Light-emitting diode structure and method for manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

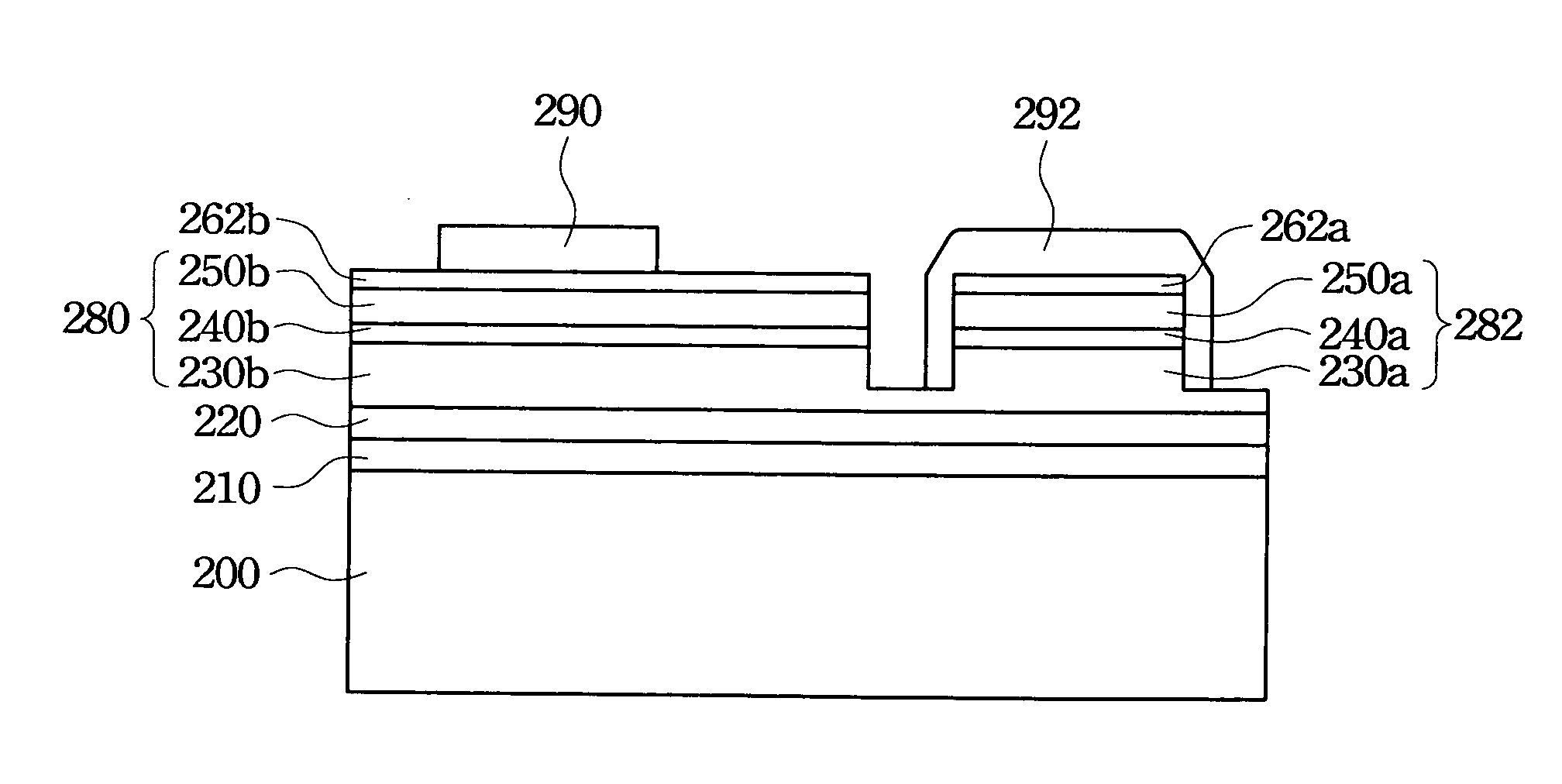

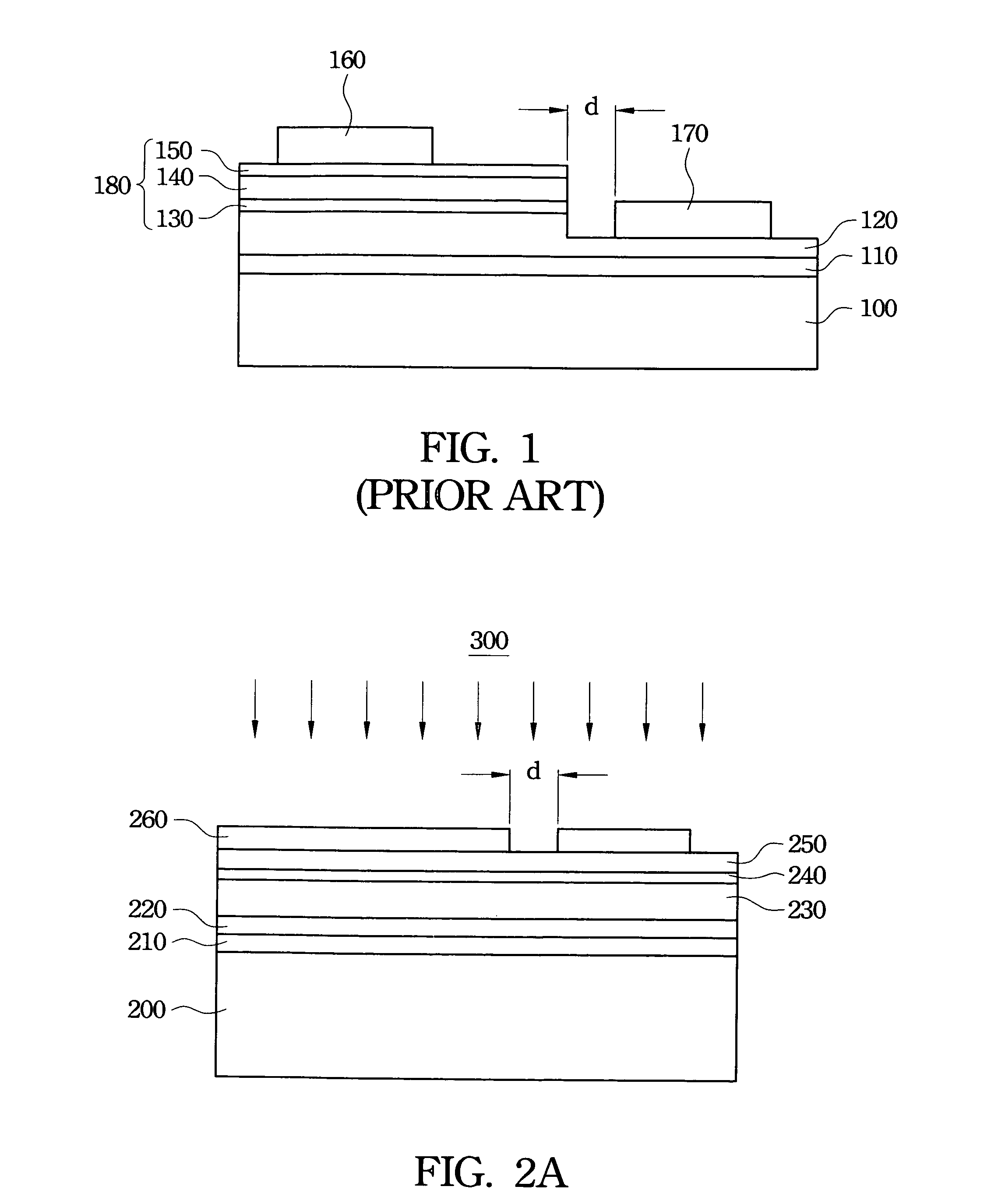

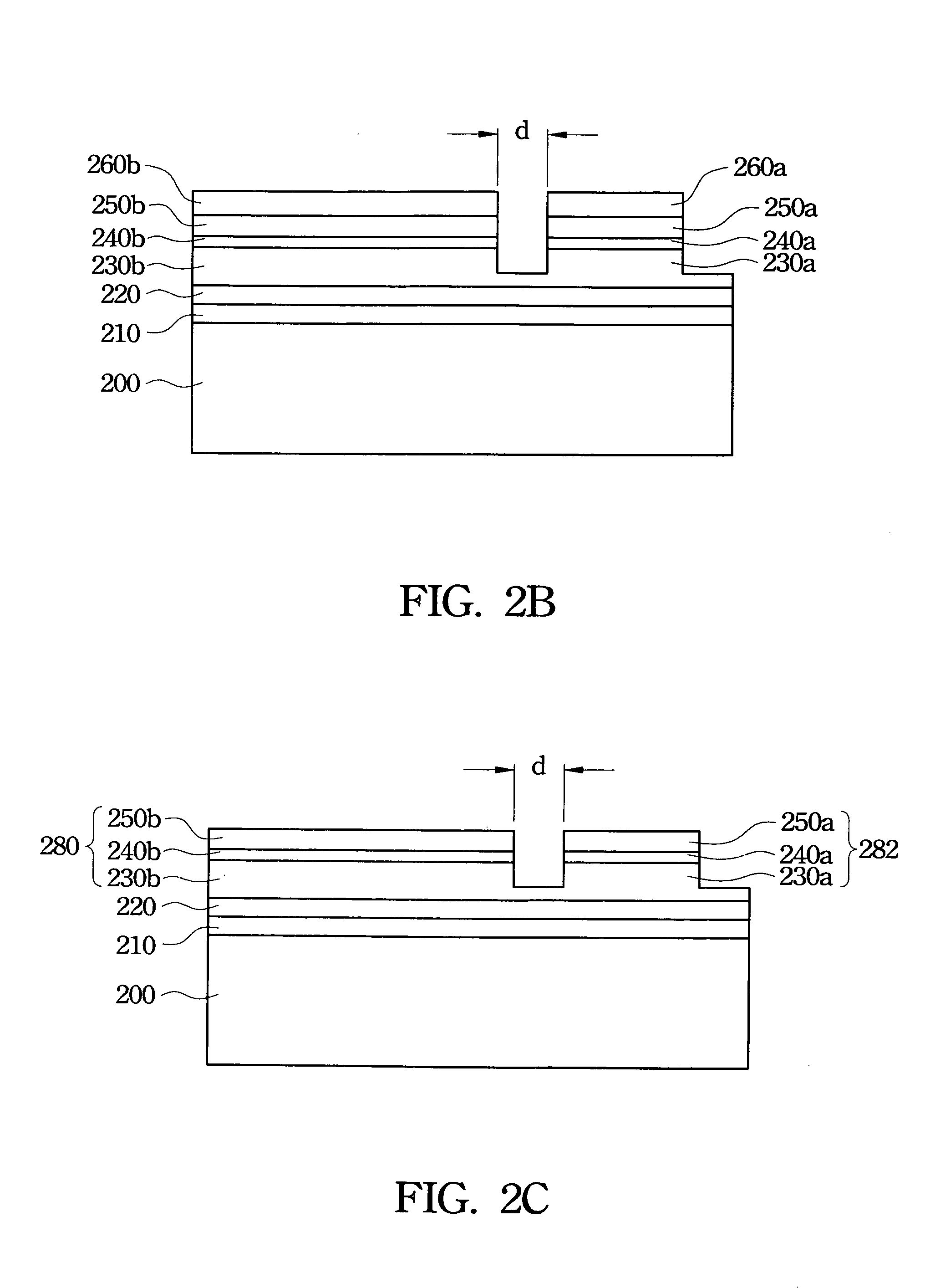

[0016]An embodiment of the present invention shown hereinafter is used to resolve the problem of poor image recognition and rough surface textures caused by different levels of surface roughness of the epitaxial layers under two respective electrode pads. The embodiment of the present invention reserves a complete epitaxial structure (protrusive structure) in the area under a n-type electrode pad, and the protrusive structure is substantially equivalent to a light-emitting epitaxial structure under a p-type electrode pad, wherein the thickness of the material layers forming the protrusive structure is smaller than or equal to the thickness of the material layers forming the light-emitting epitaxial structure, thereby making the surface roughnesses of the epitaxial layers under these two electrode pads as similar as possible, thus resolving the problem of rough surface textures. Moreover, a portion of the n-type electrode pad directly contacts a n-type epitaxial layer so as to assure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com