Buckle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

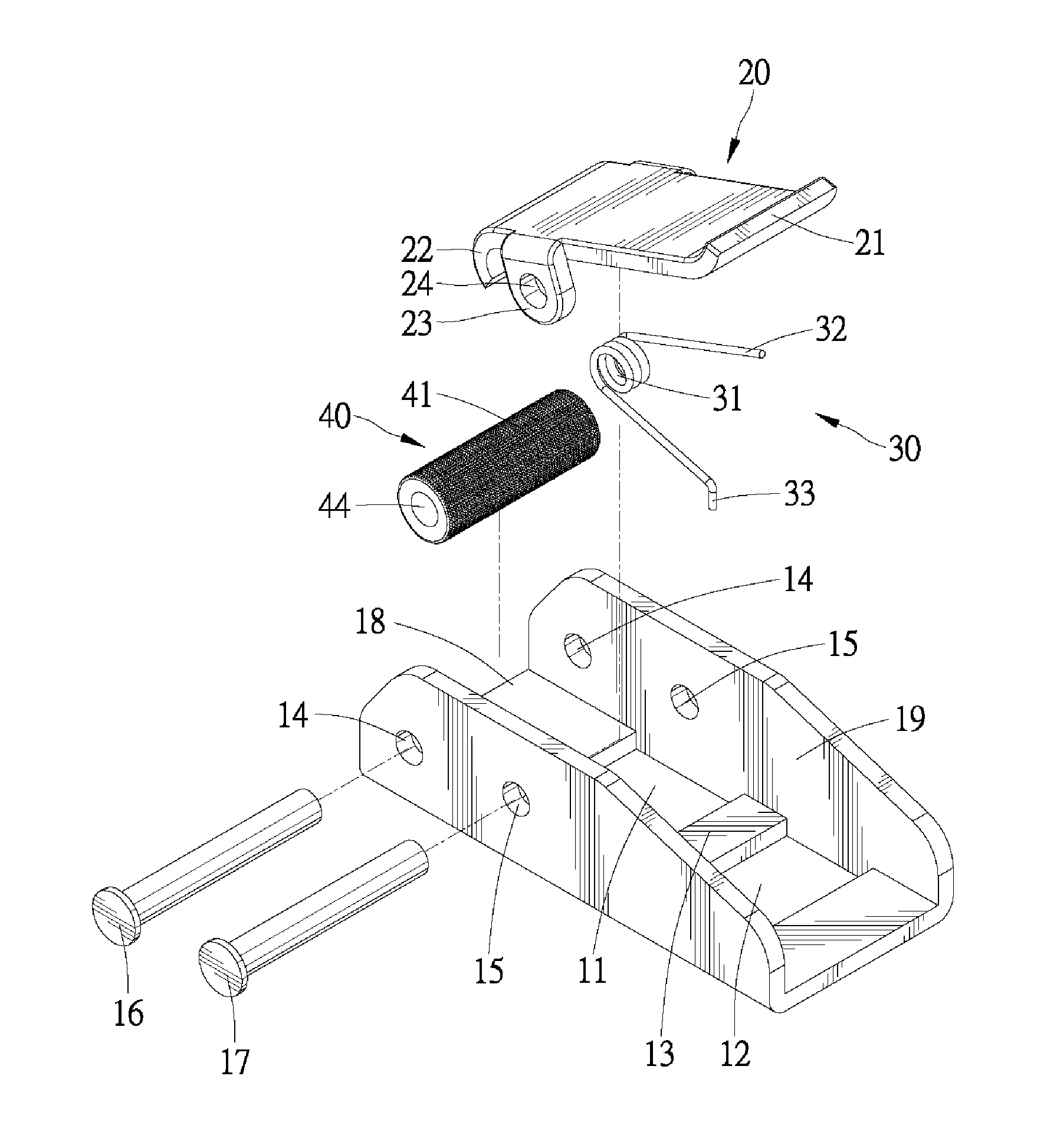

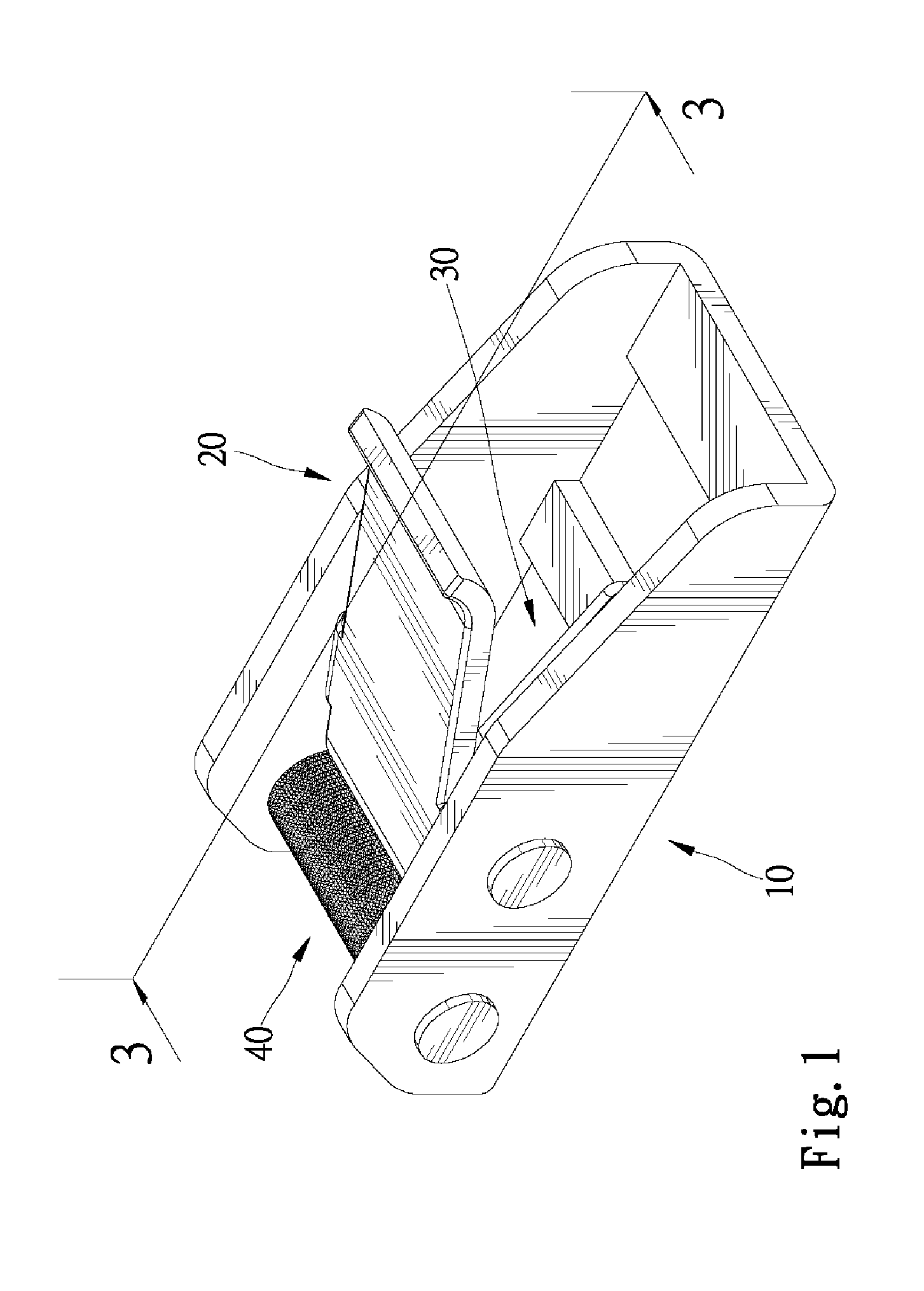

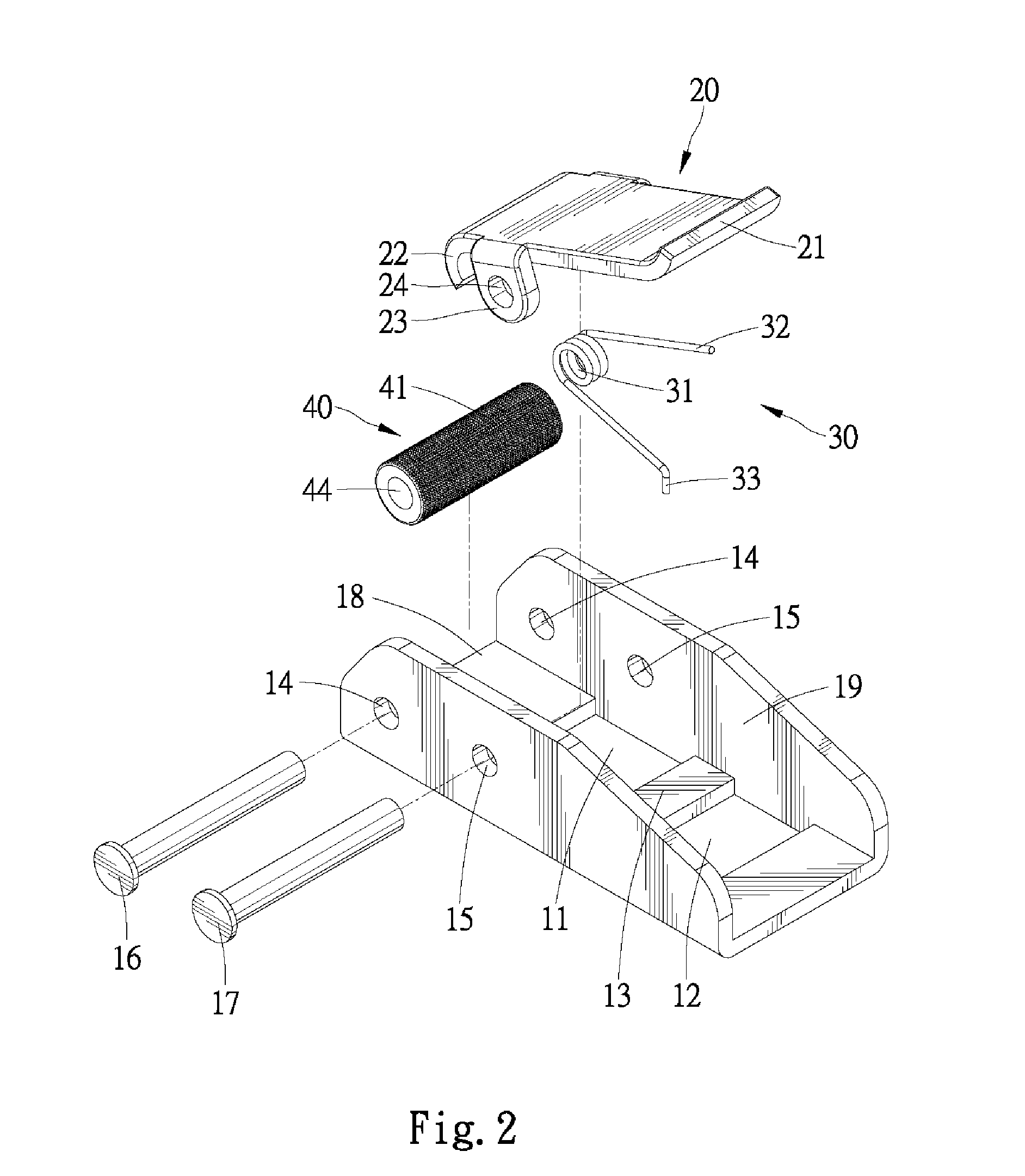

[0019]Referring to FIGS. 1 and 2, there is shown a buckle for fastening a strap according to a first embodiment of the present invention. The buckle includes a base 10, a handle 20, an elastic element 30 and a jaw 40. The base 10 and the handle 20 are made of iron in a continuous pressing or punching process with ease at a low cost.

[0020]The base 10 is made of a first iron sheet including a middle portion and two lateral portions. In the continuous pressing process, the lateral portions of the first iron sheet are bent with respect to the middle portion of the same so that the former extend perpendicular to the latter, i.e., the base 10 is U-shaped in an end view. The middle portion of the first iron sheet becomes a floor 18 while the lateral portions of the same become walls 19. Two openings 11 and 12 are made in the floor 18. The openings 11 and 12 are separated from each other by a crossbar 13 that is part of the floor 18. Two apertures 14 and 15 are made in each of the walls 19....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com