Method, system, and computer program product for predicting thin film integrity, manufacturability, reliability, and performance in electronic designs

a technology of electronic design and manufacturability, applied in the direction of semiconductor/solid-state device testing/measurement, testing circuits, instruments, etc., can solve the problems of patchy solutions provided by conventional methods and systems without addressing the root causes of problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

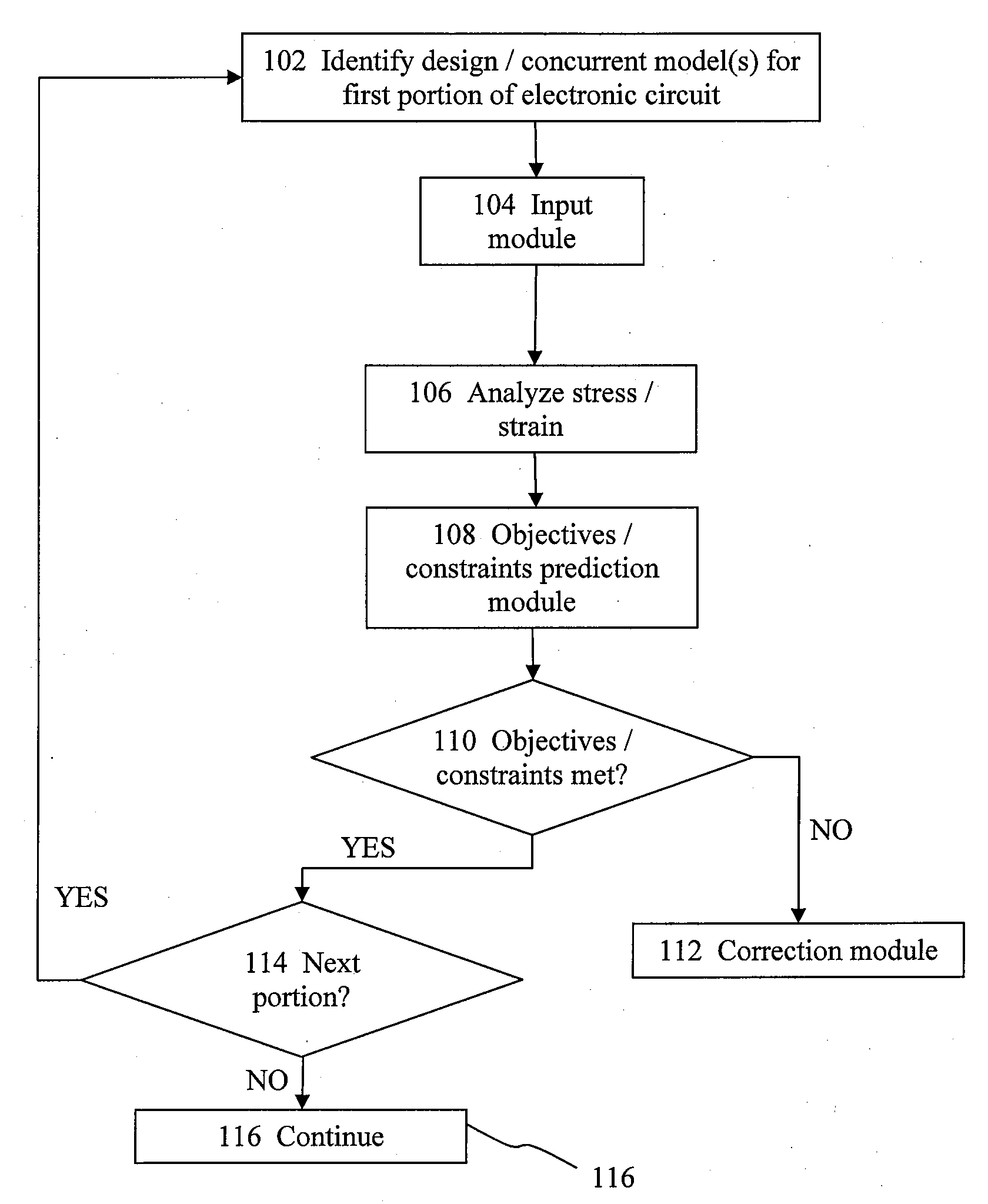

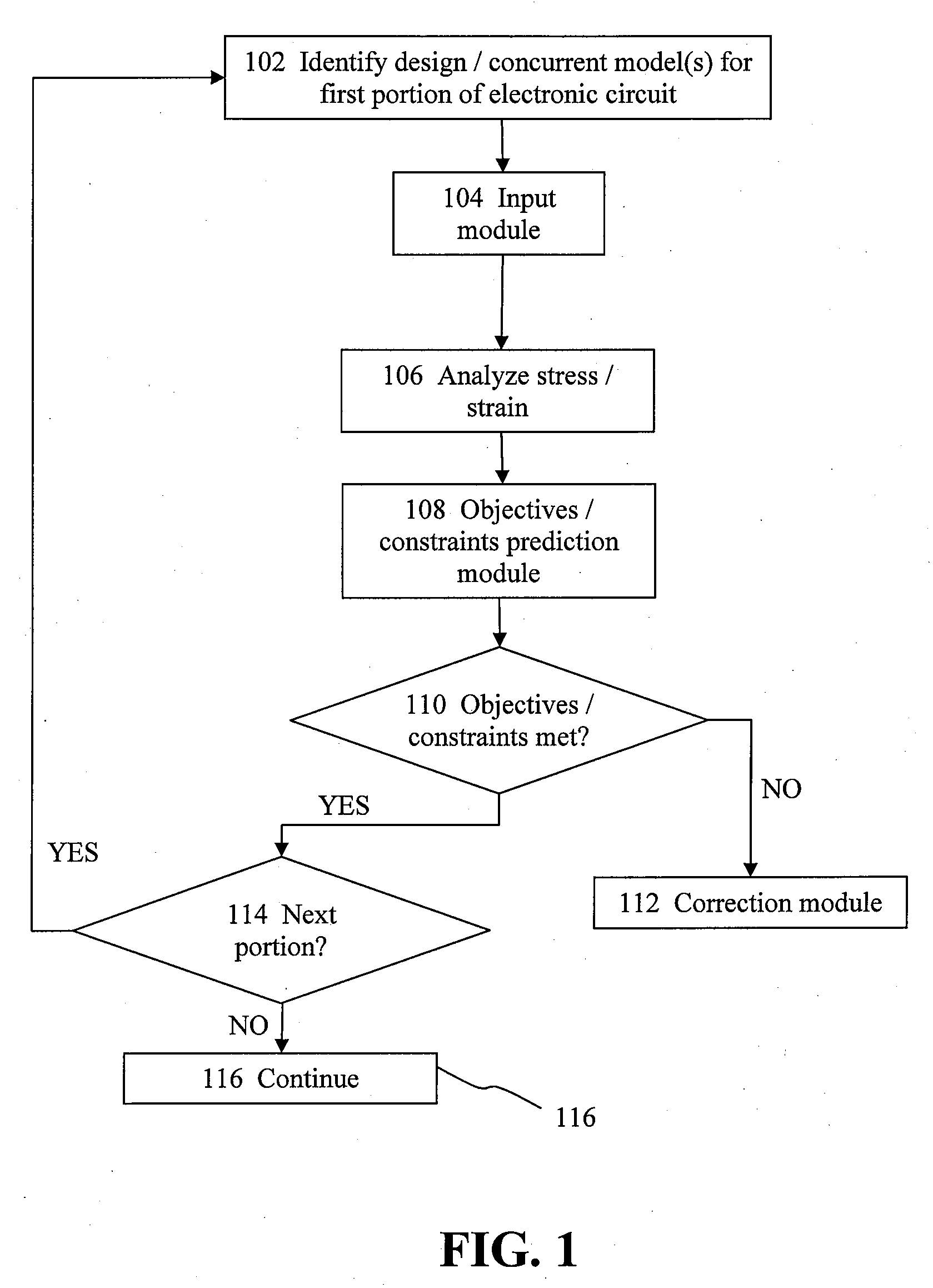

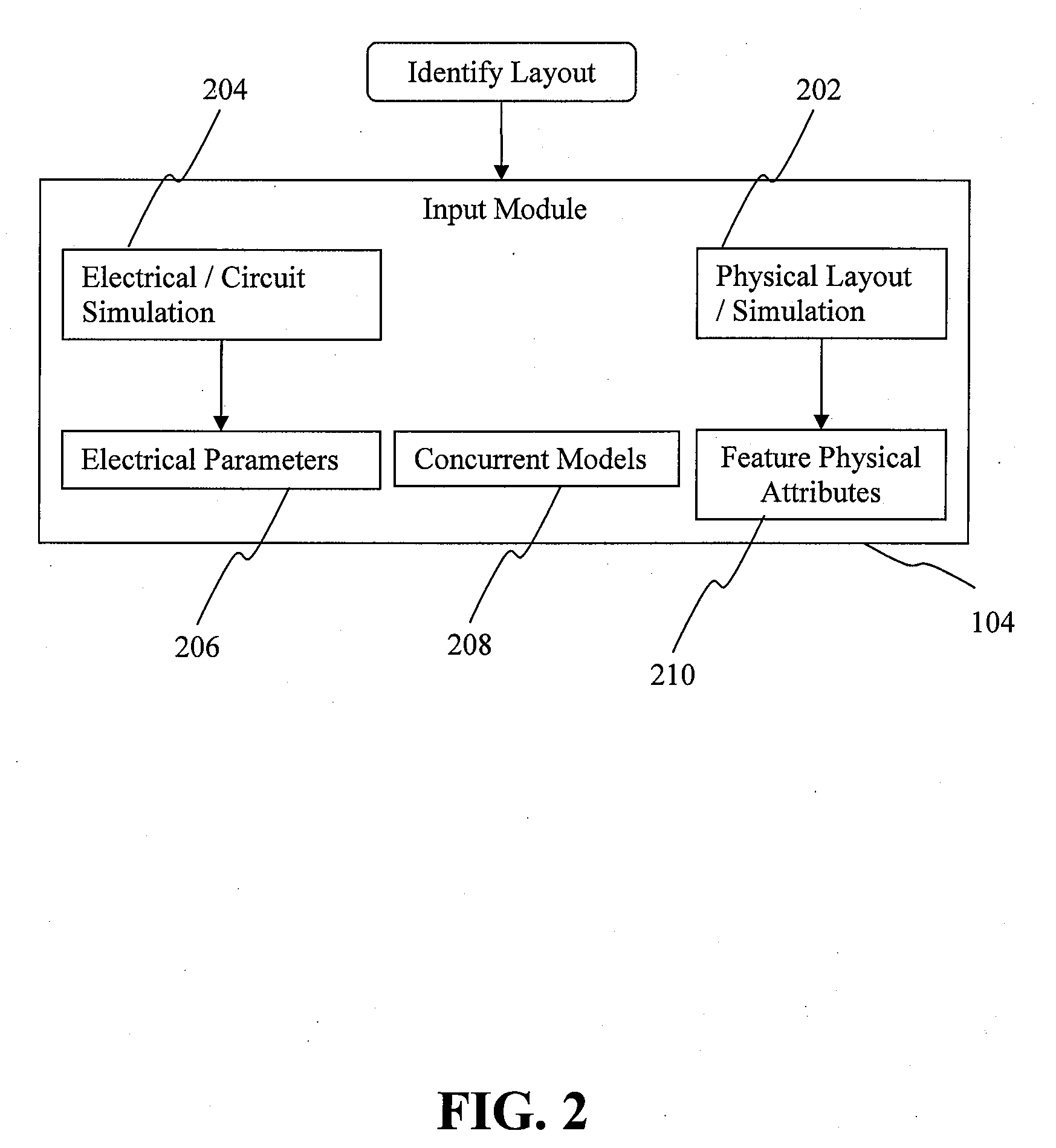

[0021]The present invention is directed to an improved method, system, and computer program product for evaluating the stresses or strains within various layers or parts of an integrated circuit or an electronic circuit with the aid of the one or more concurrent models for the manufacturing of the electronic circuit or the design layout to predict whether the electronic designs meet certain design criteria. Some embodiments utilize the above method, system, and / or computer program to evaluating stresses within various layers of an integrated circuit with the aid of the design layout and the one or more concurrent models for the manufacturing processes or techniques to compute the non-planarity of the films. As noted above, conventional methods and systems provide patchy solutions without addressing the root causes of the problem.

[0022]Referring to FIG. 1, the method or the system of several embodiments of the invention first identifies a first portion of the integrated circuit (IC) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com