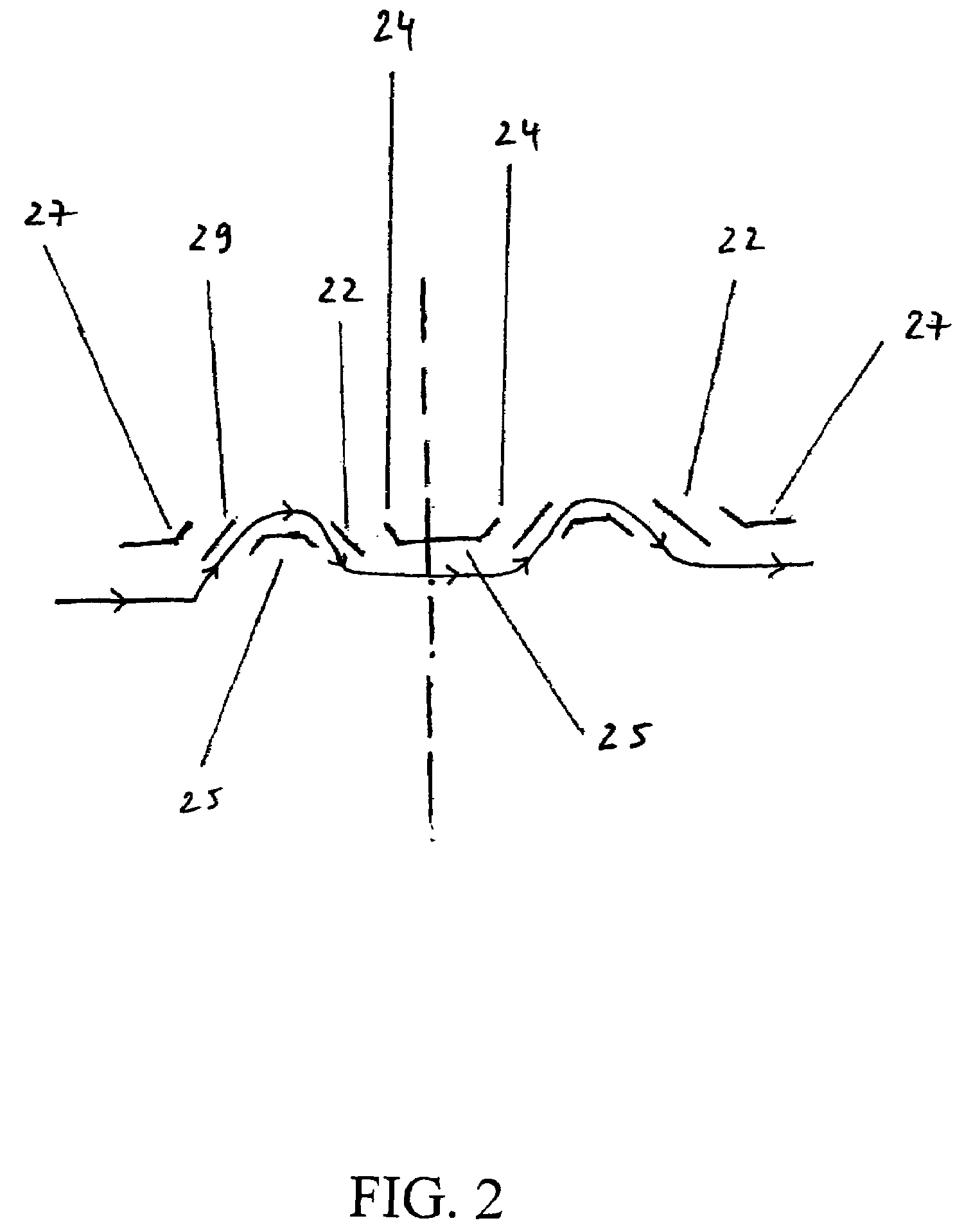

[0036]FIG. 2 shows a fin design in which a non-streamlined inclined three-piece single louver (25) is a reversal louver and has two half louvers (24) and connected by a flat area. In this design, the two downward facing half louvers are along / with similar angles (α), having two opposite directions, therefore forcing air (F) to change flow directions, resulting in additional air side pressure drop.

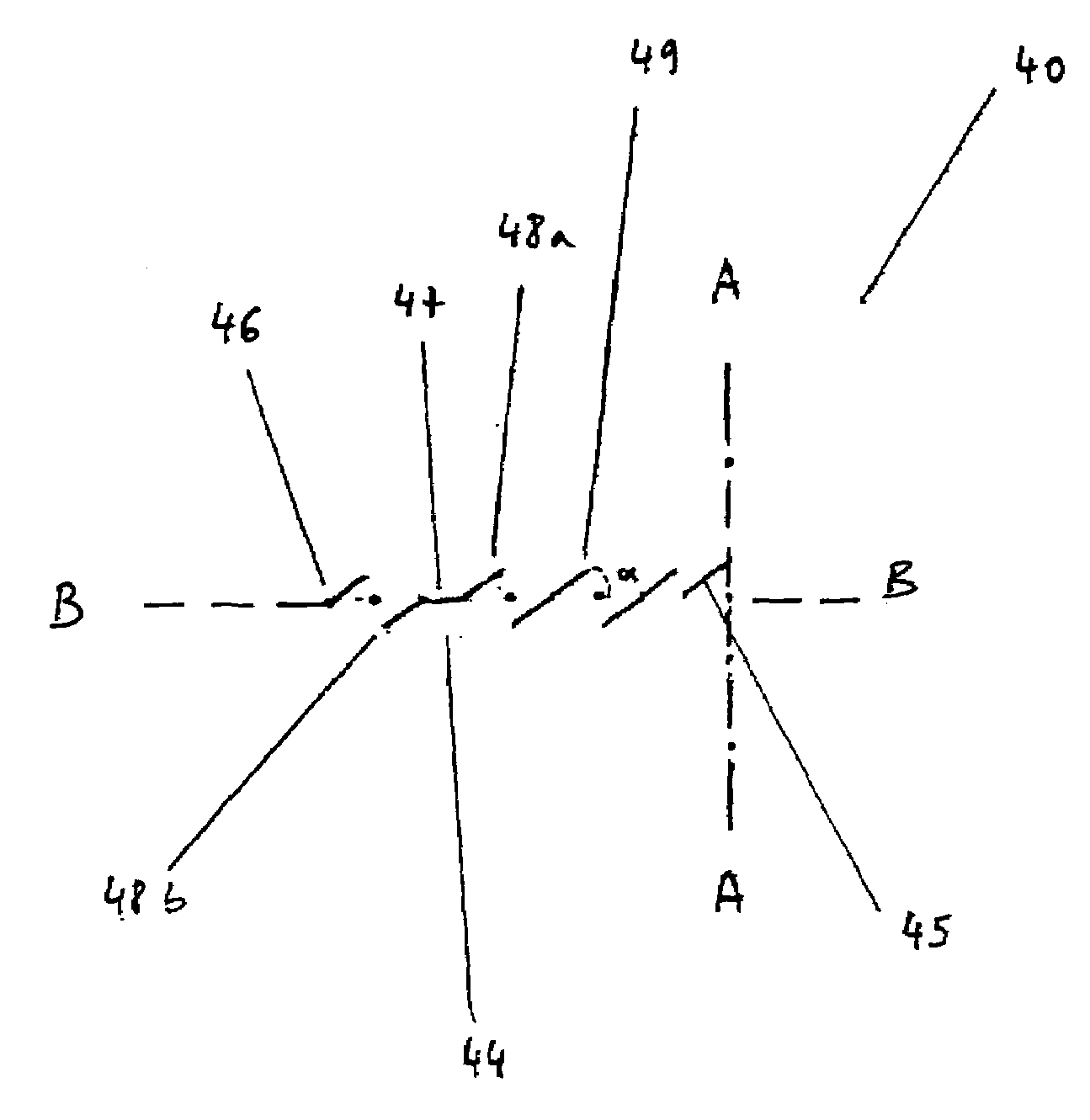

[0037]FIG. 3 illustrates a second louvered fin (31) having louver blocks (32a) (32b) arranged around a central axis (A - - - A), B - -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com